| VonGruff |

| (.400 member) |

| 17/02/15 05:07 PM |

|

|

after the recent thread on the Lee Speed 405 Winchester I thought I would start a thread on my version of the 405 Winchester on a Lee Speed styled rifle.. This is how the project came together.

I had been wanting a big brother for the 303 Lee Speed I did a while back ( http://forums.nitroexpress.com/showflat.php?Cat=0&Number=248874&an=0&page=0#Post248874) and in a couple of email conversations with forum members the two contenders I was trying to decide on were between a 375 or a 40 cal. The 40 won out and I was generously given a BSA commercial action so with a bolt and stock bolt from my own parts box, had the start to what I wanted to do.

I intended to make a similar wrist mounted aperture sight so set out to make the filler plate for the lobbing sight recess

| VonGruff |

| (.400 member) |

| 17/02/15 05:08 PM |

|

|

The next thing was to re-contour the rear of the action socket to give it the 'Lee Speed" radiused top rather than the almost square top of the standard action.

| VonGruff |

| (.400 member) |

| 17/02/15 05:11 PM |

|

|

I then Spent a little time and made the aperture sight. Nothing fancy (or spendy) but similar to the one I made for the 303 which was a success so this is just more of the same.

It is about as low over the dust cover as possible which keeps the cheek weld right on the butt and makes for a front sght that is not abnormaly high. What it does require is that the rear lug for the dust cover is ground down to about half its height but I found that out when one of the bolts I got had the lug treated like that and it does not negatively effect the visual or the holdability of the single remaining lug that is not ground.

| VonGruff |

| (.400 member) |

| 17/02/15 05:14 PM |

|

|

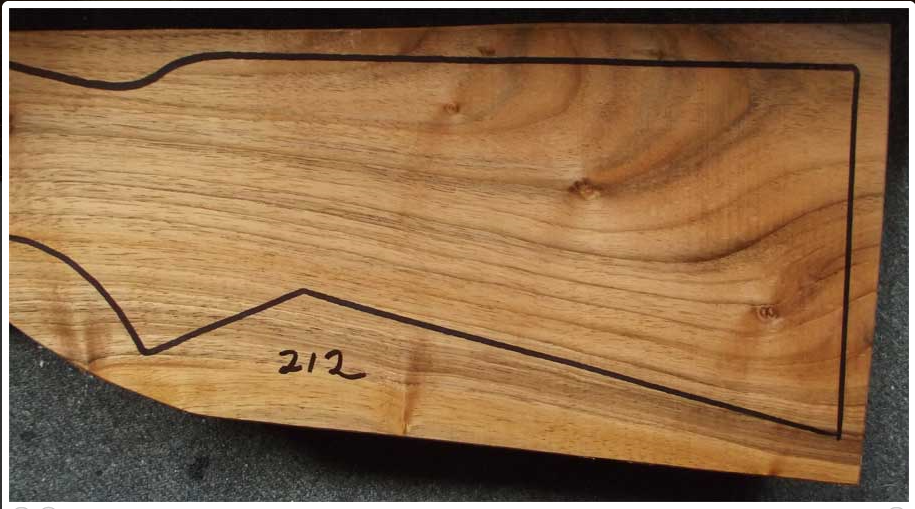

The next step was to look at stock blanks and had semi selected 3 from a plain but well grained one to a nicely marked 1/4 sawn one to a flat sawn one with more grain but no colour but after a conversation with Brian (from NZ Walnut Supplies) I bought this blank..

The other side is not as well figured but I think that if I set the stock well to the right side of the blank I will cut back into a bit more figure.

