| transvaal |

| (.300 member) |

| 27/03/17 01:55 PM |

|

|

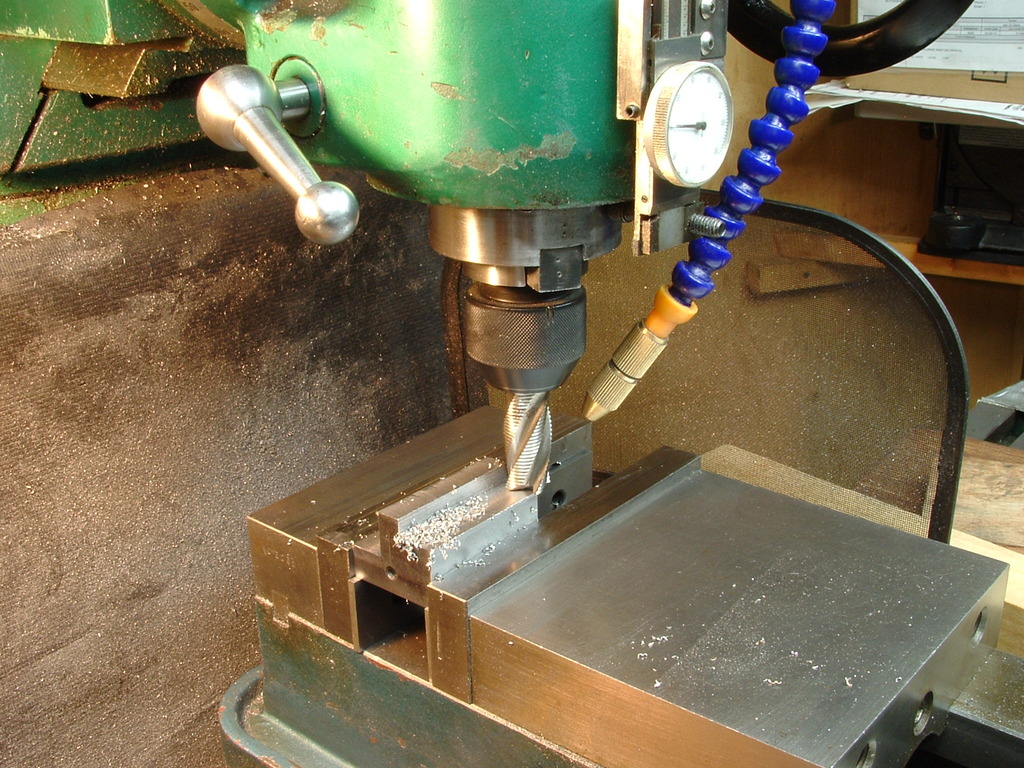

Continuing the posting of photos of machining the shoe lump platform.

It occurred to me earlier tonight as I was waiting for Photobucket to regain its operational ability, that I should show you some photos of what the final shoe lump product looks like and how it is positioned on the barrels prior to brazing all together. Then you will understand where we are and where we are going on this posting.

In the photos below you will see photos of the machining of the lumps. You will also see photos of the contured barrels after I spent a week or so getting them down to the weight and profile that I wanted. The diameter of the barrels at the muzzle is .575" and they weight a bit over 2 pounds each. Most importantly you will see how I devised a way to cut away a radius section of the bottom of the barrels to fit the shoe lump platform. This cutting of the radius is the solution to having the barrels breech end exactly centered to the firing pin bushing holes (striker discs holes) while at the same time leaving about .075" minimum shoe lump radius under the barrels for proper service strength and brazing area. It is extremely important to calculate this machining of the radius and the fitting to the lump exactly to withing a few thousands of an inch, so that when the action is closed you have sufficient gap between the barrel flats and the action flats.