| baileybradshaw |

| (.333 member) |

| 12/08/19 03:58 AM |

|

|

Building the first run of sidelever falling block actions, I've documented the process so far.

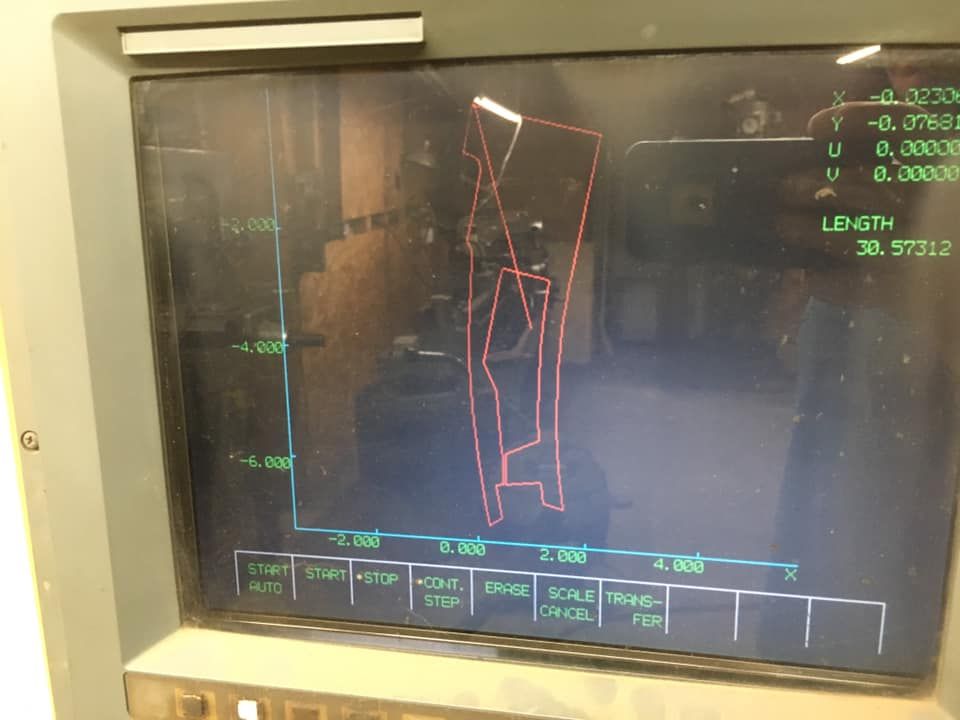

The first step obviously is to extract the action from the plate of 8620 steel in which it is contained. I am fortunate to have a wire EDM in house. While it is capable of far greater accuracy than is required for simply profiling the action, precision is never wasted.

Once the batch of action bodies are all profiled, holes are drilled to located the starting point for the wire path to cut the breech block cavity, and a fixture is made to hole the actions during the cut.

Breech blocks were wire cut before I started on the actions. The fit is extremely precise with .001" clearance for movement. Wire EDM is a very slow process and it's done under a powerful flush of water to cool the wire and clear eroded metal from the cut.

The tang surfaces are machined with tapers in both horizontal and vertical axis. There are also flats left on the interior edges of the tangs to index onto the inletting of the stock to negate any movement of the action once it's seated. Actions are secured to the stock with a drawbolt.

From there the pockets for the trigger group, cocking lever and extractor are machined. Also the hole in the side of the action for the sidelever stem.

Actions are flipped over and the cartridge trough is machined in. A mock assembly of the sidelever, breech block and trigger group housing ( also made before the action bodies were started) is hard to resist.