This is the walnut supply outlet http://www.nzwalnut.co.nz/

| VonGruff |

| (.400 member) |

| 17/02/15 05:27 PM |

|

|

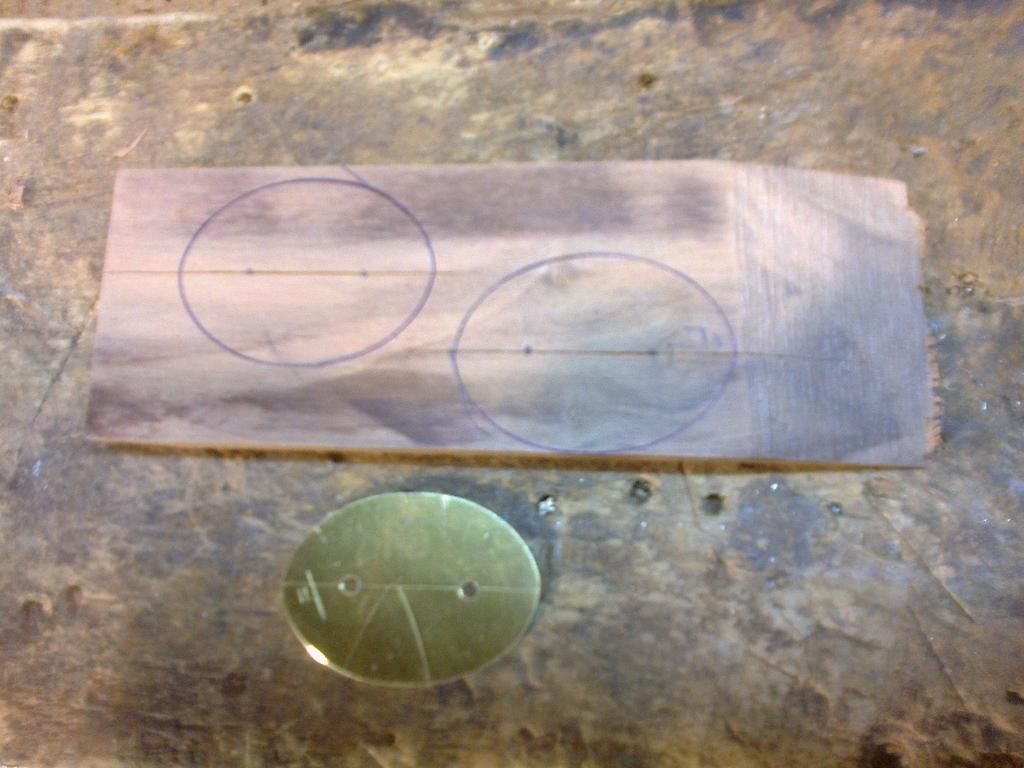

Laying out the pattern

Because I have a few more Lee speeds to do after this one I decided to make a framed pattern so I could lay it on the blank and actually see the grain rather than drawing around the pattern then seeing I needed to shift it a bit. This way I can shift the framed pattern round to the most advantageous position, mark two location spots on it and then mark out the pattern from the pattern board. It meant I did shift it from where I originally thought it would go but it will be better for the finished stock.

One of the chaps I had been talking to about the cartridge choice had wanted another 375-303 (he had had one years ago) so he sent down an action and we organised another blank so I could do the two of them in tandem. Having the guides set up for drilling the stock bolt hole I did mine in the mornig then got the second one done in the afternoon so they were both at the same stage.

| VonGruff |

| (.400 member) |

| 17/02/15 05:34 PM |

|

|

After marking out the action lines, I use the hack saw (fine teeth + fine cut) and cut down to within cooee of the mark and only forward to the rear of the receiver ring.

and a few minutes with a sharp chisel gets the inletting started.

Next step was to find the dimensions of the mag wall and start an undersized hole though the wood.

One hole at 24mm and the front three at 20mm had it started.

Finding out the back of the trigger group recess came next and again all cut undersize.

and a little chisel work had it opened up to where I would just get clearance vertically

| VonGruff |

| (.400 member) |

| 17/02/15 05:37 PM |

|

|

Turning the forestocks over again I could then mark down the action lines and gradually take out the bulk of the wood with the grannies tooth hand router. The depth had been marked in earlier

Note the small mallet It is one I made and is just 6" long and weighs 6 oz. Sometimes it is better to tap lightly and trying to do that with the heavier mallet can cause an oops moment.

The action is stripped of the trigger and spring but the mag release bar stays in place. The top of the trigger housing is opened up with a rat tail file till the mag release bar on the action will just slip over it so the action can start into its first fitting at the rear of the inlet.

The recoil lug can be marked into place and chiselled down to the action flat

And with a little gouge work the start of the receiver ring can be taken out.

After this stage it will be all smoke and scrape work, so things will slow down a bit.

| VonGruff |

| (.400 member) |

| 17/02/15 05:41 PM |

|

|

Next up I took the lowered portion off the rear of the top side on the planer and filed a radius from the rear action flat onto the socket face. A quick look at this part of the action will show the need for the radius.

Then with a careful measurement I marked out to remove the majority of the wood to clear for the mag release lever anchor point which is the major "draw" that needs to fit tight so it was left proud and worried back as the smoked action was lowered into place by scraping with the bent file scraper.

