| Ron_Vella |

| (.333 member) |

| 04/07/11 12:15 PM |

|

|

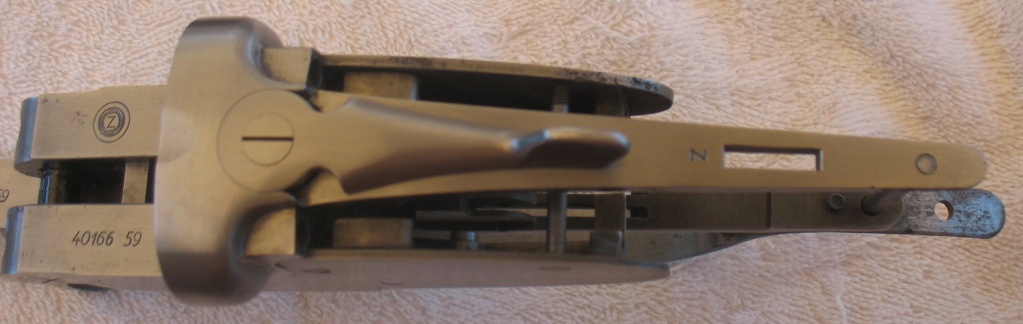

After a search of months, I finally found a BRNO Model ZP-47 in 16 gauge, as a host gun for my new double rifle build. The gun had been badly neglected, including a lot of pitting to most all of the steel surfaces. This has necessitated the wearing out of a lot of stones, emery paper, and a few finger tips. Here are a few shots of where I am with it.

I have re-finished the stocks, stained them English red, re-cut the checkering, and added a 1 1/2" Silvers-style pad. There are about 20 coats of TruOil on it now. It needs to hang for about another month to ensure that the oil is good and hard, then a final rub-out with linseed oil and pumice.

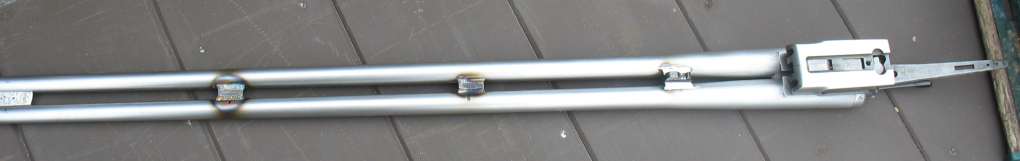

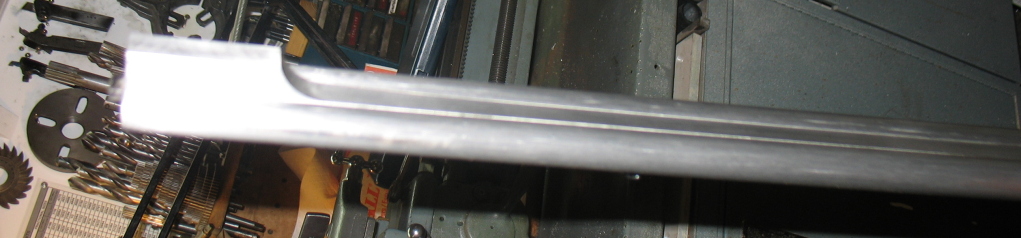

Here are the stubs of the barrels, fresh off the milling machine. The bores have been machined out to 0.780", then threaded 13/16-32 TPI.

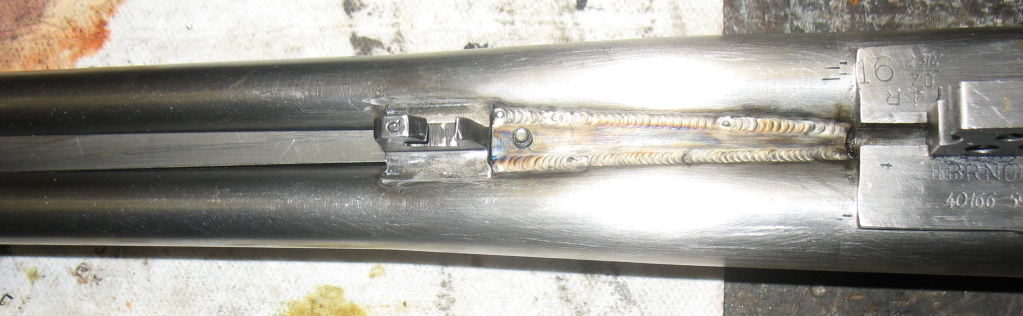

Here is the new extractor plate and the new extractor rod, fitted into place and ready to be micro-TIG welded together, then faced off and stoned to final dimension.

Here are three shots of the action, from various angles, showing the result of about 30 hours of stoning and polishing.

More to come as this project goes along. Unfortunately, due to a blocked sewer, our basement flooded on Friday night. So the place is full of insurance adjusters, cleaners, and contractors, and my shop will be unuseable for a bit!

By the way, the 12 gauge BRNO ZP-49, that I built my .450 #2 NE on, is serial-numbered 40165, built in 1963. If you look at the photos above, you'll note that the serial number of this gun is 40166, built in 1959.What are the odds of buying two different guns, in two different gauges, from two different sources, about 10 years apart, and having them consecutively serial numbered? I wonder if I'll be entitled to call them a "true pair"?

| CHAPUISARMES |

| (.416 member) |

| 04/07/11 12:29 PM |

|

|

That is coming on nicely, good luck with it...

.

| AkMike |

| (.416 member) |

| 04/07/11 04:55 PM |

|

|

Once again this shows that you are indeed a craftsman! Wonderful.

I can come fairly close to your serial number situation. My 500/450 3 1/4" Hollis was built in 1906. Another gent here in town came up with another Hollis 500/450 3 1/4" only 3 numbers away. What's the odds that over 100 yrs later on they'd show up together again in the same rack at the range in this part of the world?

| kamilaroi |

| (.400 member) |

| 04/07/11 06:22 PM |

|

|

Interesting inasmuch as I have 2 Westley Richards 1897 patent falling blocks numbered in the 3535x range. On the final digit a single number divides them.

| DarylS |

| (.700 member) |

| 05/07/11 12:54 AM |

|

|

|

Nice work, Ron - as usual. I don't 'get' the larger sequential serial # being built 4 years before the smaller one.

The true oil should finish to a nice 'perfect' piano finish. A local gun maker showed me a similar technique - makes for an interesting 'piece'. I used a his method to duplicate the finished plastic appearing surface of a new Belgium Browning for a friend.

| Ron_Vella |

| (.333 member) |

| 05/07/11 06:40 AM |

|

|

Daryl,

I believe that they probably forged and machined a large number of receivers at one time, stamped them with serial numbers, then drew them from inventory as needed, in no special order, it would appear.

| Ron_Vella |

| (.333 member) |

| 07/07/11 11:02 AM |

|

|

Yesterday I went to the micro-welder and had him weld the extractor plate to the extractor rod. On the way home I stopped at my machinist friend's home and had him mill off the plate to within about 1 1/2 thou of complete. I also had him indicate on the bores to centre each of them and then bore through the plate for the cartridges, but 50 thou under-size.Today I spent a few hours smoking in, draw-filing, and stoning until the barrel assembly just closes snugly on the action. Here are a few pics:

| DarylS |

| (.700 member) |

| 08/07/11 01:59 AM |

|

|

|

Quote:

Daryl,

I believe that they probably forged and machined a large number of receivers at one time, stamped them with serial numbers, then drew them from inventory as needed, in no special order, it would appear.

