| buckstix |

| (.400 member) |

| 10/10/13 01:20 AM |

|

|

|

Hello All,

I watched this Eduard Kettner 9x58R double rifle on Auction Arms for many months. I didn't have a 9mm double, so it interested me. This was the listing.

http://www.gunbroker.com/Auction/ViewItem.aspx?Item=366234502

Little by little, the seller reduced his price, and finally he accepted an offer, that made this an affordable "curiosity" that wanted to move to Wisconsin. I say curiosity, because I've never seen a "pop-up" cheek piece before. A clever idea for shooting with/without a scope. The claw mount bases are still there, but unfortunately no scope. I'm sure I'll spend the rest of my life searching the nooks and crannies of gun shows, to find a scope that will fit.

The rifle is in "very used" condition with several dings and slivers of wood missing. Likely a WWII bring-back that was mistreated when gathered. But this is mostly cosmetic, and those things that count, bore, lock-up, etc, are all very good.

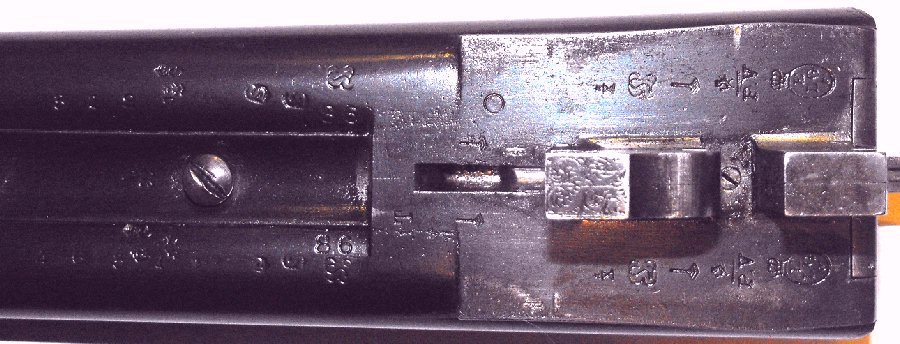

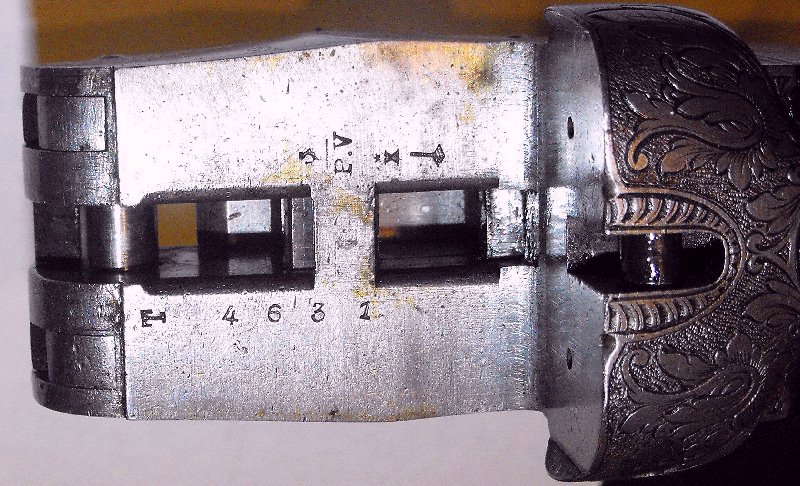

With all the Belgium proofs, I'm assuming Eduard Kettner was only the seller. I think there are a couple of German proofs, but I'm not sure. That's why I'm posting this. Perhaps one of you can decipher the stampings. I'd be particularly interested to know the "year" of manufacture, and who might have made this rifle.

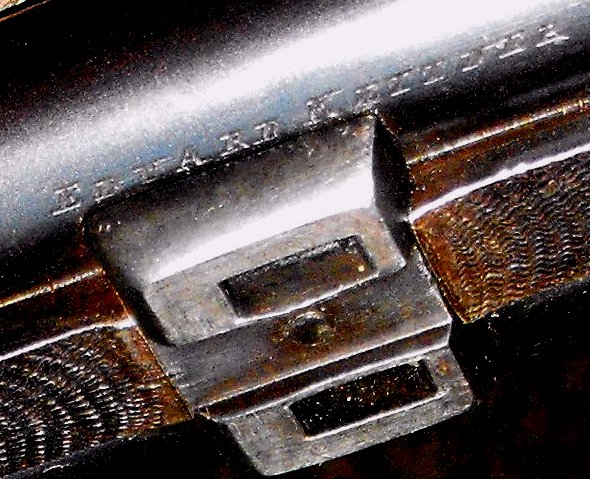

The barrels are marked "Eduard Kettner" on one barrel, and "Koln, A./RN" on the other. Anyone know what "A./RN" means? The seller listed the caliber as 9x58R "Sauer" - and "verified". I've soon found that there is absolutely NO brass or dies available for this cartridge. Apparently Sauer had his own line of cartridges based on his own idea of appropriate case dimensions. Custom dies from chamber casts would be 6 - 10 months in waiting. I don't think I can wait that long. I just don't have the patience.

Here are some pictures of the rifle.

Since I didn't have the patience to wait for custom reloading dies, and since I already own over 300 different sets of dies, I figured I could "mix & match" dies to get the 9x58R cases reloaded. But first I needed the brass cases. Here again, custom cases would be 2 - 3 months in waiting.

