| transvaal |

| (.300 member) |

| 28/03/17 12:08 AM |

|

|

You will notice in the photo of the above post that the action face shows the original shotgun firing pin (striker) discs that are threaded into the action face. These discs were replaced with two discs that I made from 0-1 alloy steel, with reduced diameter firing pin hole suitable for high pressure rifle cartridge as well as the 3 holes for the removal/installation tool to fit into. I reduced the 3 mentioned holes to the size of a #50 drill; and the reason for this reduction was that I wanted to make sure that the 3 holes were outside of the primer zone when the rifle was fired. The correct position of 120 degrees apart for the 3 holes was accomplished using a rotary fixture mounted vertically on the table of my vertical mill. After building these discs of 0-1 alloy steel they were hardened and tempered. Small item but could cause big issues if not put right in building a DR.

You can also see the hidden third fastener slot in the face of the action. We can discuss this later for any of you who wish to, but suffice it to say now that the third fastener fitting should be the final item to be fitting when jointing the DR barrels to the action. I like third fasteners of this type to be fitted to where they will hold the action closed to the same position as the action horizontal locking bolt. They should be made and fitted so that as the DR recoil wears the barrel extension over the years a new third fastener of thicker steel can be made and inserted in the slot without enlargement of the slot.

I think this is a proper time in this narrative to discuss that all double gun actions are not made to exacting tolerances and that each one should be checked for the squareness of the face to the lump slot that is milled into the water table of the action. This slot is the data point from which all dimensions and measurements of the action must be taken.

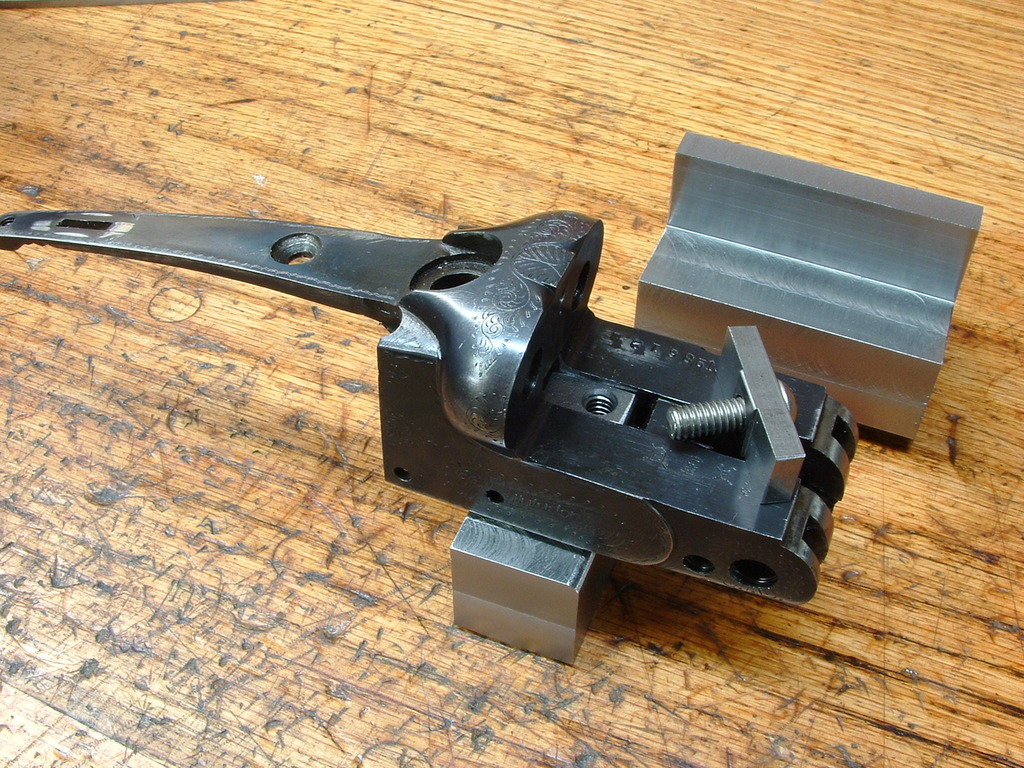

The first measurement that should be checked: Is the face of the action square (perpendicular)to the water table lump slot? (You will be surprised at what you find if you do this test) In order that this test can be carried out with a high degree of accuracy a fixture must be made that holds the action securely without any movement so that the fixture with the action attached can be mounted on a vertical mill and a dial indicator used to measure deviation from zero right to left and left to right of the face of the action. You cannot mount a double gun/rifle action with 100 % assurance that it is mounted square in all directions without such a fixture. The photos below show how to make the fixture.

The fixture is made in a vertical mill and is machined square in all directions. A portion of the fixture is milled to exact width (less .001" of the individual action's lump slot, as the action is to be attached via this portion or extension of the fixture.