| transvaal |

| (.300 member) |

| 04/04/17 12:24 AM |

|

|

Of course, after regulation of the barrels of this DR, was the fitting of the original buttstock to my dimensions, reforming of the piston grip, checkering, leather covering a Pachmayr deaccl. recoil pad.

A few comments about the Brno zp49 double shotgun action to use as a DR action. I think that Ron Vella of Canada has demonstrated that these actions can be used with a number of lower pressure cartridges, and he has shown that on previous posts on this BBS that you can find.

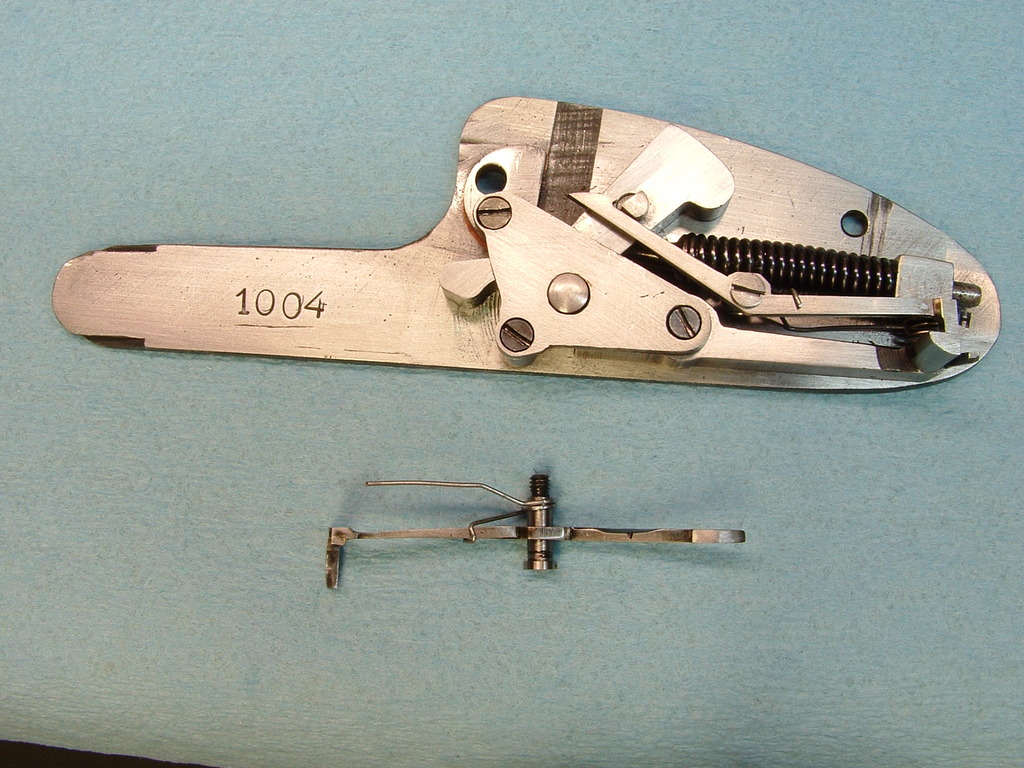

These actions are coil spring side lock of the backlock design, and they use the typical Holland style cocking levers to engage directly with extensions of the lock tumblers to cock the tumblers. The cocking levers are very robust. Within the forward portion of the cocking levers is milled an area for the tripping levers for the activating the individual right and left side ejector kickers. The ejector system is of the Southgate design. The fore-end metal is robust as well and can be lightened by milling away and you can reduce its weight by 4 ounces.

However, one item that a DR needs, safety intercepting sears, are not a Brno zp49 component. I therefore set about to design and install a prototype safety intercepting sear for the action. The design I dreamed up is loosely based upon John Robertson's (Owner of Boss in early 20th century) Boss gun and rifle safety interrupting sear.

It is of interest to me and will be to you as well that I have not seen a safety intercepting sear that will allow the gun to be fired by pulling the trigger on the lock after the safety intercepting sear has been tripped. Let me explain with a hypothetical example: "You are on a Cape Buffalo hunt and a Cape Buffalo suddenly appears from nowhere and charges you at short distance. You fire the right barrel and hit the Buffalo, but he is still coming at you. You go to fire the left barrel and it will not fire no matter how hard you pull the trigger. For some reason the safety intercepting sear has tripped on the left side lock--maybe it was recoil from the right barrel firing that caused it. Nevertheless you are going to have to get away from the charging Buffalo quickly if you can."

It would be good to have safety intercepting sears that if they tripped and held the tumbler in position from accidental firing, that even though they held the tumbler in this position you could with extra pulling effort fire the DR.

That is the way the prototype safety intercepting sears work on my DR.

You will see from the photo that the lever that prevents the tumbler from moving forward and contacting the firing pin (strikers), is prevented from doing so by an extension mid way on the tumbler. I added this extension to the existing tumbler, by first removing and annealing the tumbler then drilling and tapping a size 8-32 screw thread hole and inserting a 3/32" diameter short section of O1 drill rod into the hole. Of course, the section of O1 drill rod had a smaller diameter portion that I had turned and threaded to 8-32 size. And upon further observation you will see that the larger diameter portion ("tumbler stud" is what we will name it) of the O1 rod extending from the tumbler is milled to an angle that mates to the angle of the top hook section of the intercepting sear lever.

For whatever reason that the safety intercepting sear of this design occurs the tumbler moves forward under its mainspring tension, but only moves .020"-.040" distance and is stopped and held by the hook to tumbler stud contact. However the angle of the tumbler stud forward surface and the angle of the intercepting sear lever hook is of such an angle that if one pulls hard upon the trigger (7-9 lbs of pull) the intercepting sear hook will move down from the tumbler stud and allow the tumbler to contact the striker and fire the DR. The intercepting sear lever is made of high strength alloy steel and hardened in order to withstand use as I just described.

the tumbler is rehardened and tempered. The tumbler stud is hardened and tempered as well, but is hardened and tempered individually-not while it is screwed into the tumbler.

The hardening and tempering of a lock tumbler must be done very carefully leaving the bent surface hard but not liable to chipping away during use, while leaving the cocking extension portion of the tumbler hard enough not wear away and the upper portion of the tumbler that contacts the striker hard but not so hard that it might begin to crack. If one has modern proper alloy steel to make a tumbler with, the entire tumbler can be heat treated the same throughout. Since I did not know the alloy of the steel of this Brno lock tumblers I heat treated them the way I just described.

Of course as you will notice I had to drill and tap a hole in the lock plate for the intercepting sear lever as well as make a pivot screw and a hair spring to hold the intercepting sear lever upwards.