With the draw roughed into place it was time to work on getting the action down into place. This bent and sharpened file (I ground off the teeth on both flats and edges befoe bending and sharpening) is almost indispensable for the job and far and away the most usefull way of working on the sides of the action inlet. I have previously used chisels etc to scrape but the bent file it the easiest to direct and use.

| VonGruff |

| (.400 member) |

| 17/02/15 05:42 PM |

|

|

So at 10 3/4 hours both actions are snuggled into the wood

| VonGruff |

| (.400 member) |

| 17/02/15 05:44 PM |

|

|

Just an hour on it today rechecking the inlet and getting the reinforce done across the rear of the socket face rather than through the rear of the stock as is done on the ex mil stocks. To get the position that will be at the centre of the triangle of wood that is left it is a simple matter to measure down to the centre of the through reinforce and transfer it to the new forestocks

Drill a series of holes and clean it out to take the end of a 3/16 machine screw

Set into place with Devcon steel, then with the action face given some Vaseline for mould release, the action can be set into place to make the rear flat against the socket face and to force it down against the main draw. It wil sit overnight and I can get back to it tomorrow.

| VonGruff |

| (.400 member) |

| 17/02/15 05:47 PM |

|

|

Todays effort has seen the trigger guard inlet on them both and the magazine well on one finished but 5 1/2 hours bent over the bench in the heat was enough for the day.

Worrying the t/g into place

Almost all the tricky stuff done now.

Then a little time in the shed gets the buttstock wrist into the socket and having an add up I see that I am 27 1/4 hours in to get them both to this stage. The top one (for the 375) has the mag cut-off while I didn't want to use one for my 400 but they are both ready for the barrels now although I can shape up the butts when I get the plates. Havent decided on the grip cap yet.

| VonGruff |

| (.400 member) |

| 17/02/15 06:03 PM |

|

|

Possibly a lessor move but I needed a pair of grip caps so made them from a nice straight grained walnut that should give a little contrast in colour but more importantly will protect the end grain

With that taken care of, I returned my attention to the top of the socket wrist. I had done a bit of filing to take away from the square top but after spending a bit of time looking at some Lee Speeds and having one in hand, I decided to take a bit more off it. and have ended up with what should give a nice slim topped stock wrist

| VonGruff |

| (.400 member) |

| 17/02/15 06:08 PM |

|

|

after consultation the 375-303 action was given the same wrist treatment, the TOTW checkered steel butt plates were fitted so I set to on the buttstocks and got some shape into them. Will not be able to do much more now till there are a couple of barrels threaded up.

| VonGruff |

| (.400 member) |

| 17/02/15 06:54 PM |

|

|

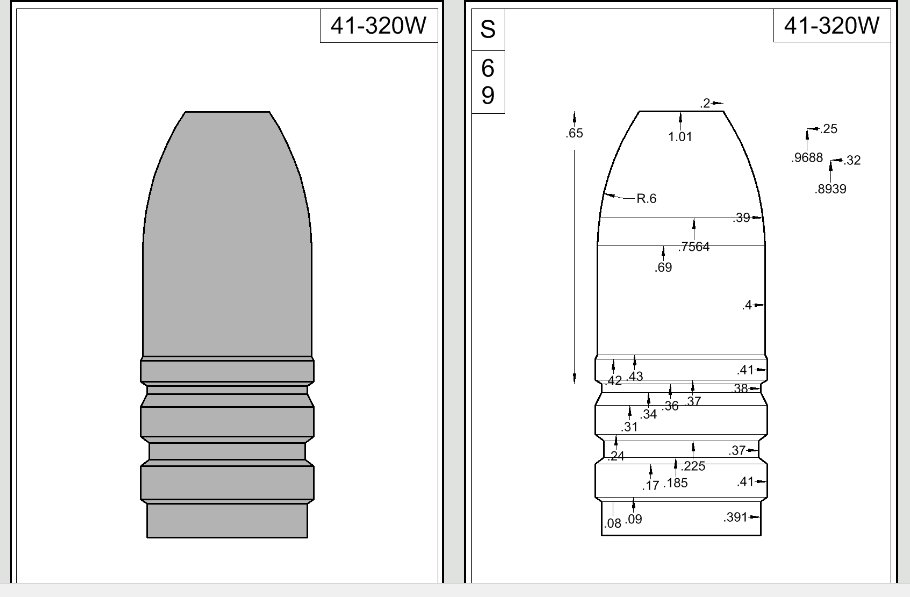

As for the barrel I had got onto one that was a take-off and had been chambered for the a shortened 405 Winchester --the 405 x 2.2. It had been fitted to a Marlin Lever action so needed som work on it. Thr action thread was turned off and a sleeve was machined up and threaded onto it. One downside was that it had two dovetail cuts on the underside and one for the front sight. I had ordered a reamer to lengthen the chamber but had to keep in mind the Lee Enfield magazine length. I decided to cut the chamber to 2.410 and trim 405 Winchester brass to 2.405 and with the cast bullet I intended to use I could load to a COAL of 3 inches. It would also suit a jacketed bullet.

