| underlever |

| (.300 member) |

| 02/01/15 12:33 PM |

|

|

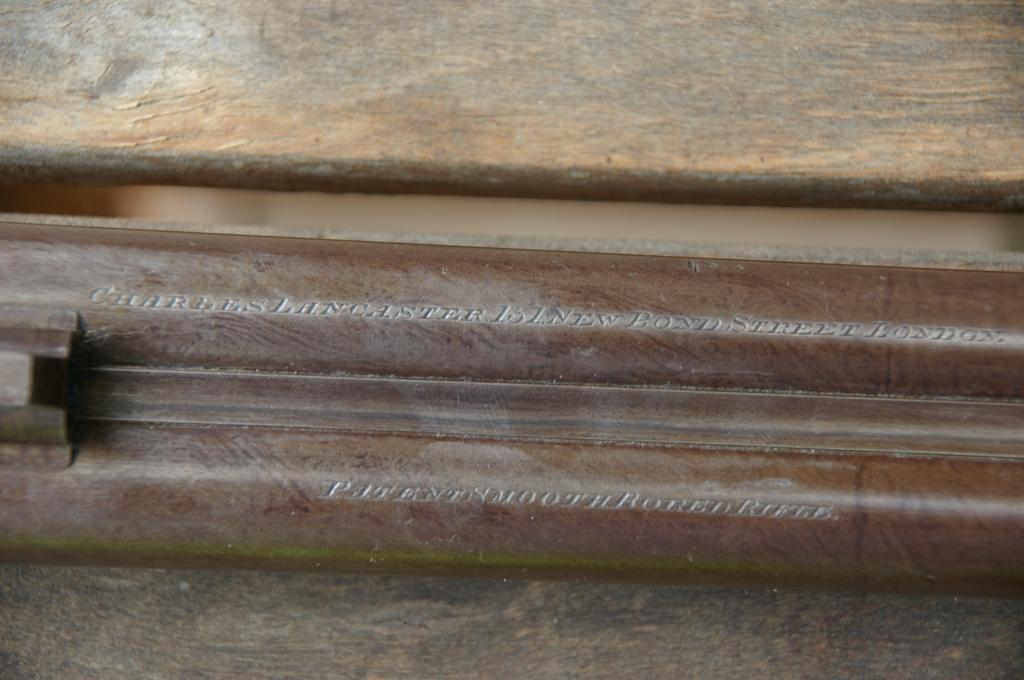

Made approx. 1852, this is as fine a double as I've ever seen. The quality of this rifle is such that I believe it cannot be improved upon. Barrels are 31 15/16" long with bores that measure .490"x .535" and in very good condition.

After playing with this rifle for awhile, I've come to the conclusion that the double rifle had been perfected by this time, maybe even earlier with only technical advances occurring.

There is no standing rear sight as part of the usual set up but for the short range stuff you simply use the notch in the standing breech. Due to the fit of this rifle, its all you need.

| tinker |

| (.416 member) |

| 02/01/15 01:04 PM |

|

|

|

That'll do.

What's the charge?

What's the bullet weight?

How does it print?

So Nice!!!

Cheers

Tinker

| TH44 |

| (.375 member) |

| 02/01/15 01:21 PM |

|

|

The late percussion rifle had everything going for it - quality all round. Charles Lancaster produced some of the best

The arguments/discussions pro/con breechloading went on for years, especially where rapid reloading was less of an issue - live pigeon shooting etc.

Interesting the number 2 on the barrels, usually one of a pair but clearly not in this case

The shallow vee with the fold flat sights is a nice touch, as is the earlier straight stock with finger rest

Is there a bore size under the barrels? 32? - I have always been interested how his "oval" bore measured

Very nice

TH44

CptCurl

|

| (.450 member) |

| 02/01/15 11:39 PM |

|

|

|

That's a superb rifle and will be really fun to shoot. Please give a range report in due course.

Congratulations!

Curl

| Huvius |

| (.416 member) |

| 03/01/15 03:21 AM |

|

|

|

Lovely rifle!

Does the mold cast an mildly ovoid bullet to fit the bores?

