| transvaal |

| (.300 member) |

| 29/03/17 03:25 AM |

|

|

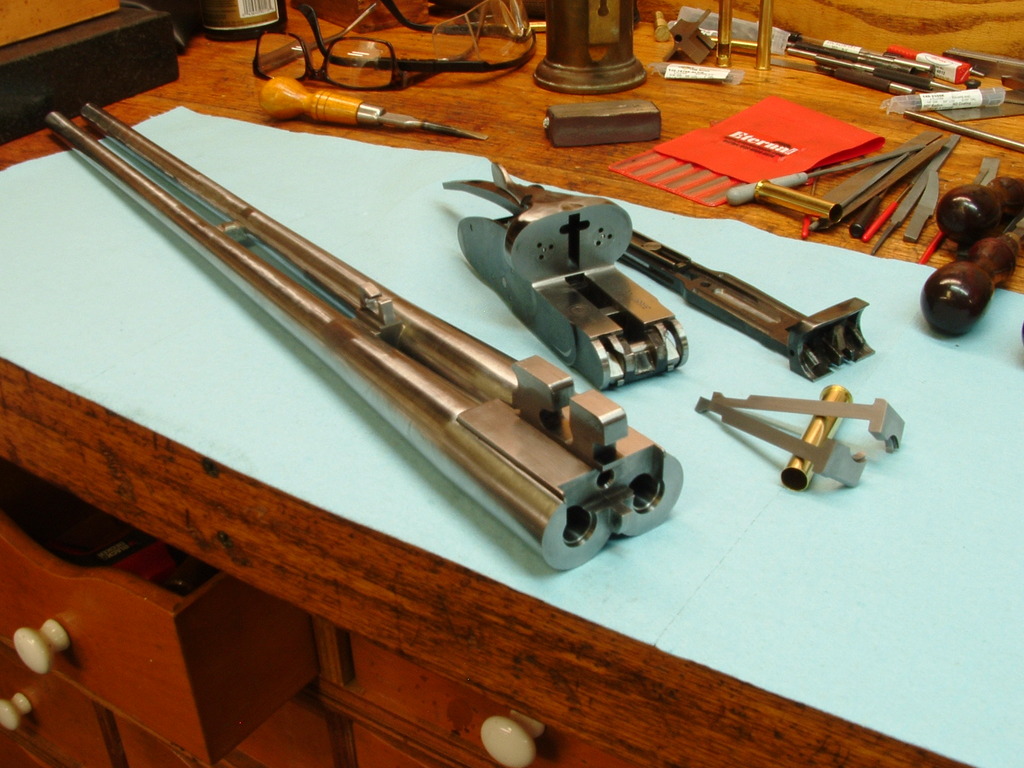

You will notice that the diameter of the thru-hole for the extractors is small (7/32). It is small as I wanted reduce risk of removing too much metal. Therefore I chose a very strong hard steel alloy (O-1) to make the two extractors. Also as the extractor shaft diameters are small the construction of these needs to be of solid one piece material, to my mind. No welding.

The method I used to make these two extractors was to mill a round bar of O-1 and chuck the flattened bar in a four-jaw chuck in the lathe and cut away everything I did not want--this is the way of the past and the future way of constructing something like these extractors is additive machining not subtractive. A better way to have done this using the old method was to have forged a section of O-1 down to nearly the size I needed then turned it with the lathe. However, where in the past I would have done this, Arthritis in my hands makes it so painful to hold a hammer while forging on the anvil, that I can no longer do any forging of this type.

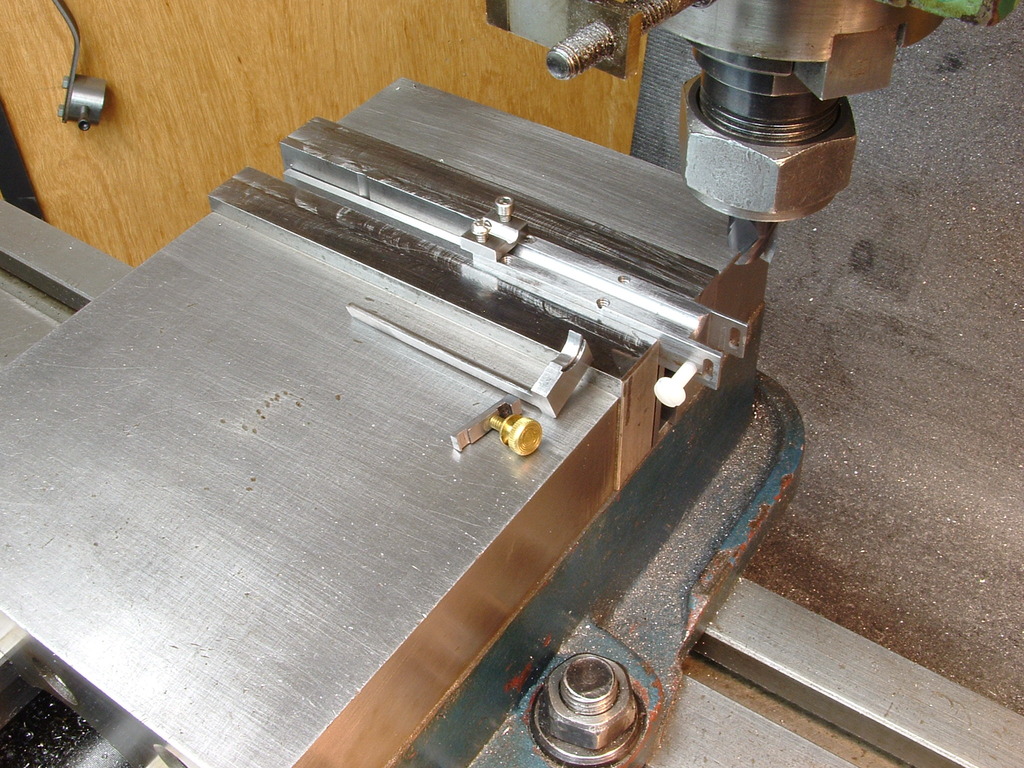

Of course the old method that I used is a long process and wastes a lot of expensive alloy steel, but here are some photos. I have included a photo of the fixture-jig I built to hold the extractors where they can be machined very accurately horizontally into two halves. The two extractor halves were heat treated. Fixtures can be made to hold extractor halves, but machining a bar of steel exactly square to all sides, then while the extractor fixture remains in the mill vise from the last machining (of the 4 mills cuts to make it square all around) mill a slot horizontally with a ball time milling cutter (in this case 7/32" milling cutter)to a depth a few thousands of an inch less than 50% of the diameter of the extractor shaft needed. Although I do not have a photo that illustrates the the cross pieces retainers that I made to hold the extractor firmly in place during milling, you can see the threaded holes in the top of the fixture and have a good idea of how they work. I made provisions for three cross piece retainers. I do not like this extractor fixture design I made and will make some other design in the future as needed.