| banzaibird |

| (.333 member) |

| 10/02/07 12:07 AM |

|

|

|

Posting Pics for Ron.

1) My workshop, AKA the "Sanctum Sanctorum"

2) Rifle barrels, screwed and soldered into the monoblock. Top rib and sights set in place.

3) Close-up view of quarter rib with Weaver bases screwed and welded into place. Rear sight is a NECG from Brownell's, and has been rough-filed for elevation.

4) Hi-Viz front sight and NECG window hood from Brownells. Top rib is from Crown Press but I have modified it a great deal.

5) You can just make out the seam here between the rifle barrels and the monoblock.

6) Bottom view of rifle barrels with bottom rib from Crown Press screwed into place and sling swivel base installed. I like to screw the ribs into the barrel spacers, as well as soldering them. This takes some of the load off of the solder joints when you're carrying a heavy rifle on a sling. It also ensures that the rib is not going to let go and leave you stranded in the middle of Africa.

7) The rifle barrels on the action with the fitted shotgun barrels below. Note that both sets of barrels have their own forearm assembly and all pieces are now serial-numbered alike.

8) A second view of the same.

9) Close-up view of Leupold Vari-X III, 1.5x-5x, clamped onto Weawer bases with Leupold QRW rings.

10) Over-all view of the same.

11) Looking down the iron sights.

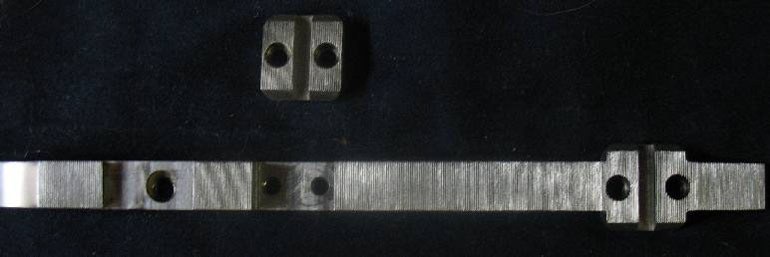

12) This is the steel Weaver base stock from Brownells that I welded on to the rear of the top rib from Crown Press and milled as seen in photos.

13) View of barrels, spacers TIG-welded into position, muzzle wedge in place, and both ribs lying below.

14) Quarter rib with the front QD base removed from its mortise. I matted the quarter rib and the front ramp with a 50 LPI checkering file,

15, 16, & 17) close-up views of barrel spacers, welded into place.

15, 16, & 17) close-up views of barrel spacers, welded into place.

15, 16, & 17) close-up views of barrel spacers, welded into place.