Sounds as if that is the way of it - strange, though - to me.

| bwanabobftw |

| (.375 member) |

| 08/07/11 03:47 AM |

|

|

Nice work.

Robert

| Ron_Vella |

| (.333 member) |

| 31/01/12 01:49 PM |

|

|

After months of waiting for them, I finally got my two barrels last week. Yesterday I was able to get back to work on this project. Here are a few photos of what I've done in these two days:

Here they are, a pair of McGowan, 26" barrels, in the Shilen #2 profile. Rate of twist is 1:12.

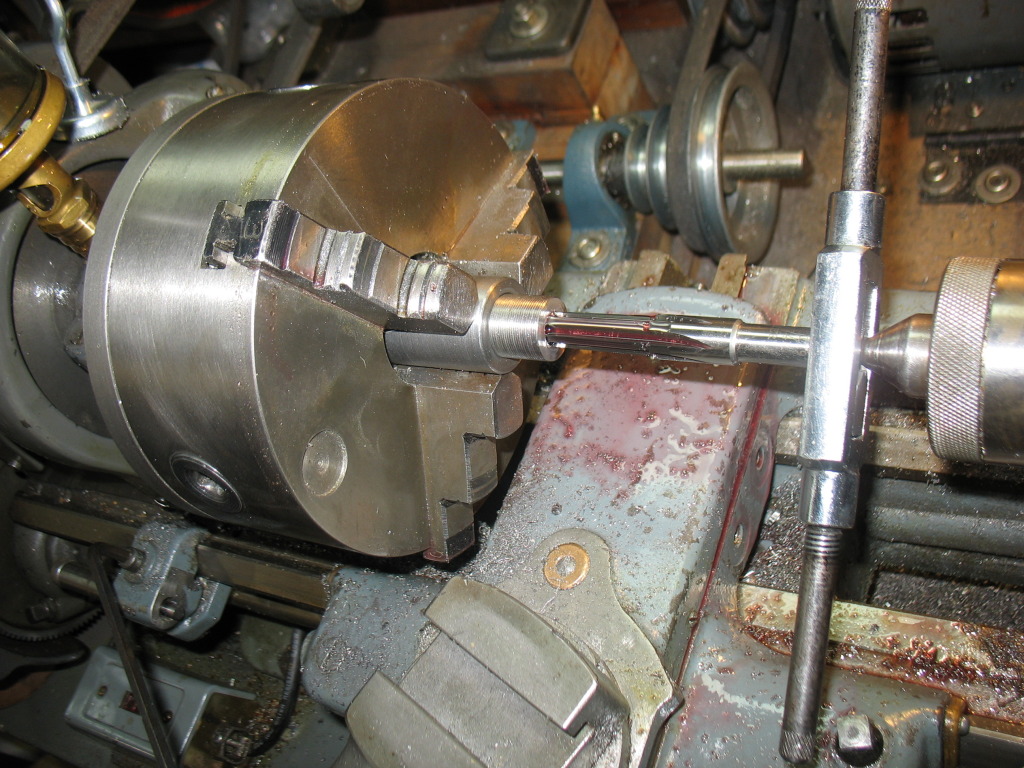

Here I'm turning the shank end to the OD of the front end of my monoblock.

Threading the barrel shank, in this case, 13/16"-32tpi.

Reaming one of the chambers. I read elsewhere of a formula for lubricant for this job, consisting of 50% Ford type F automatic transmission fluid, and 50 % SAE 10 motor oil. This is the first time that I've used it and it's great. After cutting both of these chambers, with only a finishing reamer, I slit my finger open on one of the flutes while wiping the reamer clean. That's still SHARP.

Here we are with the first barrel screwed up tight into the monoblock.

And here's the second.

Here are two dummy cartridges in the chambers. Barrels lock up with lever still well to left of centre, but things will wear in as we go along.

More to follow, with better photos from a better camera.

| Ron_Vella |

| (.333 member) |

| 31/01/12 02:09 PM |

|

|

I forgot to mention, while wandering the aisles of a gun show, about a month ago, I found a twin to this gun. It's another BRNO ZP-49, in 16 gauge as well, and in virtually pristine condition. When I'm finished this project, I'll have a pair, rifle and shotgun, in one fitted travel case.

| AkMike |

| (.416 member) |

| 31/01/12 02:17 PM |

|

|

The serial number wouldn't happen to fall in with the others would it?

| Ron_Vella |

| (.333 member) |

| 31/01/12 11:15 PM |

|

|

No, it's nowhere near them , Mike. If it did, I'd be playing the lottery tonight!

| AkMike |

| (.416 member) |

| 01/02/12 05:52 AM |

|

|

That's exactly what I was going to suggest Ron!

| 500Nitro |

| (.450 member) |

| 01/02/12 07:28 AM |

|

|

Quote:

The serial number wouldn't happen to fall in with the others would it?

I had that happen with a Holland Shotgun once, was on the phone to, as it happens a firearms dealer over here in Aus. Found out in general conversation he collected English guns, we discussed what we had.

his ears pricked up at the mention of a Holland, I said it was No 1 or 2 of a pair, he asked what the serial number was and hey presto, I had the other.

His next words were "and the price just went up $5000" to which I replied, "No, $10,000".

He was a happy chap.

.

| DarylS |

| (.700 member) |

| 02/02/12 01:35 AM |

|

|

|

Ron - why such a fast thread. My guess is strong but less material removal, tighter fit in the threads themselves with less actual gap measurement in individual threads?

That makes sense. Nice work, btw. I've just used rapid tap for threading, worked fine for me, by hand or on the lathe.

Will have to try the tranny fluid and motor oil, though, cheaper.

| Ron_Vella |

| (.333 member) |

| 02/02/12 08:43 AM |

|

|

Daryl,

I like 32tpi because it involves removal of less wetal from the monoblock, ie: major thread daiameter minus minor thread diameter.

| Ron_Vella |

| (.333 member) |

| 02/02/12 01:32 PM |

|

|

I spent quite a bit of time today, draw-filing and then stoning the monoblock/barrel juncture in order to continue the taper of the monoblock in a smooth flow into the barrels and to hide the seam between the two. As you'll see in the photo below, that seam is almost invisible, and after final polishing and rust bluing, will be impossible to see unless held just so in bright sunlight.

| DBLGN |

| (.224 member) |

| 10/02/12 04:29 AM |

|

|

Nice work Ron. Always fun to watch someone else's work progress. I recently built a .450-3 1/4 on one of these BRNO 12 bore actions - I was very impressed with them. I am sure this has been mentioned other places, but they have chopper lump barrels which I really like. The one I used for the above gun, had ejectors and interrupting sears, as well.

