| Ripp |

| (.577 member) |

| 07/09/08 02:20 AM |

|

|

This was in a newletter I get monthly via email from Barnes---thought those who reload and shoot doubles would find this interesting...

Ripp

Here’s a test question for you: True or false? Barnes Banded Solids create higher pressures, and therefore should not be fired in some double rifles, particularly older guns with softer barrel steel.

Answer: False! Read on. I’ll explain why and bolster our case with test data.

Rumors are floating around on internet forums, chat rooms, blogs and by word-of-mouth that some firearm manufacturers are recommending full metal jackets or soft points only for use in their rifles, no mono-metal solids. Because our Banded Solids are in the mono-metal class, customers have asked for our feedback. More specifically, people want to know if our Banded Solids create higher pressures than the competition’s jacketed soft points and full metal jackets to the point their rifle could be damaged. For the record, we’ve been presented with one occurrence of this nature to date, but it didn’t involve a Barnes solid. Holland & Holland reported to us that a monolithic solid manufactured by another company actually damaged one of their rifles. However, this particular company was at one time using melted down, reclaimed cartridge case brass to manufacture their monolithic solids. Barnes has always used pure, virgin material for our Solids, and now Banded Solids.

According to some blog and forum posts, there are a number of factors involved that must be taken into account such as barrel thickness and even the age of the barrel. Let’s look at the facts. Mono-metal solids are made of a solid alloy such as bronze or brass. Full metal jackets are made from a steel cup with a copper wash applied to the surface of the steel. A lead core is inserted in the base and the “cup” is then closed to form the base of the bullet. If what these folks are saying is true about thin barrels and older steel being more “sensitive,” then wouldn’t steel on steel produce a higher friction coefficient than brass alloy on steel?

The Barnes Banded Solid is slightly under-sized. We do this to accommodate the great variety of tolerances found in double rifles. It is a fact that some double rifle barrels are out of spec on bore and groove diameters. In a perfect world we would build bullets to fit each individual throat and barrel, but this is simply not feasible. So we try to build bullets that will work safely for the majority. SAAMI requires that diameters on all sporting rifles not exceed +.002”, but double rifles were being built long before SAAMI came into existence.

The material used to manufacture Barnes Banded Solids will not obturate at less than 45,000 psi. So how is it that a turned bullet, slightly undersized in diameter, held to precision tolerances on a CNC machine that will NOT obturate, create excessive pressure or damage a barrel that is even close to within spec? I submit that a full metal jacket comprised of a .003” thick copper-plated steel core engraving into the lands and grooves is going to be much harder on a barrel.

To further reduce bearing surface and pressure, Barnes has cut a series of grooves in the shank of the mono-metal solid that provides any material displaced by the lands someplace to go. Full metal jackets do not have this feature. Steel on steel is not the desired scenario for a rifle barrel, especially if what people are saying is true about the older barrels being made from softer material. Is the steel in the jacket material softer or harder than the barrel steel? In general, we don’t know the answer to this as the metal used for double rifle barrels has varied to such a great extent over the years. However, we know for a fact that the brass in Barnes Banded Solids IS softer than barrel steel. We also know that the grooves cut in the shank provide an area for the softer material to displace.

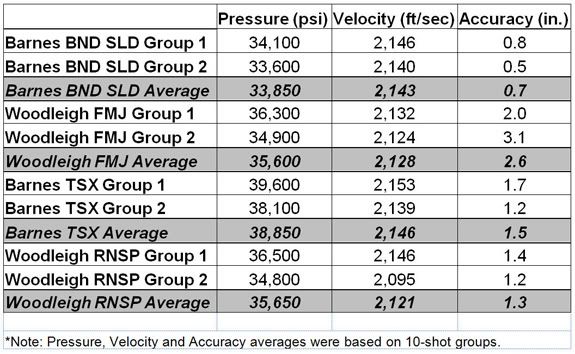

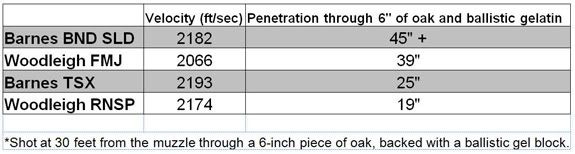

Still skeptical? Of course you are. You want proof and we figured you would, so we performed pressure tests. Hopefully, the results will put this myth and your mind to rest. While we were at it, we shot some penetration tests to compare Barnes bullets with one of our leading competitors on the African market.

I believe the “high pressure with all mono-metal solids” propaganda was spread via the old “someone heard something from someone” and so on, and so on. If someone out there is aware of an actual case involving pressure issues with BARNES mono-metal solids, I would ask that these people contact Barnes personally. We would like the opportunity to investigate any such claim. Based on our tests and experience, I’m comfortable stating that Barnes Banded Solids are better for antique barrels than the competition.

For our test, we fired 500 grain bullets in a 470 Nitro test barrel with 85.0 grains of RL15, Norma brass and Federal 215M primers