| MikeRowe |

| (.333 member) |

| 25/08/12 05:08 AM |

|

|

This particular Steyr 6.5mm did not have it's original bolt, as evidenced by the fired cartridge case on the left.

We can either set the barrel back a turn and recut the chamber, or make a new bolthead .010" longer. As the bolthead was a little loose and sloppy, it was elected to make a new one. Should be done in an afternoon......yeah, right.

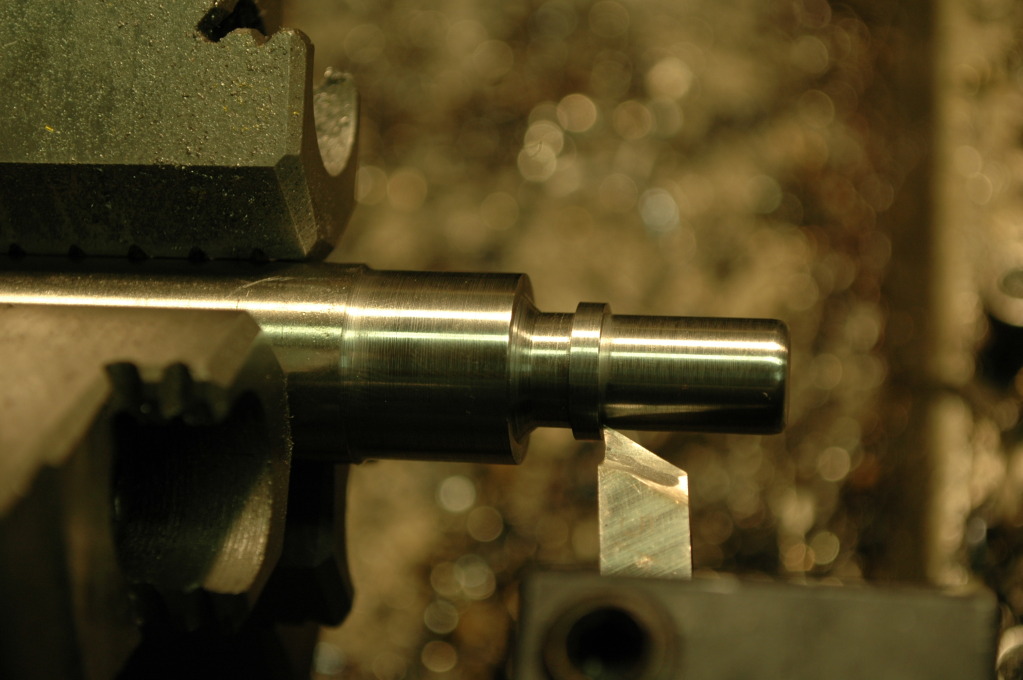

First, a blank head is turned on the lathe, being sure to leave a collar to machine the bolthead retaining lug.

Of course, as with almost every unusual job, there's a new tool to be made. In this case a .300" X 45 degree dovetail cutter for the ejector seat. Not too bad, about 40 minutes with the lathe, and filing in the teeth, and it's ready for heat treat. And there's always plenty of stuff around here ready to make a batch to go in my furnace.

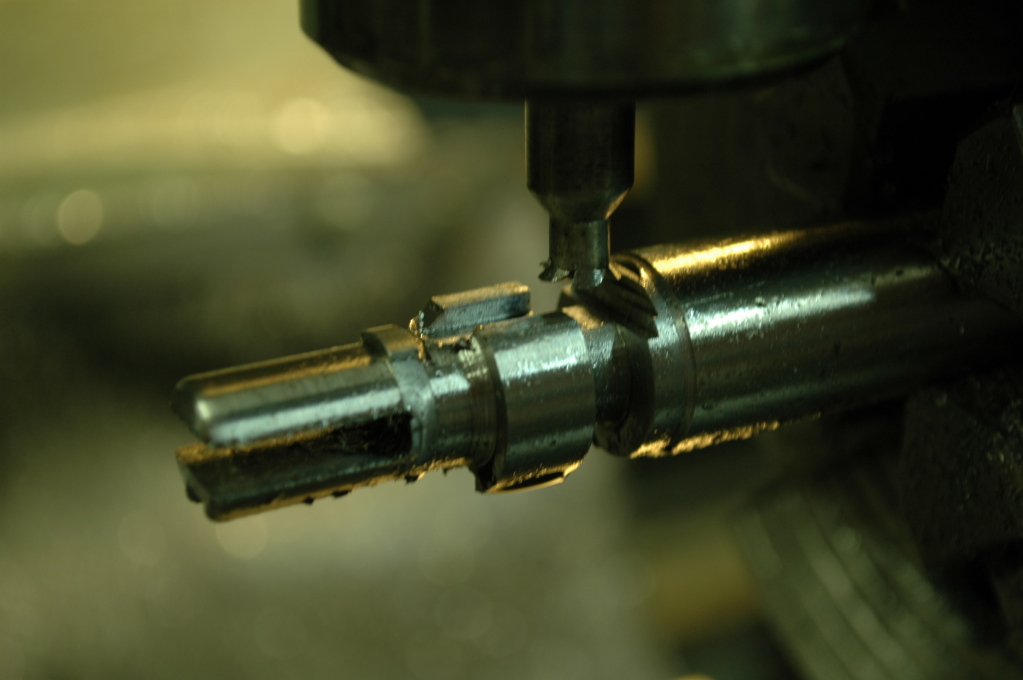

The blank is now chucked into the dividing head on the mill and dialed in to center with a test indicator. This will make indexing easy and accurate.

Most of the collar is pruned away, leaving the retaining lug to keep it in the bolt body.

The slot's cut for the firing pin, and then the extractor slot. Must remember to leave it a little narrower at the rear so the dovetail can be cut to retain the extractor.

Now I get to try out my new dovetail cutter.

That worked very nicely. The little pocket for the tip of the ejector retaining screw is next.

Back to the lathe, and using a specially ground drill bit, the firing pin hole is formed and reamed.

All polished and ready for heat treatment.

Out of the fire, repolished and final fitted to the body. Ready for testing.

And the cartridge on the right in the first photograph is the result.

An afternoon had morphed into a day (a long one)...oh well.