Ellis

| Ron_Vella |

| (.333 member) |

| 10/02/12 10:36 AM |

|

|

I built a .450 #2 NE on a BRNO ZP-49 a few years ago. There are at least 1000 full-house loads through it and it is still as tight and on-the-face as the day that I finished it.

| Ron_Vella |

| (.333 member) |

| 23/02/12 12:57 PM |

|

|

Hopefully what I'm about to explain may be of value to a few other builders. A couple of weeks ago I was at the point where I was ready to solder these barrels into the mono-block. Before I did, I decided to put all of the components, including scope and rings, on an accurate scale, to determine aproximately what the finished rifle was going to weigh. I was astounded to find that it was going to be just a couple of ounces shy of 11 pounds, a fine weight for a .45 calibre dangerous game rifle, but far too heavy for a 9.3 x 74R. There are a number of areas where I'm going to shave some weight, but the most obvious was the barrels. When I set them up in my lathe, between centres, there was far too much chatter to get a good finish.

I took the barrels to a local precision grinding company and asked them to remove .025" from the radius for a total reduction in diameter of .050". They set the barrels between centres and ground .001" per pass under a heavy flow of coolant along the entire straight taper of the barrels. They were even able to blend the rear end of the grind very nicely into the radius at the front end of the breech reinforce. The total charge for this service was $80.00, which I think is extremely reasonable.

The best news is that this grind resulted in a weight reduction of 10 1/4 ounces for the two barrels. That's a big reduction in just one component. Something to bear in mind if you have a similar problem. And by the way, the resultant finish is like a mirror, and the finished diameter of the two muzzles doesn't differ by .0001"!

| AkMike |

| (.416 member) |

| 23/02/12 03:52 PM |

|

|

That's quite a weight savings with only a .050 reduction.

What's the barrel thickness at the muzzle now?

| Ron_Vella |

| (.333 member) |

| 24/02/12 05:16 AM |

|

|

Mike,

The OD at the muzzles is now 0.526" and the wall thickness, in the centre of the grooves, is now 0.081", plenty thick enough for the pressure out at that end. One thing that I learned years ago from Tony "Marrakai" is to keep the muzzles light and the weight at the rear of the barrels, if you want to end up with that lovely "between-the-hands" feel of the classic British double rifles. If you don't do this, you end up with a muzzle-heavy rifle that swings like a sledgehammer.

Best,

Ron.

| DarylS |

| (.700 member) |

| 24/02/12 06:19 AM |

|

|

|

Thanks Ron - quite a trip and learning experience for me. I truely appreciate this open 'tutorial' style of thread.

| AkMike |

| (.416 member) |

| 24/02/12 06:32 AM |

|

|

Just for a FYI if you're interested...

My 9.3X74 Chapuis measures .520

My Orgris (Ferlach)9.3X72 is .480 But this has a .363 bore.

Another one is .510 with the same 363 bore.

You're right in the ball park!

| MaxGera |

| (.275 member) |

| 24/02/12 12:00 PM |

|

|

|

Hi Ron,

Great job blending the barrels to the monoblock.

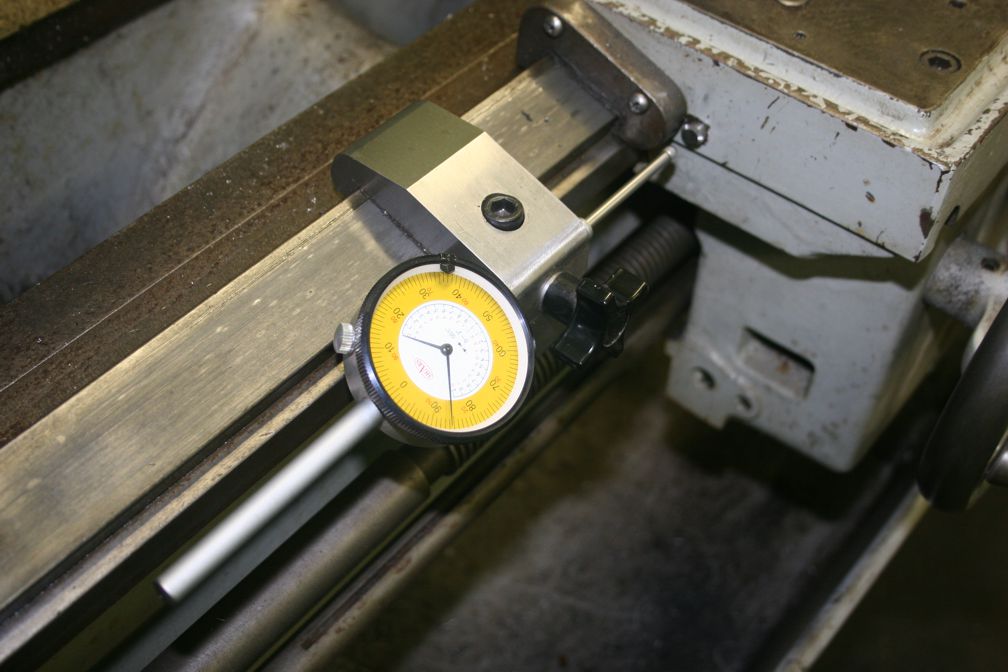

I use a totally different set-up for chambering barrels. It allows me to finish chamber to the correct headspace within .001" the first time every time.

Mounting the reamer to the saddle allows a better feel for the cutting and I can center the reamer holder much easier than the tailstock.

All I do, is get the reamer in by eye until about 1/8" from finish. Then I set the indicator to Zero.

Next, I measure with the headspace gage to see how much more I need. Then I simply go in until I get the correct reading on the indicator. Works every time.

| Ron_Vella |

| (.333 member) |

| 24/02/12 01:05 PM |

|

|

That's hugely useful info, Mike. Thanks a bunch!

| AkMike |

| (.416 member) |

| 24/02/12 04:48 PM |

|

|

I wondered if you'd done and comparisons and hoped this may help.

One note though. the one with the .480 has sculpted barrels that are different/unique from any I've seen before. Even at the chamber area. PM me you email and I'll send pics of this tiny beast.

| chipmaker |

| (.224 member) |

| 04/03/12 03:39 PM |

|

|

Max

Could you describe how you center the reamer holder in the lathe saddle?