This is the cast bullet ( standard dimensions) but the mould has been ordered to suit the barrel dimensions.

| VonGruff |

| (.400 member) |

| 17/02/15 07:18 PM |

|

|

I started the barrel inlet but can not finish it till the rechamber is done, it gets timed to my action and snugged into place. In the meantime I decided to make a couple of extra tools to help with the channel finish. To date I had been using parts of old barrels as push scrapers but that is not always the best way to do it so I cut a 3/4 inch lengths of the end of the barrel bits, drilled them to 7mm and hardened them

Some long 1/4 in bolts were set for the handles and 3 nuts were ground down so they would be a back nut and unobtrusive for scraping. Three lengths of 7/8 in dowel were drilled, the heads were cut from the bolts and some fins made on the shank to hold them into the handle

A bend on the bolt and the handle tapped into place and I have three sizes of scrapers. They may not look it from the pic but the bends are all the same and the scraper heads are reversible and sharpenable so should do for quite a while.

| VonGruff |

| (.400 member) |

| 17/02/15 07:20 PM |

|

|

To fix - hide the dovetails a piece of steel was filed to shape and tapped into the first one

A bit of cleaning up and it would almost hide with a touch of blue

The centre one was done the same but would be used to position the barrel mounted sling eye. A piece of shotgun barrel was used to make a base for the sling eye

a hole was drilled into the dovetail, the sling screw was cut and a groove made round the stub so when it was all soldered together it would make a good bond.

| VonGruff |

| (.400 member) |

| 17/02/15 07:22 PM |

|

|

Some of the square has been taken from the forestock and this is how it will sit till the reamer gets here about mid march

| stug |

| (.275 member) |

| 17/02/15 07:28 PM |

|

|

WOW!!! Impressive work. You can see why a quality wooden stock costs so much.

| CarlsenHighway |

| (.300 member) |

| 17/02/15 08:13 PM |

|

|

This is what happens when a true enthusiast is also a master craftsman, he can recreate something like this. Fascinating to see it take shape stage by stage.

These rifles are going to be impressive.

| Waidmannsheil |

| (.400 member) |

| 17/02/15 08:15 PM |

|

|

Great job, well done.

Waidmannsheil.

| Norman4 |

| (.300 member) |

| 18/02/15 02:43 AM |

|

|

Excellent write-up with pictures! You make it appear much easier than I know it is. Gives all a lesson on some of the idiosyncracies of the Lee action too. Thank you for taking the time to post all of this up for us to see.

| Caprivi |

| (.375 member) |

| 18/02/15 11:50 AM |

|

|

|

This is a wonderful example of why we love this forum.

Bloody good show.

| Iowa_303s |

| (.400 member) |

| 18/02/15 01:41 PM |

|

|

Excelent post!

I don't know whether you are a great inspiration or a dangerous enabler.

Again, great work and overview of the build process.

| Norman4 |

| (.300 member) |

| 19/02/15 09:57 AM |

|

|

Quote:

Excelent post!

I don't know whether you are a great inspiration or a dangerous enabler.

Again, great work and overview of the build process.

Ha! Yes indeed!

| DarylS |

| (.700 member) |

| 19/02/15 10:42 AM |

|

|

|

Very nice- wow- I admire your tenacity and skill. I've long lost that enthusiasm - at times I wish I still had it -

bravo!

| VonGruff |

| (.400 member) |

| 02/03/15 09:37 AM |

|

|

The barrel for the 375-303 turned up so the forestock could be finish inletted and given some shape. Sitting at 150grtit sandpaper finish for now but I do like the balance and swing this one has.

The 405 Winchester reamer to lengthen my chamber from 2.2 out to 2.41 is still a few weeks away so there is a bit of a stall on progress at the moment.

| VonGruff |

| (.400 member) |

| 08/03/15 12:11 PM |

|

|

After seeing the trigger guard with the waist ground into it on the recent thread I decided I needed that for my 400 so a short spell on the grinder and with some polishing it looks a bit better to my eye, so I did the same for the one on my 303 as well. Slightly less waist on the 400 but it does take away from the solid square look quite nicely.