I wonder, are they intended to be patched as a roundball would (but they are hollow based...) or paper patched (but no parallel sides...) or left bare lead?

| LesLeeSpeed |

| (.300 member) |

| 03/01/15 09:46 AM |

|

|

|

|

Hi,

I once owned a Lancaster Oval Bore 500BPE D/R and I believe they were meant to be paper patched. It is a beautiful rifle, and one of many that I shouldn't have sold, but such is life. I think that mould is a solid base ant that is not a hole for a plug but the sprue hole. The sprue would be cut probably by the shanks of the mould handle. Being a M/L i would think that the patch would be fitted as you loaded, but would need to be pretty tight.

Just my thoughts.

LesLeeSpeed

| DarylS |

| (.700 member) |

| 03/01/15 10:32 AM |

|

|

|

Absolutely incredible - what a wonderful SCORE!

The mould pictured is a bit longer in the nose, but typical

"PICKET" bullet shape, meant for a cloth patch. The rounded base and VERY short, almost non-existent bearing surface shows this.

As thus, it will be difficult to load squarely, so a short starter cupped to fit both the bullet's nose and quite close to bore size will be necessary for accurately loading the bullet. The end of the loading rod used to push the bullet down on the powder charge, will also need to have am almost bore riding nose, with a hollow to also fit the bullet's nose.

You should attempt to measure the rate of twist - if 48" or slower, a round ball loading, say a .490" ball and .020 patch might be easier to get good accuracy. Special bore riding noses on starter and loading rod are then, not necessary.

I am either seeing evenly spaced lint in the muzzles or what looks to be the ends of lands. If lands, it is not oval bored, but has more standard rifling.

.535" groove with .490" bore, shows VERY deep rifling for a bullet - ie: .0225" deep per side. That is even deep for patched round balls, the norm being .010" to .016" at the deepest.

This depth of rifling definitely mandates a cloth patch and a thick one at that. A

Accuracy might be difficult until the muzzles are smoothly crowned as well. They may already be relieved by deliberate filing, as were many German rifles meant for patched balls or bullets.

Please keep us posted on developments.

The "tubes" as they were wont to call nipples, will most likely need to be replaced. Please be careful in their removal. Many of these guns had poorly designed nipples, with oversized inner holes. This lets too much pressure back out the nipple and is shocking for the lock, not to mention cap fragments flying about your shiny eye-ball/s.

| Huvius |

| (.416 member) |

| 03/01/15 11:30 AM |

|

|

|

Quote:

?..I think that mould is a solid base ant that is not a hole for a plug but the sprue hole.

Duh!! For some reason, I just assumed there was a base plug but failed to think just how the lead would be poured in!

Gives me an idea!

How about a mold such as this with a good sized cylinrical sprue upon which donut shaped wads could be stacked?

That would insure that the bullet goes down the bore straight and if made of lubed felt, would seal the oval bore nicely.

Not sure if the wads would shed without upsetting the bullet path, but it could work. The bullet would be like a dart.

| rglenz |

| (.300 member) |

| 03/01/15 12:09 PM |

|

|

Huvius,you maybe on to something! Your idea would explain the big sprue,also I think I see a cutter notch in the handles,next to the mold.If this is the original mold it would help explain how the oval bores worked with bullets.

| Huvius |

| (.416 member) |

| 03/01/15 06:40 PM |

|

|

|

Quote:

Huvius,you maybe on to something! Your idea would explain the big sprue,also I think I see a cutter notch in the handles,next to the mold.If this is the original mold it would help explain how the oval bores worked with bullets.

Hmmmm...

If that is a notch in the scissor part of the mold, then the resulting sprue would be about half its as-cast length which would make a nice post for a .20-.25" wad to sit on.

I don't necessarily think that is how these bullets are meant to work, but it sure would make sense to me and wouldn't it be a neat project to try out?

| DarylS |

| (.700 member) |

| 04/01/15 04:11 AM |

|

|

|

Sissor-type moulds with sprue cuttoffs usually had them on the handle end of the hinge pin of the mould handles.

The rifling twist will dictate how long you can make the 'sprue'.

Attaching wads to it, might be a good idea - or not. Testing will tell that story.

Still looks like a 'typical' American picket-type bullet to me.

Yes- the addition of wads would help centre the bullet.

What is the diameter of the inside cavity of the mould? Subtract about .002" for actual bullet size in soft lead, which is probably correct for the gun. Hardened lead makes loading more difficult to impossible in a muzzleloader and will eliminate the bullet's ability to obturate to help seal the bore.

The sprue cutters normally cut the sprue off square with the base or nose of the bullet.

| weimar |

| (.224 member) |

| 26/04/15 10:35 PM |

|

|

I would be interested to know the serial number