Otto

| Ron_Vella |

| (.333 member) |

| 30/03/12 03:34 AM |

|

|

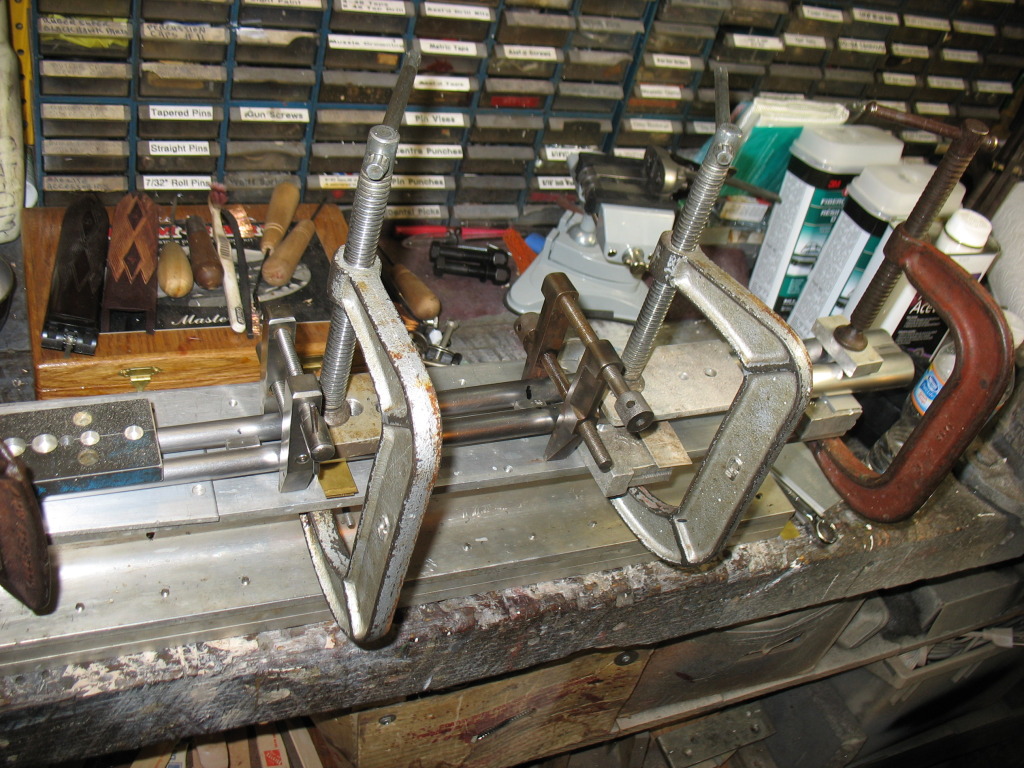

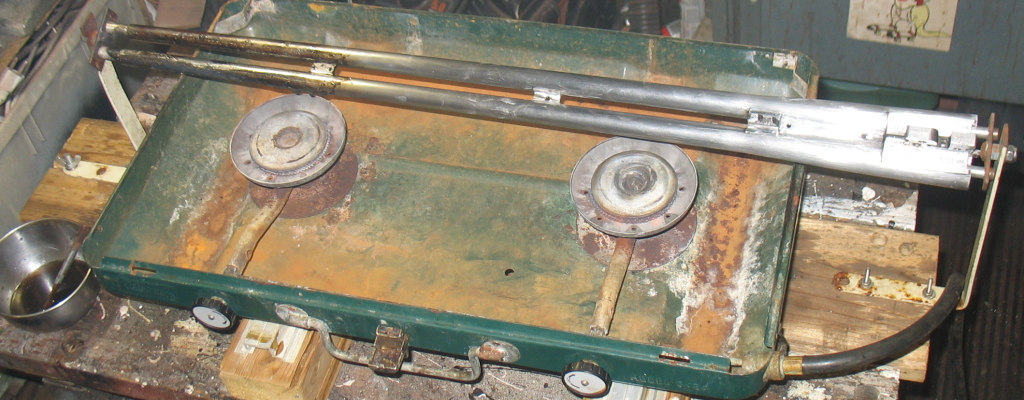

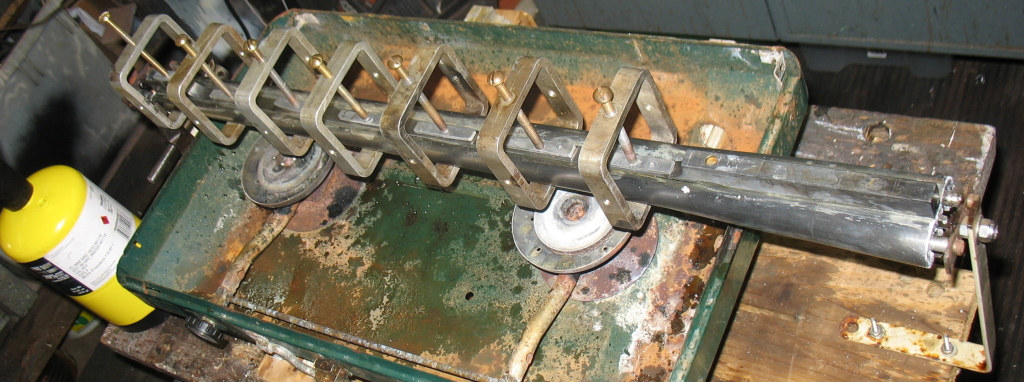

I've had to put this job aside for the last few months, due to a couple of major "honey-do" projects which are now pretty much completed. I spent a few hours machining two spacers to be welded between the barrels. Here is a photo of the barrel assembly, spacers in place, and everything carefully clamped to a rigid section of aluminum I-beam, ready to go to the TIG welder.

| Ron_Vella |

| (.333 member) |

| 30/03/12 05:06 AM |

|

|

Here we are back from the welder.

Photo #1 show barrels with the two spacers and the fore end hanger welded into place. I've spent a bit of time cleaning up the weld around the hanger but still have to stone the area.

Photo #2 is a close-up view of one of the welded--in spacers.

Photo #3 shows the fore arm assembly fitted to the hanger, after some careful filing and stoning of the notch so that it juuust snaps into place

More to come.

| Sarg |

| (.400 member) |

| 30/03/12 09:06 AM |

|

|

Awesome job, great to see it coming along, I think you are getting even better, looks nicer than a lot of factory jobs !

Thank you for sharing !

| buckbrush |

| (.300 member) |

| 05/04/12 06:50 AM |

|

|

Ron I have found using a live center made by Concentric tool works very well for turning down barrels with no chatter. I will see if I can find a reference picture.

http://www.riten.com/products/live-centers/spring-loaded-concentric-greber-live-centers.html

| Ron_Vella |

| (.333 member) |

| 02/07/12 10:23 AM |

|

|

I've been away from this project for too long due to a number of "honey-do" jobs and a fishing trip to Guatemala. I got back at it this past week and got a bit accomplished. I took the barrels to the micro-welder and had him fill in the seam in the rear face between the barrels and the mono-block. After some careful filing, smoking-in. and stoning, the barrels are back on the face and there is no longer any seam visible. I then finished cutting the chambers that last few thou and have good tight headspace.Here are two photos of that work:

I also spent quite a few hours smoking-in and filing the top rib until it fits perfectly on the barrels. I wish I had a dollar for every time that I screwed on and then un-screwed that rib this week past! Here are two photos of that work:

I'm now ready to pre-tin the top and bottom ribs and the barrels with Hi-Force solder and then do final assembly, hopefully by the end of this coming week. More photos in a few days.

| Igorrock |

| (.400 member) |

| 02/07/12 04:43 PM |

|

|

Quote:OK, I´m just pondering if you will shoot trap with yours double...

