| DarylS |

| (.700 member) |

| 23/02/17 04:29 AM |

|

|

|

Use pure lead - or if using a .562" ball, a harder alloy could be used for deeper penetration, which is not needed up to moose or elk.

I use pure lead - as pure as I can get it.

X-ray room lead sheeting from the walls is a good source. The softer the lead, the larger the ball and better the potential accuracy you will get.

WW is too hard unless you reduce the diameter considerably. as the harder the lead, the harder it is to deform it to fit into the rifling with that patch. Loading becomes very difficult and you will also cut the patch. With dead soft lead, the ball and patch will conform into the lands and grooves, giving a perfect fit, excellent accuracy and clean shooting.

Use pure Neetsfoot Oil, or "Tracks" Mink Oil for lube for hunting. Smokeless powder lubes (mostly petrolium derivitives} do not work well with black powder fouling. The Mink Oil from www.trackofthewolf.com and Pure NeetsFoot Oil work very well.

I get my Neetsfoot Oil from the local hardware store in their "Tack" section for leather work.

Don't use Neetsfoot Oil Compound - that is a synthetic and does not work well with BP fouling.

A lube must be used that does not dry out while it is loaded in your gun, it must not 'foul' your powder and it must prevent the rusting that will happen in the breech if you use a water based lube.

In my .14 bore (.69cal.)rifle, I use mostly pure, dead soft lead with balls from my .682" mould for hunting. When shooting hardened lead, ie: 50:50 WW/Pure, or straight WW alloy, I use a 15 bore ball that measures .675". I still use the same patch, 12 ounce denim, which I meaure at .026" with mu mic, and .030" with the dial calipers, squeezing the tines as hard as i can between forefinger and thumb.

It is said (mostly by me-LOL) that you are never finished experimenting with muzzleloading rifle load combinations.

We've found that the larger calibres, above .54 that paper ctgs. can work very well indeed, for hunting generally, or for us, hunting in freezing weather where a good patch lube is difficult to find (stay soft and still work)

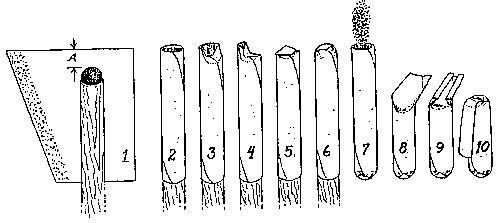

Here are some paper ctgs. I made and used in a replica Brown Bess. The same plug was used for my .69's paper ctgs. I made the plug tapered, as it is more easily handled, no wasted powder and easily fit in the muzzle due to the taper. I carried 1/2 dozen of these in my pocket all one fall's hunting season and they worked perfectly and stood up to the abuse.

2 wraps of about 20 pound paper. .682" ball, thus 2 wraps around the 'plug' - I used a glue stick for the wrap. Fold the bottom over. Pour in the powder, drop a ball on top and fold the paper over the ball and tie or glue. I used ordinary white paper glue.

To load, grab a paper ctg. from the pocket by the ball (heavy) end, tear the end off with your teeth, stick the torn end into the muzzle. By the time you have the loading rod out, the powder will have drained out of the ctg. Choke up on the rod (about an inch sticking out below your fist and shove the paper ctg. into the muzzle.

THIS is important- the paper ctg. must engrave slightly on the rifling all the way around - not an easy push as with grossly undersized paper ctgs. issued by the militaries of the world in the 19th century.

Once it is started, push it down in about 8" pushes until it is down on the powder - hard, compressing the paper between the ball and powder. When you fire it, the paper will act as a wad and seal the powder gasses behind the ball.

4 of us using these paper ctgs. have achieved the same accuracy as with cloth patched round balls. My .69 (14bore) can fire up to 10 accurate rounds with these- no lube is required. No fires either, due to the tight seal. If the powder gasses can blow past the paper, they will start it on fire!!!!!!!!!!!Caution.