I had been having trouble sourcing ebony here in NZ which was partially why the grip cap had simply been walnut but a friend had got onto a small block that will do 3 tips so I decided to remove the walnut grip cap and used the last small piece of ebony I had and cut a grip blank that will replace the present walnut one

| VonGruff |

| (.400 member) |

| 08/03/15 02:27 PM |

|

|

With that in mind I sorted through the router bits and by changing the end bearing to a smaller size and being just a bit careful I was able to sit the router in the vise and by holding the cap with a piece of dowel only had it thrown out of my hand a couple of times but goterdid. Will shave the top down when it is installed.

| VonGruff |

| (.400 member) |

| 08/03/15 04:39 PM |

|

|

I was a little concerned about the fingers so for when I do any more of them made a helping tool using a light piece of scrap metal I marked the two holes of my pattern (that I use to pin the cap to the stock with 1/8 in brazing rod) and tapering the end added a pair of pins that would locate on the base of the cap so it could be held securely.

| VonGruff |

| (.400 member) |

| 09/03/15 03:44 PM |

|

|

I had got the 375-303 finished as far as I am going with it so it can be returned to its home base for sights and blue. The blank didn't have a lot of grain definition but the alkanet oil has bought a subtle tone that has made it rather nice

| VonGruff |

| (.400 member) |

| 09/03/15 03:45 PM |

|

|

Having got the new ebony grip cap made for my 400 I had to cut the walnut one off.

It took a little time to file the saw cut back to the stock wood and make it flat for the new cap but once that was done I made new brass dowels and got it epoxied into place.

A trim up of the stock wood with needle files and fine paper had things reconciled again. I had made the new cap a couple of thou smaller so the stockwood could be blended back into the cap dimensions.

Am pleased I decided to change things as I like the contrast of the new cap. The plain caps had been used initially because the original BSA 375x2 1/2 had a grade of finish without a cap but I had wanted to protect the end grain and had done the 400 the same but being able to get the ebony changed my mind before I had gone too far.

| Ash |

| (.400 member) |

| 27/04/15 04:19 PM |

|

|

Enjoying this! How's it coming along?

| VonGruff |

| (.400 member) |

| 28/04/15 07:33 AM |

|

|

Been progress Ash.

After the grip cap was done I added an ebony tip to the forestock

The trigger guard anchor lugs had the edges radiused as that is the part that the inside of the finger rests on. It has a much better feel this way

The dies and a 405 reamer arrived from the US and a box of 405 win brass (thanks Sarg) so I was able to get that side of the project sorted.

I did the arithmetic and cut the case length back to 2.410 and seated a bullet for an OAL of 3.052

| VonGruff |

| (.400 member) |

| 28/04/15 07:43 AM |

|

|

With a case at the 2.410 length, it showed the chamber that had been cut for the 405 x 2 1/4 needed attention and because I had to time the barrel to my action this was not a concern. The barrel (being a take-off) had been sleeved to within a 1/16 of a turn to a friends action before the barrel was sent to me so in short order it was timed to mine and removed for the chamber work

Slow and with plenty of cutting fluid (ok, I used ATF)and with many checks for depth and to clear the sludge from the cutting flutes

Finished

Filing in the extractor groove

Breaking the mouth of the chamber

| VonGruff |

| (.400 member) |

| 28/04/15 08:03 AM |

|

|

The cartridges would not feed from the magazine or hold themselves in it for more than one so that required a little though and a remedy.

A piece from an old vehicle roof rack support made a dandy cartridge follower so I could save to original one unmolested.The follower needed to be narrower at the rear so I made it to exactly the width of the spring. With the turn up at the front and the turn down at the rear it was a perfect fit for the rimmed cartridge

I used some .040 stainless and made up an insert for the mag that would be held down by the spring and shaped the top to make it center feed and after a few trial re-shapes of the feed lips and the spacer folds down the back edge I finally got it to hold and feed

click on this short vid of it feeding. There was one hiccup but I found that I was occasionally running into the feed ramp so I opened the front of the lips a smidgeon to let the nose rise a fraction sooner and it fixed the problem. I didn't take another vid after the fix

[IMG]http://i667.photobucket.com/albums/vv39/VonGruff/405%20Krag%20Enfield/th_Video0001_zpsvtmvhkzm.mp4[/IMG]

| VonGruff |

| (.400 member) |

| 28/04/15 08:43 AM |

|

|

About this time it was apparent I would need a front sight so A Lee Enfield military sight looked like it would do the job with a little work

The part I couldn't do myself was to open up the inside of the band. I don't have a lathe (or a mill) so it was down to the local garage where he has a small lathe and he opened it up for me.