I'm now ready to pre-tin the top and bottom ribs

Looks very good !

| Birdhunter50 |

| (.375 member) |

| 07/07/12 09:12 AM |

|

|

Ron,

A friend of mine and I have been following this build and we wanted to ask you a question about something that we can't figure out. I know you had the barrels clamped down and spaced out on an Aluminum I beam, but how can you have that many spacers welded in place before you start to regulate the gun? It looks to me like all of them except the front spacer are welded permanently together. Do you get enough adjustment between the front and the next spacer to get it regulated?

Just wondering and couldn't figure it out. I really like this build and I think you will be happy with this caliber. Bob

| Ron_Vella |

| (.333 member) |

| 07/07/12 10:56 AM |

|

|

Bob,

All of the spacers ARE welded into place, except for the one at the muzzle. However, I do a lot of measuring and layout work, before I machine those spacers, calculated to give me about .002" /.003" of convergence, in the last 6 inches. That is easy to regulate with the tapered wedge between the muzzles, at least it has been so far. I hope that I don't end up eating those words on this build. I'm just heading down to my shop to do the final carding on all of the reamaining small parts,ie: safety slide, firing pin bushings, screws, etc. Tomorrow morning I'm starting to blue the action.

| 4al2 |

| (.224 member) |

| 07/07/12 12:05 PM |

|

|

Where can we find a Aluminum I beam? also what size clamps? i to is following this project.

| Ron_Vella |

| (.333 member) |

| 11/07/12 09:05 AM |

|

|

When I bought this BRNO, it was covered with rust, some of which was pretty deep pits. It was not what I would have chosen but was the ONLY 16 gauge that I was able to find, after a year of searching. Of course, that darned Irishman Murphy came into play and I found another, in almost pristine condition, after I'd already cut up this one and was well along with the conversion. Now I'm going to have a cased pair, rifle AND shotgun, when I'm finished.

At any rate, after many hours of draw filing and stoning, I made "a silk purse out of a sow's ear".

Sunday night I finished the last carding on the action, let it sit in water-displacing oil for 24 hours, and yesterday spent a few hours putting all of the "bits', as the Brits say, back together. Here are a few photos of the finished product.

Now on to tinning the barrels and ribs and assembling them.

| Ron_Vella |

| (.333 member) |

| 27/07/12 03:30 AM |

|

|

Rather than use a very thin filler rib behind the forend hanger, I filed one up out of stock that was about .100" thick. Yesterday I took it to the "welding magician" and had him TIG it into place. Then I drove over to my tool and die maker friend's house and we set it up in the Bridgeport mill in his garage. We were then able to drill, counterbore, and tap near the front of the quarter rib, for an 8-40 screw, which fastens into the filler rib. This gives me two hold-down screws, the other goes into the original top rib extension. The rear screw will be hidden under the rear scope base. The front screw will be hidden under the rear express sight base. I find that doing the job this way really simplifies the job of soldering the ribs on. Everything is "dead-nuts" square and true and it's impossible for the assembly to shift during the soldering process. Here are a couple of photos showing the "rough-in":

Today I spent a couple of hours with a small grinding head in the Dremel tool, then with progessively finer machinists' stones, polishing down the welds, while the area was flooded with Varsol. Then I drilled and tapped a 6-48 drain hole and installed a plug screw. Here are a couple of photos of where I'm at now:

More to come.

| Ron_Vella |

| (.333 member) |

| 29/07/12 08:10 AM |

|

|

Today I got started on final assembly. In the first photo I've finished pre-tinning the top and bottom ribs with Hi-Force 44 solder and acid flux and am just starting to pre-tin the barrels.

Once that was finished, and everything had cooled down, I took the three pieces to the laundry tubs and scrubbed them well with HOT water and a strong cleaner. This is absolutely necessary in order to get rid of the acid flux before final assembly. Otherwise. you'll have the acid causing rust in all of those hidden places.I then laid them in front of an old hair dryer, set on high, and went to watch the Olympics for half an hour while everything got good and hot and dried all the residual water. Then I painted all of the mating surfaces with a liquid ROSIN flux and clamped it all together. The next two photos show things set up in my Rube-Goldberg jig, Coleman stove in place, and ready for heat and solder.

| Ron_Vella |

| (.333 member) |

| 01/08/12 12:30 PM |

|

|

I spent all day yesterday and a couple of hours this morning, scraping and stoning all of the burned flux and excess solder from the barrels. Then I took them to my tool and die maker friend's house where we set them up in the Bridgeport mill and machined the front sight ramp and the quarter rib down to their final height. Below are 4 photos of where things stand now.

Below is a shot of the barrels fitted onto the action. Tomorrow I'll take the gun to the range and put a half a dozen proof loads through it. Then it's time to cut the mortises and dovetails for the scope bases, front and rear sights, and the grooves in the front ramp to hold the hood. Still a ton of polishing to do but that will wait until after the regulation is complete.

| FrankFarmer |

| (.300 member) |

| 09/08/12 02:40 AM |

|

|

Ron, your work is fab! I want one.

| Ron_Vella |

| (.333 member) |

| 09/08/12 10:49 AM |

|

|

How about I build you one and you can pay me for it with your Westley Richards/Farquarson .600 Nitro express? After finally getting the oportunity to shoot it, at my third annual Dangerous Game Shoot, I've suddenly developed a lust for one!

| Ron_Vella |

| (.333 member) |

| 29/08/12 02:08 AM |

|

|

I've had a bit of a delay in this job. I found that the finished gun was going to come in at over 10 pounds, too heavy. I unsoldered and removed the top rib. Then we set it up in the mill and milled out a 3/8" wide slot in the underside of the quarter rib and the front sight ramp. Then we milled the mortises for the scope bases, the dovetails for the front and rear sights, and the grooves for the front sight hood. Then of course I've had to re-solder the ramp and scrape and stone all of the excess solder and flux away. The photos below show the gun with scope bases, sights, and hood installed and the top of the quarter rib and the front sight ramp matted with a 40 LPI checkering file. The finished weight is now 9 lbs 3 oz. Now I'm ready to start regulating her.

| Igorrock |

| (.400 member) |

| 30/08/12 06:12 AM |

|

|

Looks still very good but why quarter rib and the front sight ramp are so high ?

| Ron_Vella |

| (.333 member) |

| 30/08/12 08:09 AM |

|

|

For two reasons,

First; If the quarter rib had been machined any lower, the release levers for the QRW scope mounts would hit the barrel, making removal much too slow.

