| transvaal |

| (.300 member) |

| 27/03/17 02:22 PM |

|

|

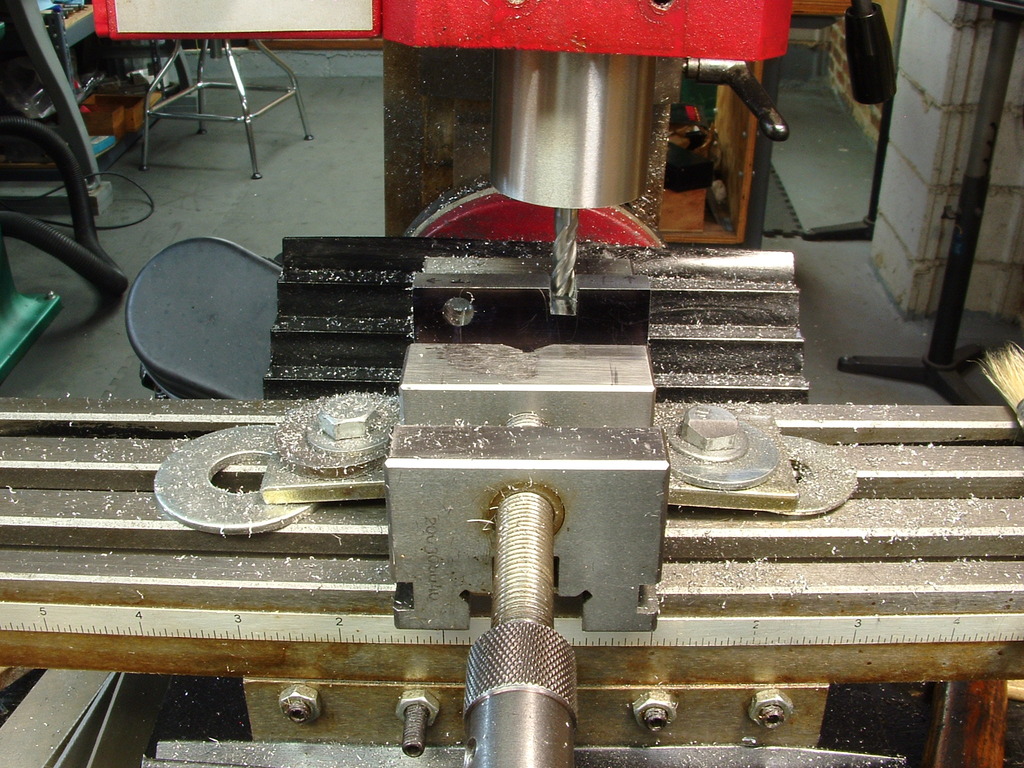

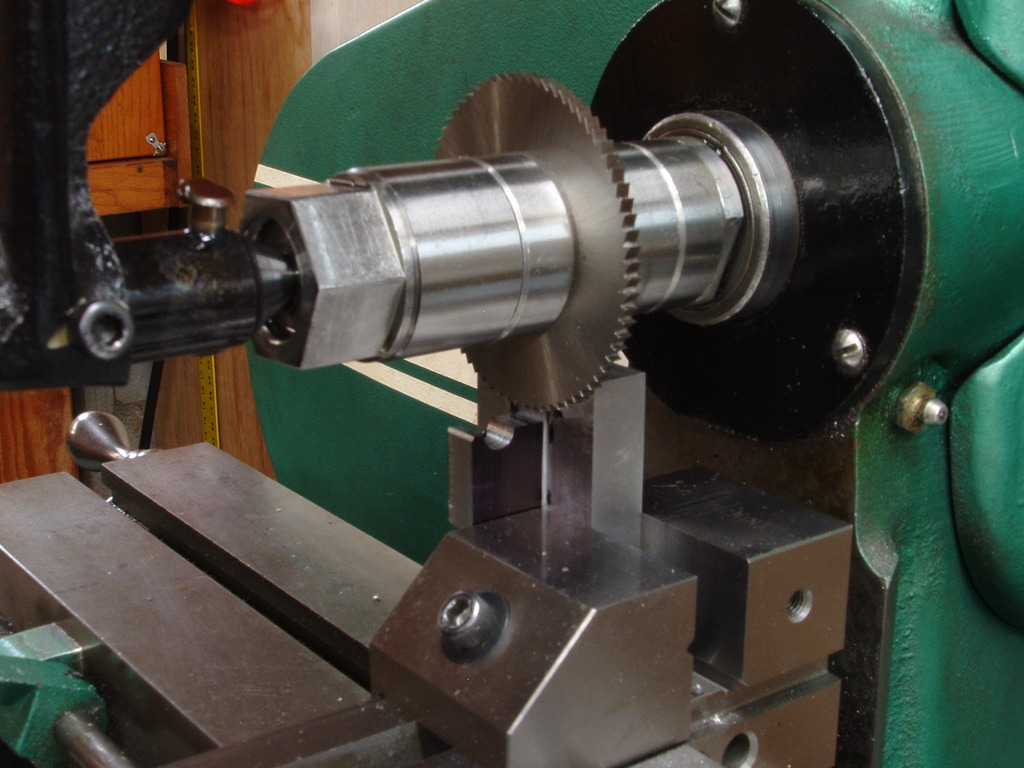

The machine cutting away of a radius (1 inch) to the right/left top of the shoe lump platform is accomplished by a 1 inch ball tip milling cutter as illustrated in the photo below. You can also set the angle of the barrel convergence so that the radius "channels" are correctly positioned for the amount of convergence you desire. If you cut your channels to deep (and too deep can be only a few thousands of an inch, you will have to discard the shoe lump platform that you have spent much time and effort and make a new replacement. I picked 1 inch as my radius after much careful consideration and measuring to have the proper fit and jointing of the barrels.

After you have finished the total machining of the shoe lumps, including cutting the angle of the front of the rear lump to mate at a hard fit with the action draw, you can began to hand joint the platform to the action prior to brazing the barrels to the shoe lump platform. Much of the fitting and jointing will be done with the hinge pin removed from the action. Later I will explain how this is accomplished by leaving material at the top of the forward lump hook. If I forget to explain it remind me of it.