The locating lug recess's were almost completely removed so there was no visible remainder when I tapped it onto the barrel.

I went and fired a few shots and with the aperture sight at the lowest setting where I wanted it to be, the shots hit 22 1/2 inches low at 50 yds. With a 31in sighting radius, I needed to lower the front sight by .3875 and if I filed the ramp down and cut a new dovetail that would have cut through the hole at the top of the band that was there for locating purposes, and would have dramatically weakened the hold on the divetail. This led me to file the ramp down and split it lengthwise deep enough to take a blade I made from a piece of .125 thick steel. (just a square I cut from a piece of 3x2 box steel) The blades for the LE sights are only .05 thick and my eyes can not see them clearly enough as they fuzz up badly but I have found that the thicker blade is a usable sight and I have split more of these blades and fit them over the thin blades on some of my other open sighted rifles.

The sight was over about .785 from the band to the top of the blade as the LE offering and when I got it "sorted" with the new blade so it would print on aim it was down to .306

I did start with plenty of blade height

This will do

| VonGruff |

| (.400 member) |

| 28/04/15 08:52 AM |

|

|

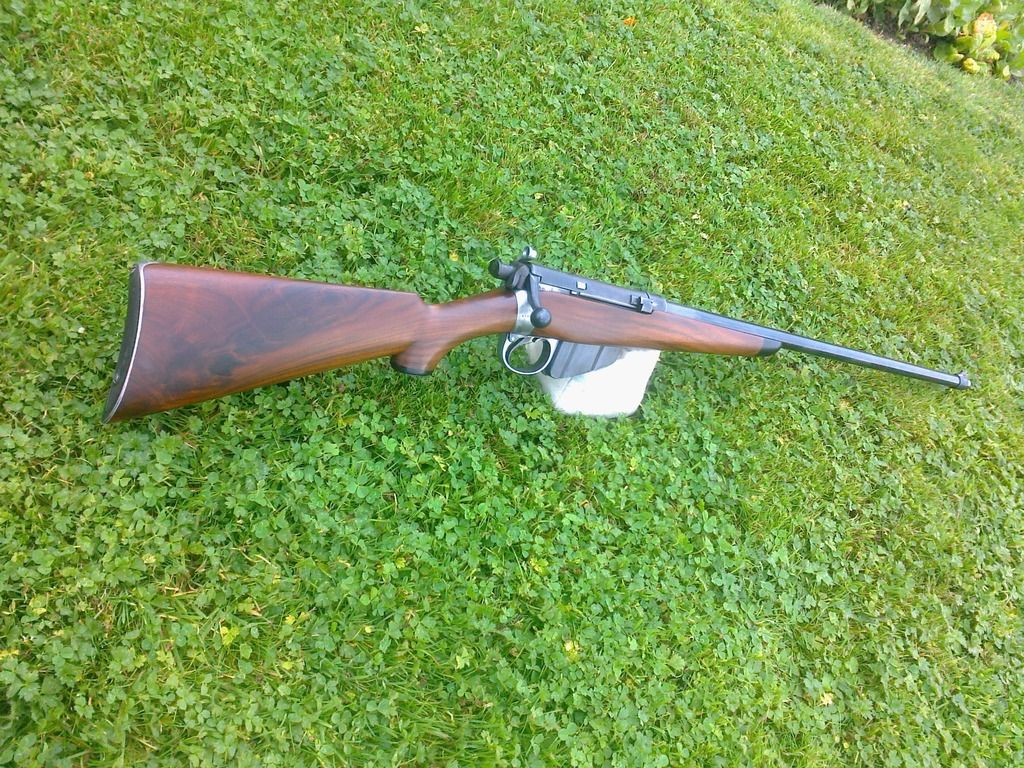

So with most things taken car of and a little cold blue splashed around, the stock was the centre of attention for a couple of weeks and after some alkanet/blo and tung oil I think I can just about call it done.