Second; I am 6'10"(208cm) tall. The higher rib is MUCH quicker for me to use. When I throw this rifle to my shoulder, eyes closed, then open my eyes, I'm looking right through the scope and dead on target. It's about practicality for me, rather than looks!

| Igorrock |

| (.400 member) |

| 30/08/12 03:27 PM |

|

|

Quote:Good reasons !

It's about practicality for me, rather than looks!

| Ron_Vella |

| (.333 member) |

| 10/09/12 01:12 AM |

|

|

About a week ago, I received a pair of Leupold, matte black, medium height, QRW rings. I have since altered the locking levers so that they clear the tops of the barrels, rust-blued them, and have everything installed and ready for regulation. The first two photos show the rifle wearing its scope, which is a Leupold Vari-X III, 1.75x-5x, matte black finish, heavy duplex reticle.

The third photo shows a comparison between a factory-original locking lever and one which I have altered by hot-forging, filing all contours smooth and round, polishing with stones, and rust bluing. They now look better, are a lot easier on the thumb and fingers with their rounded edges, and they clear the barrels without having to pull them out every 360 degrees. I can now crank these levers undone and remove the scope in just a few seconds. This is the only system that I've been able to come up with, short of very expensive claw mounts, which is fast, secure, returns to zero, and does not leave unsightly levers on the rifle when the scope is removed.

| Northman |

| (.275 member) |

| 28/10/12 11:31 PM |

|

|

What about Talley mounts machined into the 1/4 rib?

Looks really nice on the Hang single shot rifles.

| Ron_Vella |

| (.333 member) |

| 17/03/13 11:08 AM |

|

|

This job is close to being finished. All it requires is a bit of fine-tuning of the regulation and then final polishing and a rust blue. unfortunately, the last few months have been so darned cold and miserable that I decided to wait for warmer weather before sitting at the range and trying to shoot carefully over a Chrony while keeping careful records. I guess I'm getting soft in my old age.

To keep busy, I've started another build, this one a 6.5x57 Rimmed. I've finished turning, polishing, and chambering the barrels and am waiting on a throating reamer from Dave Manson to accomodate Nosler 140 grain Partitions, seated well out in the case. After searching for many months, last week I found a Zabala .410 bore in like-new condition for a host gun. More to come on this project.

One thing that I HAVE managed to get accomplished on the 9.3x74R job is to put together a case to hold both the rifle and the shotgun. I want a case with the nice looks and practicality of an English-fitted one, but one that is bullet-proof for travelling by air. I was fortunate to buy one of Cabela's heavy-duty aluminum cases, just before they discontinued them. I did away with the dense, grey foam that they come with, and English fitted the case in red felt. I'm very pleased with the results as I personally think that it looks good, is practical, and I could drive over the sealed case with my Yukon and not hurt a thing. Here are a couple of photos to show how it turned out:

| Matabele |

| (.300 member) |

| 18/03/13 03:23 AM |

|

|

Case looks great Ron, very functional and attractive!

| Ron_Vella |

| (.333 member) |

| 18/03/13 05:03 AM |

|

|

Matabele,

Thanks very much for the kind words. As info, I hunted Zimbabwe last September with Wayne Diedreksen of Jimba Safaris. We were based in the fantastic Sijaria Camp on the south shore of Lake Kariba. I was fortunate enough to take Buffalo, Sable, Klipspringer, and a crackerjack of a Chobe Bushbuck, all with the .450 #2 NE double that I built about 10 years ago. It doesn't get much better than that! Hope to be able to return to your country soon as my finances recover.

Best,

Ron.

| transvaal |

| (.300 member) |

| 18/03/13 05:35 AM |

|

|

Ron;

I like you double case very much and it looks strong enough to withstand the ground crew efforts at Jo-burg airport.

We do not see many of the BRNO ZP49 shotguns down here in the South and I continue to search for one. However, I have a question about the surface hardness of the BRNO action and sideplates. Are the action and sideplates soft enough to allow engraving without having to anneal them? What I have read about them leads me to believe that they are quite hard and it would take a "Carbalt" graver to engrave them (verses a high speed steel with 8% or so of cobalt added). Question because I am an amateur engraver as well as amateur rifle maker.

Regards;

Transvaal aka Steve

| Ron_Vella |

| (.333 member) |

| 18/03/13 12:40 PM |

|

|

Transvaal,

The BRNO guns are made from what the Czechs called Poldi Elektro Steel which I assume was made in an electric reduction furnace. It is of very high quality, strong, and in my experience is fairly resistant to corrosion though certainly not stainless. The guns that I have worked with were not surface-hardened and I would think could be cut with a regular high speed steel graver. About 10 years ago I built myself a double rifle in calibre .450 #2 Nitro Express on a BRNO ZP-49 action. That gun has AT LEAST 1000 full loads through it and is still going strong and shoots wonderfully for a double. The Sable that I referred to above was taken at 208 yards, which is a good range for any double. I believe that that speaks well for the quality of these BRNO guns.

| Matabele |

| (.300 member) |

| 19/03/13 07:46 PM |

|

|

Hey Ron. I'm really glad to hear you had such a great time in Zim, its a beautiful country with some fantastic hunting as you obviously found out (good shot on that Sable by the way!). Kariba is food for the soul, Ive got some great memories of family holidays spent there, fishing and toasting G&T sundowners on a houseboat drifting with the current. A good pal of mine recently got married on an island in Kariba near Bumi Hills, that was one we wont soon forget! I know of Wayne although have never met him, Ive seen him around Bulawayo when he's in town. A great PH Im sure.

Hope you do make it back to Zim!! Cheers for now.

| felix |

| (.224 member) |

| 08/04/13 09:42 AM |

|

|

ron

the weight of rifles ?

and what size barrel ?

9.3x74

450#2

I'm doing a 500 nitro and do not know how much leave

regars

| Even |

| (.300 member) |

| 08/04/13 08:42 PM |

|

|

Ron, I really like how dark red your stock turned out. Fantastic color. I'd like to emulate that on a stock I have.

I see you used TruOil, and final finish with linseed, but what is the stain you use originally? It seems dark for Pilkington's English Red, unless its the multiple TruOil coats that make it that deep color?

| nitro450exp |

| (.333 member) |

| 09/04/13 10:44 AM |

|

|

Ron,

Very nice work, Bravo.

Nitro

| Ron_Vella |

| (.333 member) |

| 09/04/13 11:25 AM |

|

|

Felix, the .450#2 NE weighs 10.5 pounds without scope and has 25.5 inch barrels. The 9.3x74R weighs 9.5 pounds and has 26 inch barrels.

