| baileybradshaw |

| (.333 member) |

| 12/08/19 04:05 AM |

|

|

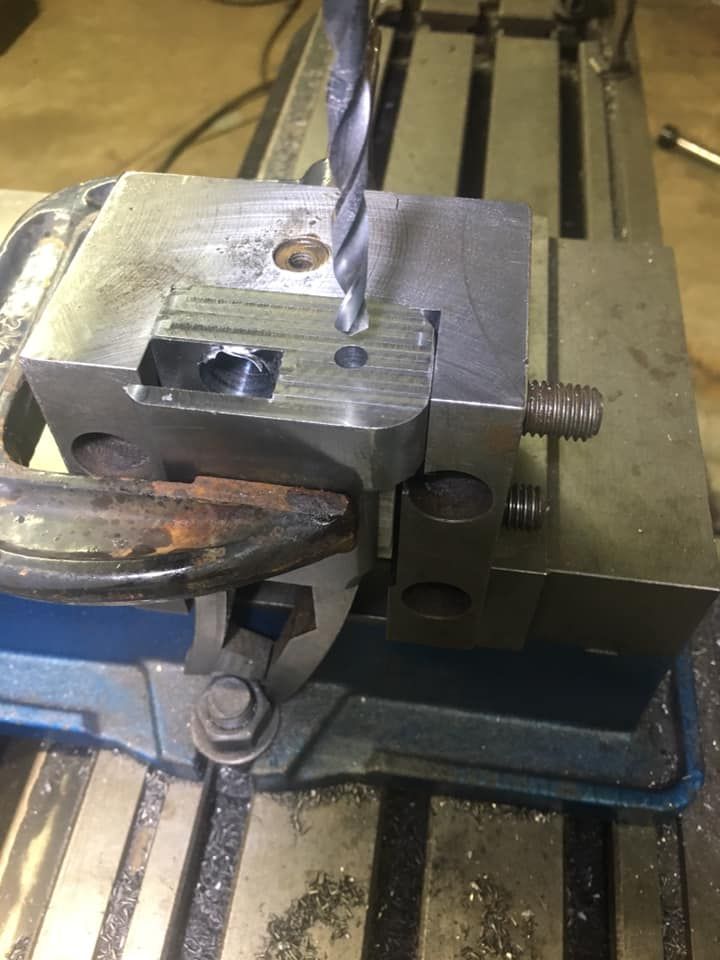

Set in another fixture dedicated to the machining of the face of the action and associated steps. A 2" deep hole is drilled at the center of the hole for the barrel. This establishes the center of the bore and the center of the pocket for the striker and that the two are perfectly aligned.

The face of the action is trued to ensure it is perfectly perpendicular to the bore. This is where the barrel seats and is a very important step to ensure accuracy. Not unlike facing the end of a bolt rifle action.

Now the hole for the barrel can be machined. The breech block is in the action during this setup, so the bottom of the barrel hole will form the face for the breech block in a very precise manner. Not only will it be perpendicular, it is also machined to a known depth allowing the machining of the barrel shank to be done to the exact length. The breech block is tilted forward 3 degrees, so accurately cutting the breech block face any other way would be far more time consuming and wouldn't yield the precision this setup offers.

Also, the picture below shows the location of the center of the bore is well below the top edge of the breech block pocket. This allows the full diameter of the chamber, and case thrust for firing, are fully supported in the action. Even though the breech block extends to the bottom of the action, this helps prevent the case thrust from torquing the breech block and further localizing the area of the action that would absorb the case thrust. Having the camber area fully supported keeps the distribution of the case thrust over a much more broad area.