So, I decided to quickly more forward. There are only 3 cartridges that are even close the this strange caliber. The 303 Savage is the closest, with only rim thickness being an issue, but the case is .300" too short. Both the 303 British and the 30-40 Krag have rim thickness and rim diameter issues, and both are "oversize" and longer, but the 303 British is still .050" too short. The 30-40 Krag is therefor the "best" choice; but I didn't have any of those, so I had to use the 303 British. The loaded cartridges below, show the bullet's crimping groove in the correct position had the case been the required .050" longer.

Here are the 16+ steps required in making the brass for this caliber. I'll go through the steps for those that might want to make their own 9x58R brass someday, although I doubt many have rifles were made in this caliber.

1. Once fired 303 British case.

2. Resize in a 303 FL Die.

3. Expand neck with a 338 Win Mag die.

4. Expand neck with a 9.3x74R die.

5. Partial resize in an 8x58 FL die.

6. Use "shave die" (modified 303 Savage FL die) to reduce case head. (partial stroke)

7. Use "shave die" to reduce case head. (re-lube & partial stroke)

8. Use "shave die" to reduce case head. (re-lube & final stroke)

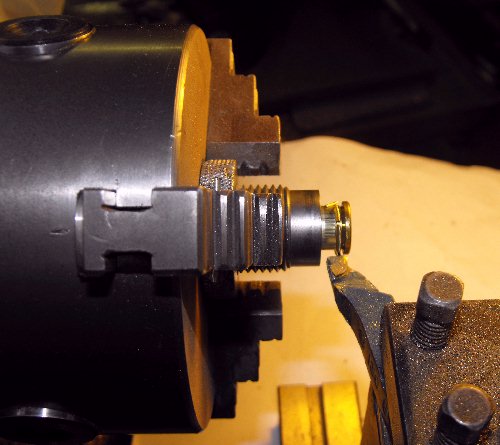

9. Remove curl with lathe.

10. Reduce rim dia with lathe.

11. Thin rim with lathe.

12. Partial resize (modified 30-30 Win FL die)

13. Use "shave die" to reduce case head. (bottom against rim)

14. Cut rim groove with dremel tool cut-off disk and uniform case head (if required) with file.

15. Full length polish case with 360g emery paper.

16. Resize neck & load using 35 Rem Dies.

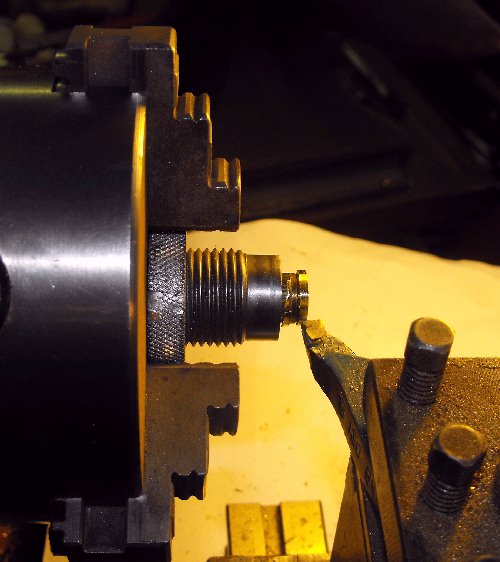

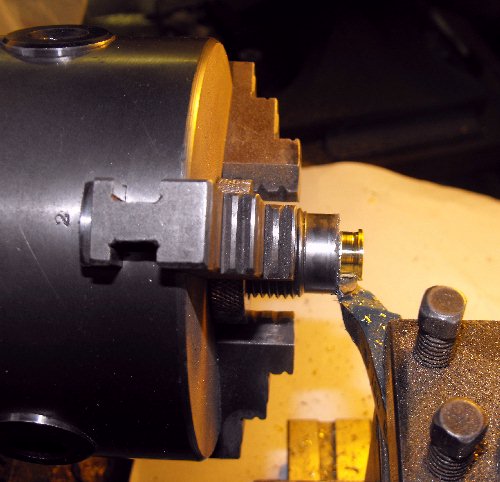

This is the "shave die". It is made from a "cut-off" 303 Savage FL die. The sharp edge of the die, shaves the excess material that is too hard to re-form by sizing. It takes several strokes of the press with re-lubing the case between each stroke. This requires a lot of force and a good press.

After the shave die and case are cleaned to remove the lube, the shave die is used to hold the case for the the several lathe operations to the case head and rim.

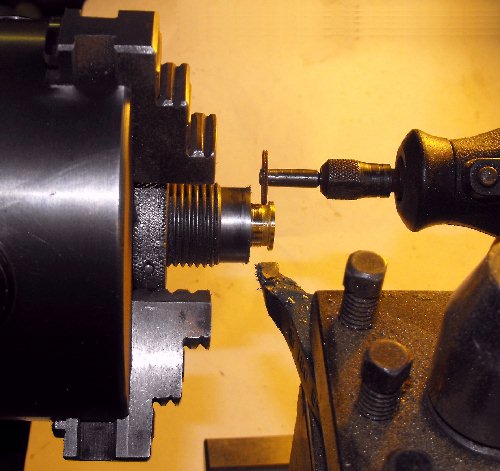

A cut-down 30-30 Win FL die is used for partial resizing of the case body. I use a dremel tool with a cut-off disk to cut through the reloading dies. Sometimes it requires several cut-off disks to complete the job.

It took approx 5 hours to manufacture 37 cases. I started with 40, but had 3 losses along the way. Although there are a few minor cosmetic variations in the case heads and rims from case-to-case, I don't expect they will affect the function or accuracy when shooting the cartridges.

Later today, I plan to go to the range to test the loads and fire-form the cases for this new addition. Case volume and pressures are very close to that of the 35 Remington, so "starting" data for it was used in working up the loads for this cartridge. I'll keep you posted on the results.