Even, The stain is Behlen's Blood Red. I buy it when I'm in the States because I've never seen it for sale in Canada.

| Even |

| (.300 member) |

| 09/04/13 08:18 PM |

|

|

Thank you sir, I'll keep an eye open for some. I've very much enjoyed this thread. Your craftsmanship is superb.

| Sville |

| (.400 member) |

| 09/04/13 11:12 PM |

|

|

Very good craftmanship in this project, nice work all of it!! /Staffan

| Caprivi |

| (.375 member) |

| 10/04/13 12:54 AM |

|

|

|

As to the Behlen's. Here is where I get mine, as well as a few other colors I use.

http://www.woodcraft.com/product/2007234/24144/behlen-solarlux-stain-blood-red-pint.aspx

As with most chemicals anymore, shipping by Air is stated as being prohibited.

Ron, just wonderful work you have done. Top nic. Not just the mechanics but the narative as well, we are all indebted to you for a great story line, Thank you for that.

| Caprivi |

| (.375 member) |

| 10/04/13 12:56 AM |

|

|

|

Postscript........ Behlen's Rottenstone is by far the best cutter I have used. I recommend it unwaveringly.

| DarylS |

| (.700 member) |

| 10/04/13 01:06 AM |

|

|

|

Very impressive, Ron.

| Ron_Vella |

| (.333 member) |

| 10/04/13 02:17 AM |

|

|

Are they holding you prisoner in BC? You never HAVE made it here for a visit!

| gallatin |

| (.224 member) |

| 04/05/13 06:35 AM |

|

|

Ron,

Can you speak a bit about the prep prior to soldering in the barrels into the monoblock? Does NEF threads allow enough room for the solder to flow, and pretining/fluxing is that different than say soldering the ribs in place?

Thanks in advance for your thoughts,

John

| Ron_Vella |

| (.333 member) |

| 06/05/13 12:58 PM |

|

|

John, Here's how I do it. Flow solder onto all of the mating surfaces of the mono-block and the barrels, using an ACID flux to wet the steel. While still hot and solder is molten, brush away as much solder as possible, using a brass-bristle, wooden handled brush, one of those ones about the size of a toothbrush that you see for sale at all of the gun shows. Once things are cool, wash everything well with hot soapy water to remove the acid flux residue, else you risk after-rusting of the assembly. I get someone to help me with final assembly because it really needs four hands. Start by painting all of the pre-tinned mating surfaces with a liquid ROSIN flux. Mount the mono-block in a bench vise, holding it by the under-lugs. Heat the shank of one barrel and the mono-block until the solder starts to melt, start screwing barrel into the mono-block, and feed solder, and more rosin flux as needed, onto the barrel threads. Continue this process until you have the barrel screwed VERY TIGHT into the mono-block. I find it best to switch things around at this point, gripping the barrel in padded jaws of the vise and using an apropriately-sized open-end wrench on the barrel lugs, for extra leverage, in order to get things REALLY TIGHT. Repeat with the second barrel and you are done.

| transvaal |

| (.300 member) |

| 07/05/13 02:54 AM |

|

|

Ron;

Have you completed the barrel regulation of the 9.3x74R, and if you have how is the accuracy?

Kindest Regards;

Steve Howell

| gallatin |

| (.224 member) |

| 10/05/13 01:29 PM |

|

|

Ron thanks for the info on solder and found an older post of yours on soft and high temp also. I notice that everyone who uses the existing monoblock leaves the rib on when cutting the barrels off.

Would it matter if one raised the top and bottom ribs prior to cutting Seems like there must be a good reason for leaving it on though I don't know what it is. Some of you thread the whole barrel shank and some thread a portion and leave a portion unthreaded, would an argument for this have to do with the shape of the bore and how much "meat" is left to thread. Thanks in advance for everyone comments

John

| Ron_Vella |

| (.333 member) |

| 16/05/13 07:08 AM |

|

|

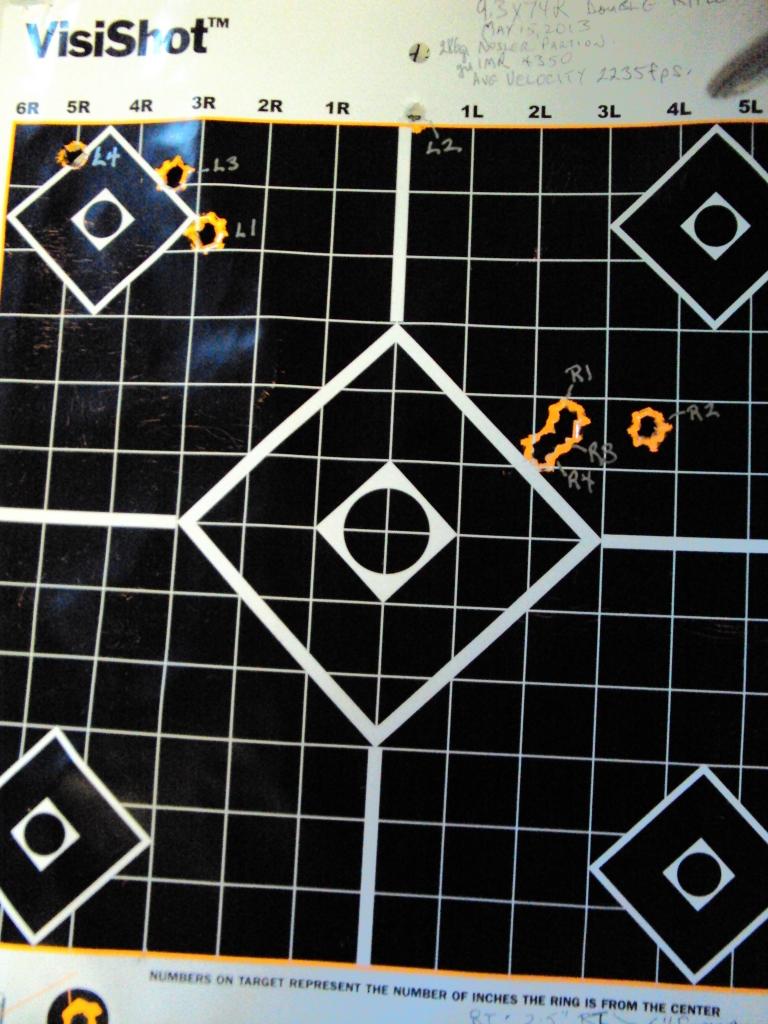

I finally got to the range today and shot this rifle. The attached photo shows the results. The barrels are shooting 6" apart at 50 yards and the left is about 3.5" higher than the right. The group from the right barrel, as you see is fabulous. The left is all over the place. When I got home I decided to check the crown on the left barrel and sure enough it had several bad burrs in it. I've honed those away and hopefully this cures the problem. I used my new regulating jig to bring the muzzles together by .006" and raise the right barrel by .003" relative to the left. Next shooting, probably Friday, will show the results of this.

| Huvius |

| (.416 member) |

| 16/05/13 09:17 AM |

|

|

|

Ron, I have to admit that I am envious of your abilities.