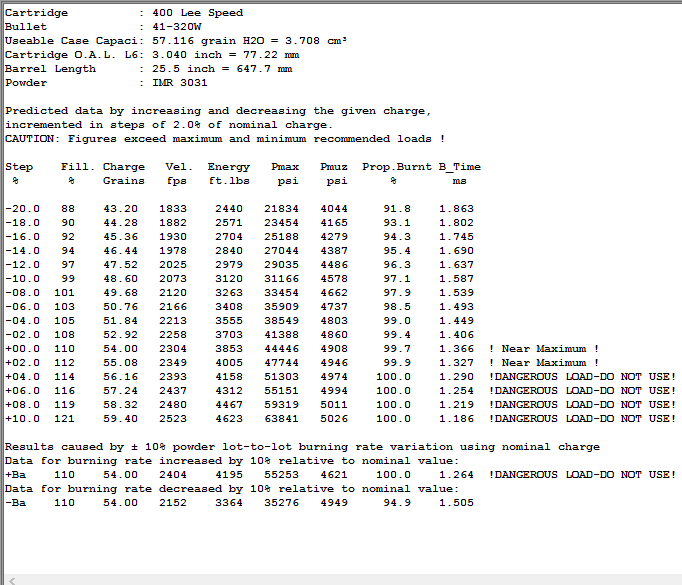

I have only just used a plinking load to date with the 320gn cast bullet over 18gn Blue Dot for about 1450fps to semi regulate the sights but have 3031 set aside to do some serious work-up with as Ql tell me that 2300fps is comfortably attainable

Even the 400gn Woodleigh bullet should get to 2150fps and that is no mean performance, having been recognised as a decent load for --oh about a 100years or so

| VonGruff |

| (.400 member) |

| 28/04/15 08:56 AM |

|

|

I think that paired with the 303 I did a while back and recently refinished I have the means to go most places and be reasonably comfortable with what ever might come across my path.

| CHAPUISARMES |

| (.416 member) |

| 28/04/15 09:04 AM |

|

|

I have been following your thread and all I can say is your a very talented man Von Gruff, well done

| Bidgee |

| (.375 member) |

| 28/04/15 10:48 AM |

|

|

|

|

Dear Von Gruff,

I have followed your thread as well and have thourghly enjoyed the creation of your latest work. Very well done!

Cheers

| VonGruff |

| (.400 member) |

| 28/04/15 11:22 AM |

|

|

Thanks guys. Just an enthusiastic amateur with needs/wants and more time than money.

| Iowa_303s |

| (.400 member) |

| 28/04/15 01:42 PM |

|

|

Well done Von Gruff!

Love the heavy cast bullets. I can't wait to get my son graduated from college and moved to his first real job so I can get back to my 9.3 cast bullet project.

| stug |

| (.275 member) |

| 28/04/15 02:28 PM |

|

|

Beautiful work. I never really new about Lee Speeds until I came across this site. I can see one sitting in firearms cabinet one day.

| DarylS |

| (.700 member) |

| 29/04/15 01:03 AM |

|

|

|

Nicely done.

| 93x64mm |

| (.416 member) |

| 29/04/15 06:18 AM |

|

|

I reckon some deer or goats will be in for a rude shock soon ol' mate

Will be good to see how she goes in the field

As always keep up the good work

cheers

93x64mm

| Sarg |

| (.400 member) |

| 29/04/15 06:41 AM |

|

|

Two projects in a row used the cases I helped with, I'm honoured !

Glade I could contribute to this project VonGruff & see the action & cases put to good use, funny how you modified the trigger guard & I spend hours rebuilding one of those Lee Speeds that some one had done that to, I wish I had left it now .

Thank you also for doing your magic on my old girls to, just need to get my rebored .375 & .40 barrels from the US & get my others done !

Great work & write up thank you !

| lancaster |

| (.470 member) |

| 01/05/15 02:22 PM |

|

|

very nice rifle in the end, excellent

| Pretorius |

| (.224 member) |

| 22/06/15 08:50 AM |

|

|

Yes, very nice indeed, but.....the screws holding the peep sight don't match in the photo, did you fix it? Sorry , I can be a tit about these little things. Perfect work tho, all you need now is a pith helmet and steamer to africa.

Mr P

| Viking338 |

| (.333 member) |

| 22/06/15 10:48 AM |

|

|

Beautiful work mate, it's a credit to your talent. I have thoroughly enjoyed keeping up with it. Now you can go enjoy!!!

| Old_Glass |

| (.300 member) |

| 22/06/15 02:57 PM |

|

|

If ebony is hard to find from suppliers, you can usually pick up some of those grotesque African carved busts etc. at flea markets or "junque" shops. There is often a good chunk of wood left in the heads. Every time I see those things I lament over the fine, rare and slow-growing wood that is wasted in making them.

