| transvaal |

| (.300 member) |

| 28/03/17 03:20 AM |

|

|

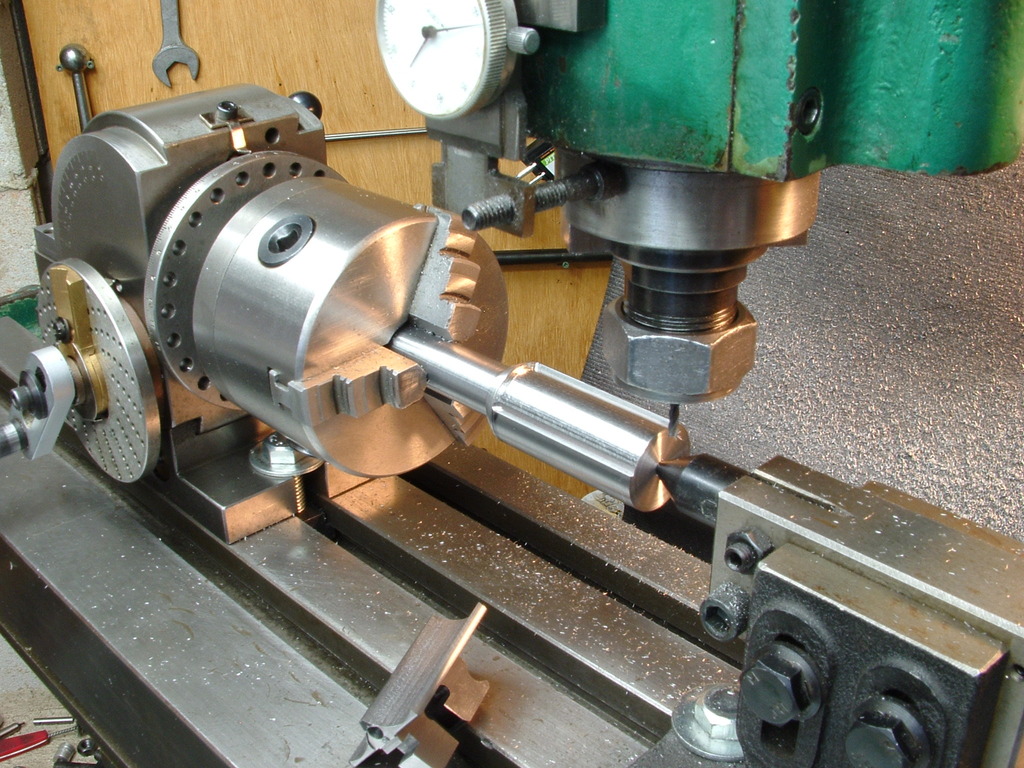

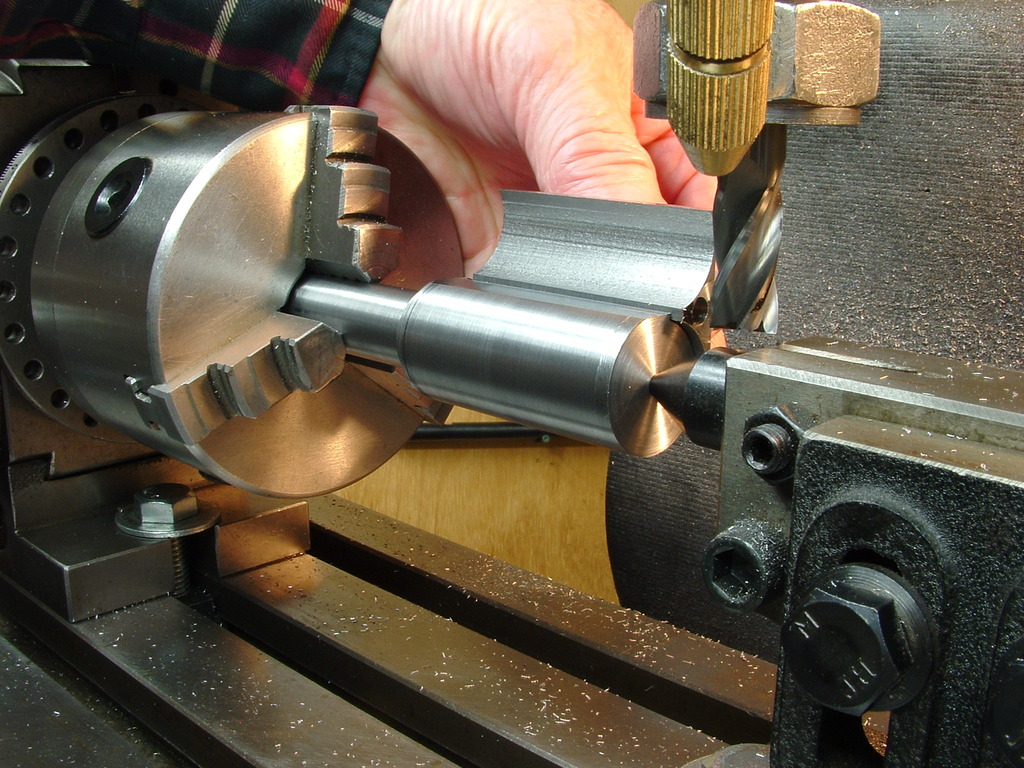

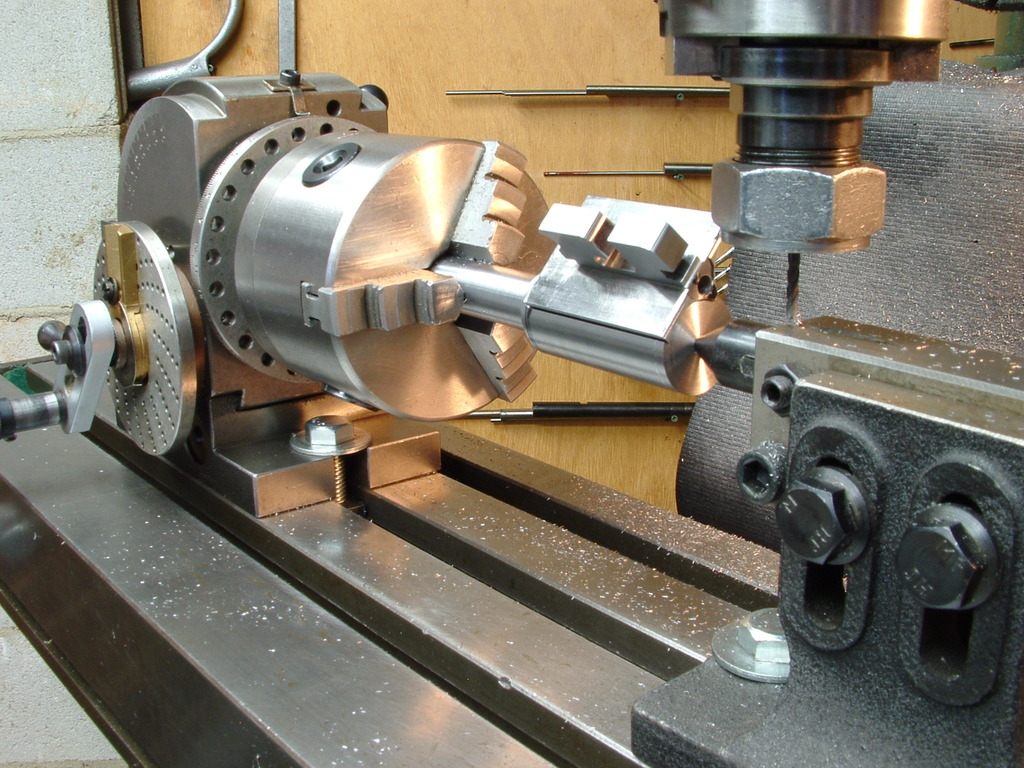

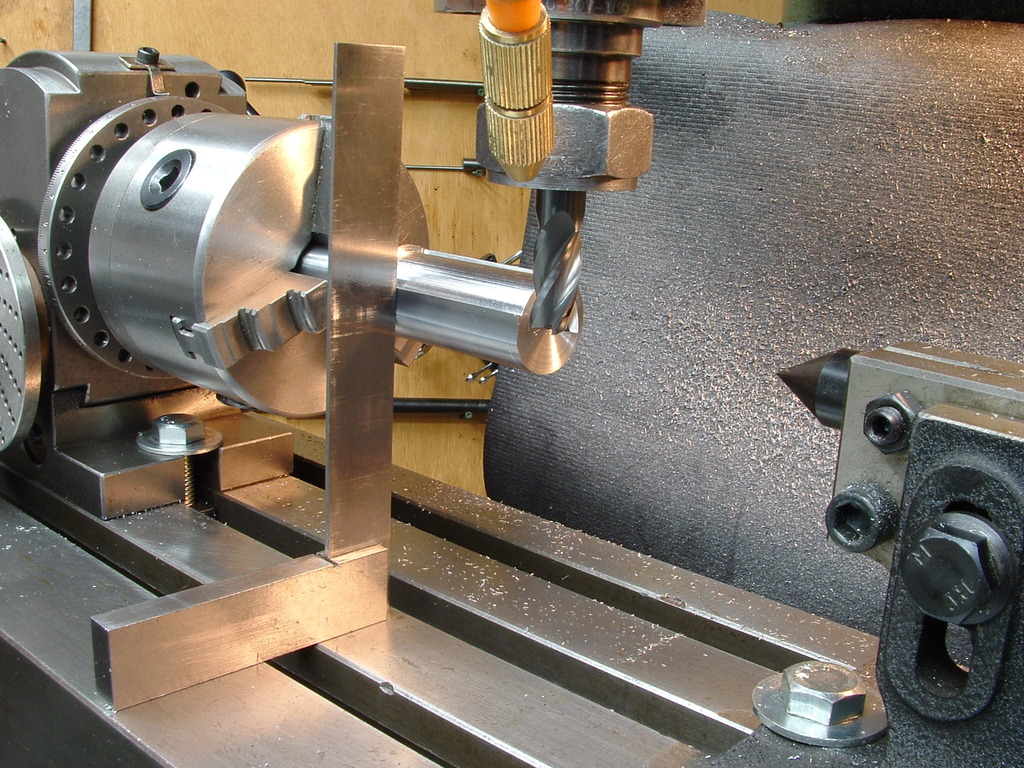

Now, we can discuss the profiling of the barrels and the prototype machining I did on barrel breech end "mock ups". As I stated at the outset of this post, I had no experience in building or knowing how to build shoe lump barrels, and as a result I "thought" through the process of how I could do it for about 3 months. As I viewed the 2-3 methods that I conceived in my mind of how I could make a set of shoe lump barrels that would fit the donor zp49 action I had at hand, I settled on the method of building a shoe lump platform that I have illustrated above.

However, I did not want to risk the use the set of barrels that I had profiled from 1.120" round rifle blanks, to learn if my ideas proved to be correct or wrong. Therefore after I had profiled the barrels, I set about machining the mock up breech ends to determine how many degrees of the 360 degrees of the outside diameter of the barrels I must cut away to fit the shoe lump platform. This is illustrated in the photos below.