Building a double rifle of quality and accuracy must be one very gratifying experience.

| Rhodes |

| (.275 member) |

| 16/05/13 07:57 PM |

|

|

Good stuff Ron

.001" adjustment per 1" @ 50 yards

have you found this to be a good rule of thumb with your other doubles?

| Ron_Vella |

| (.333 member) |

| 17/05/13 02:26 AM |

|

|

Rhodes,

I've found that .001" per inch is a good place to start. Better to go up in small steps than to jump all over the place in large ones! No hard and fast formula though that I've discovered. It's more like the witches in the opening scene of Macbeth: "Double, double, toil and trouble...eye of newt..and all that jazz".

| Ckhobart |

| (.275 member) |

| 30/06/13 08:56 AM |

|

|

Stunning. Absolutely stunning.

| Ron_Vella |

| (.333 member) |

| 11/07/13 02:44 AM |

|

|

I have just returned from my club after firing this rifle for regulation. Two weeks ago I was not happy with the way the left barrel was spreading its shots. I spent some time with the two muzzle-crowning tools shown in the one photo, and three different grades of grinding/polishing compound. I also heated and adjusted the barrels using my new regulation rig (shown elsewhere). The results are startling, as you can see. I experienced the same dramatic improvement after re-crowning one barrel of a friend's .375 Fl. Mag. double a few weeks ago. Something to remember if you encounter a similar problem. I'm a happy camper today! Time to tear her down and start polishing and rust bluing!

[URL=http://s591.photobucket.com/user/ronvella/media/targets002_zps8e4d8eba.jpg.html]

[/URL]

[/URL]

| DarylS |

| (.700 member) |

| 11/07/13 09:41 AM |

|

|

|

Well done, Ron.

| gallatin |

| (.224 member) |

| 14/07/13 09:32 AM |

|

|

no kidding, great shooting.

John

| Ckhobart |

| (.275 member) |

| 15/07/13 06:40 PM |

|

|

Wonderful. I'd buy a rifle from you, if I wasn't intent on building my own

| Rhodes |

| (.275 member) |

| 16/07/13 06:54 PM |

|

|

Nice work Ron

I'd wondered how the muzzle crowns would hold up after having to re-profile a barrel.

I guess the answer lies above and you've found the solution.

Great stuff

Rhodes

| Rhodes |

| (.275 member) |

| 16/07/13 07:33 PM |

|

|

Ron

Have you tried running your loads through Quickload?

I'd be happy to input your loads at this end so you have a bit of a guide to the pressures you are developing. Within the limits of the software of course.

We've been using it work up loads with different powders in a 9.3 on this side of the pond. It's an invaluable tool when you don't have load data available.

You can send a PM if you wish.

Regards

Rhodes

| Ron_Vella |

| (.333 member) |

| 17/07/13 05:02 AM |

|

|

Rhodes,

I have not used Quickload. I'm using a relatively mild load from the newest Nosler manual, the 286 grain Nosler partition over 61.0 grains of IMR 4350. I see no pressure signs whatsoever but I'd be very interested in how Quickload rates that load.

| Rhodes |

| (.275 member) |

| 17/07/13 06:06 PM |

|

|

No problem Ron

I have

286gr Nosler Partition Bullet

61.0gr of IMR4350

24" barrel

If you could tell me the cartridge overall length of your loads, that will give me your bullet seating depth.

| Ron_Vella |

| (.333 member) |

| 18/07/13 06:16 AM |

|

|

Rhodes,

Here's the info:

barrel length: 26"

bullet length: 1.371"

overall cartridge length: 3.712"

seating depth: .584"

| Rhodes |

| (.275 member) |

| 18/07/13 07:55 PM |

|

|

ok first up to get the formalities out of the way. Anyone reading this should be aware that this info is only to be used as a guide and that actual results may vary, standard reloading and pressure measurement practices should be used on actual handloads.

Now the fun part.

Ron, this is what I get.

The red arrows show the fields I inputed with your data. I used COAL and Bullet Length as that is the most accurate way to determine the chamber space below the bullet. Everything else is generated by quickload. The results are in the red circles.

Calculated Pressure = 45,515 psi

Calculated Muzzle Velocity = 2,335 fps

This of course assumes all tolerances and powder burn rates are ideal. I see you chronographed 2235 fps which suggests to me the pressure of your loads are less than indicated here? If I reduce the powder charge until it matched your chronograph reading it shows ~41,000 psi, either way it looks to be a mild load as you say. I've also read that some users have found the estimates to be on the high side but I can't vouch for this either way.

hope this helps.

| Ron_Vella |

| (.333 member) |

| 22/07/13 12:07 PM |

|

|

Interesting info Rhodes, thank you. The velocity that I gave you is an average of 10 shots, 5 from each barrel, thru my Shooting Chrony, so it's pretty accurate.

| Rhodes |

| (.275 member) |

| 28/07/13 03:08 PM |

|

|

Ron

Definitely use your chrony result that you measured.

The takeaway from this is that your measured velocity is lower so your pressure should be lower. That's the way I see it.

QL is only a program so it's only as good as the data inputted. If, for example, your batch of powder had a different burn rate to the data in QL or it was affected by your different climate, it will give a different result. I remember stumbling across a discussion on here some time back about how IMR powders were climate sensitive and H powders were more stable. I think Daryl S was involved in this. Maybe he could chime in. Anyhow, not to drag the thread off topic.

| Ron_Vella |

| (.333 member) |

| 18/09/13 05:25 AM |

|

|

Here are a few photos of this rifle, finally finished to my satisfaction. I did 13 applications, boilings, and cardings until I got the rust blue just so. There are 30 applications of Tru-Oil, coloured with alkanet root on the wood. After each 10 coats, I let it dry for a week, then rubbed it out with pumice and boiled linseed oil on a felt pad. After the final go-round, I let it dry for a week and then also rubbed it out with rottenstone and boiled linseed. I'm pretty happy with the results, the gun looks good and shoots better than one could even hope for.

If any of you are at the Vintage Cup, I'll be there on Friday and Saturday and will have this gun with me if you're interested in seeing it. Look for the guy who's 6'10" tall and weighs 315lbs, that'

ll be me! Hopefully I'll get to use it on a big bull moose during the first two weeks of October.

Best to all,

Ron Vella.

| Ckhobart |

| (.275 member) |

| 18/09/13 07:40 AM |

|

|

absolutely gorgeous. Should try to get some daylight pics to do the wood and blueing justice though, if I might ask

| Ron_Vella |

| (.333 member) |

| 19/09/13 02:17 AM |

|

|

As requested, I have deleted yesterday's photos, which were taken indoors, and have posted some new ones which I took outdoors this morning. They are a bit better, I think.

| Igorrock |

| (.400 member) |

| 19/09/13 06:02 AM |

|

|

Nice rifle. It seems that you should have quite long arms (recoil pad looks thicker as usually...?)