I'm sure you can learn to chequer too! ;-)

If you want a peep sight, I would consider mounting one on the cocking piece.

The rifles look very nice indeed. A silk purse from a pig's ear.

| BillG500 |

| (.300 member) |

| 22/06/15 06:29 PM |

|

|

I've done the same thing and got some ebony for a fore end from the markets, talked the price down because the elephant had a chipped toe and then went home and cut it up.

I saw a video of a Lee Speed with a peep on the cocking piece. The peep was missing but the dovetailed base was still there, I think that design would be the go.

| gwh |

| (.333 member) |

| 22/06/15 09:49 PM |

|

|

Very nice!

| VonGruff |

| (.400 member) |

| 23/06/15 11:12 AM |

|

|

Quote:

Yes, very nice indeed, but.....the screws holding the peep sight don't match in the photo, did you fix it? Sorry , I can be a tit about these little things. Perfect work tho, all you need now is a pith helmet and steamer to africa.

Mr P

The screws were only temporary at the time. I have had lever headed screws made and when I have the loads sorted (after the weather gets past winter)I will finish timing and shaping them.

I have seen (and greatly admired) the bolt mounted aperture on the Lee Speed as I have done the stock work on a couple belonging to a friend with them mounted and I have one on my 7x57 but that was acquired when I was still in the work force and could afford such things. These sights were of my own design and from materials I had "under the bench" so only cost me some time at the bench. They have proved themselves to be very effective and will do the job.

| VonGruff |

| (.400 member) |

| 23/06/15 11:20 AM |

|

|

As far as the ebony goes, there are no junk shops in the small village where I live and trips to the city are for the minimum time and for necessities only. I have managed to get a little from a good friend though, so the next couple of projects have the tip and cap sitting in wait. I have also been the recipient of some buffalo horn from a friend in SA, so have a couple of tips and a few caps there if I want to use them instead although they will be kept for a special project or two.

| DarylS |

| (.700 member) |

| 23/06/15 12:01 PM |

|

|

|

Quote:Quote:

Yes, very nice indeed, but.....the screws holding the peep sight don't match in the photo, did you fix it? Sorry , I can be a tit about these little things. Perfect work tho, all you need now is a pith helmet and steamer to africa.

Mr P

The screws were only temporary at the time. I have had lever headed screws made and when I have the loads sorted (after the weather gets past winter)I will finish timing and shaping them.

I have seen (and greatly admired) the bolt mounted aperture on the Lee Speed as I have done the stock work on a couple belonging to a friend with them mounted and I have only on my 7x57 but that was acquired when I was still in the work force and could afford such things. These sights were of my own design and from materials I had "under the bench" so only cost me some time at the bench. They have proved themselves to be very effective and will do the job.

Very nice indeed - well done VonGruff, interesting, inovative and effective, I'll bet. Perhaps you should market them? Might sell a few right here.

| VonGruff |

| (.400 member) |

| 23/06/15 12:50 PM |

|

|

Thanks Darryl. The one downside to ths design is that if I want to remove the boltI need to loosen off the lever a half turn and lift the sight so the bolt can come back but that is a small thing as I have it so the general 100 yd setting is when the adjustment slot stops at the screw shank so when the bolt goes back in the sight comes down to its lowest setting and the levers tightened a half turn. While this may not be convenient for some I don't see the need for any further adjustment although there is room to make it to 1000yds. Set for a couple of inches high at 100, it will do to about 200 and that is as far as I will shoot open sighted anyway.

The time it takes to make and regulate is way more that would make a saleable project unfortunately.

| BillG500 |

| (.300 member) |

| 23/06/15 02:43 PM |

|

|

VG

You wouldn't happen to have a photo of the cocking piece aperture sight you could post?

I've only seen what the base looks like.

| VonGruff |

| (.400 member) |

| 23/06/15 05:19 PM |

|

|

This is one on a restock I did a while back. I expect to be getting the rifle back soon to fill the lobbing sight recess and reshape the wrist.

a genuine Lee Speed with bolt aperture and a couple of restocks I did.

| 93x64mm |

| (.416 member) |

| 23/06/15 05:29 PM |

|

|

Awesome work VG!

The cocking piece peep, where did you dig that up from?

Is it off an original Lee-Speed?

93x64mm

| VonGruff |

| (.400 member) |

| 23/06/15 05:32 PM |

|

|

One is adapted from a Lyman tang sight I think it was and had a fabricated base and I am not sure what the other one came from