| Setterguy |

| (.275 member) |

| 16/01/13 09:57 AM |

|

|

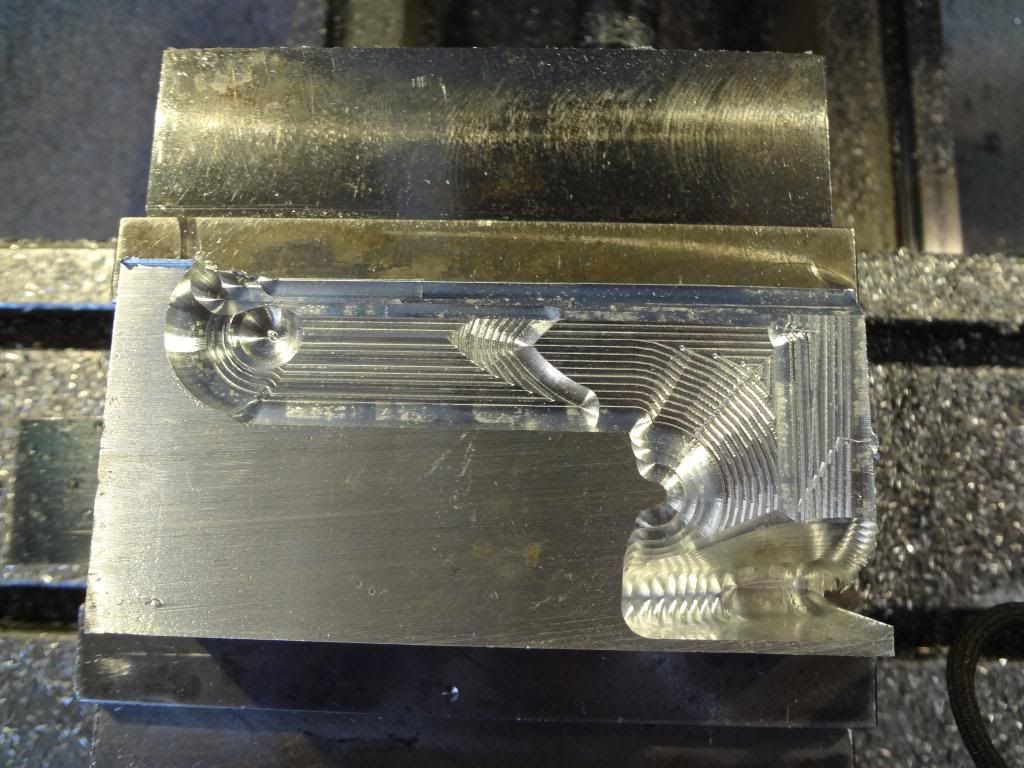

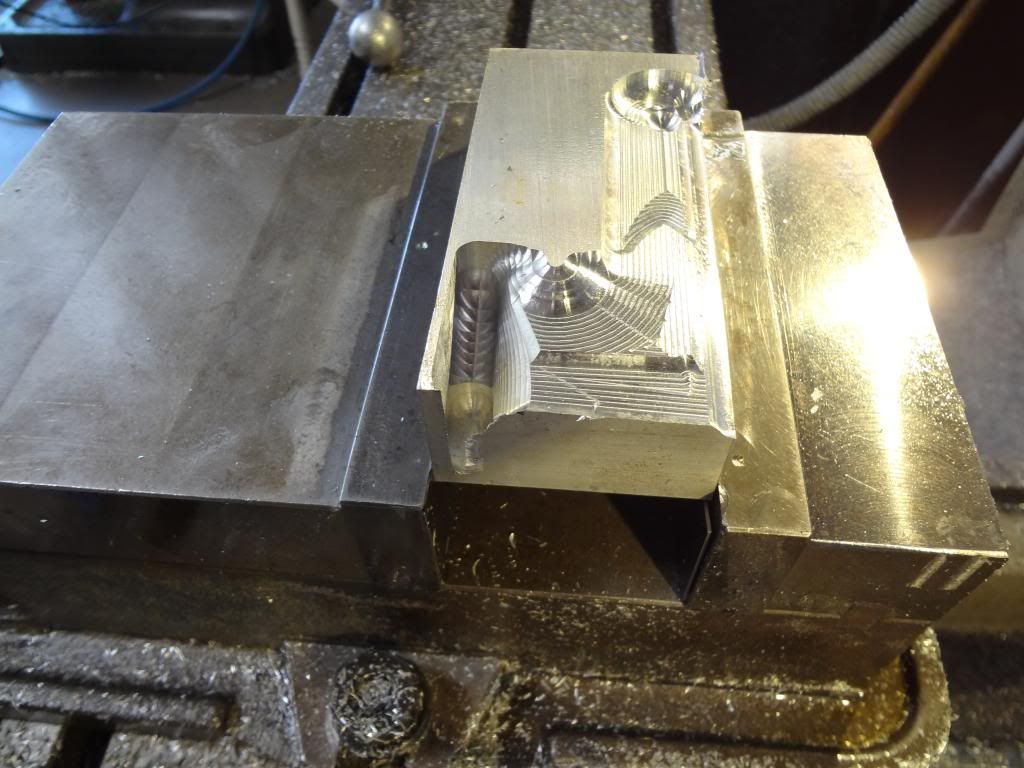

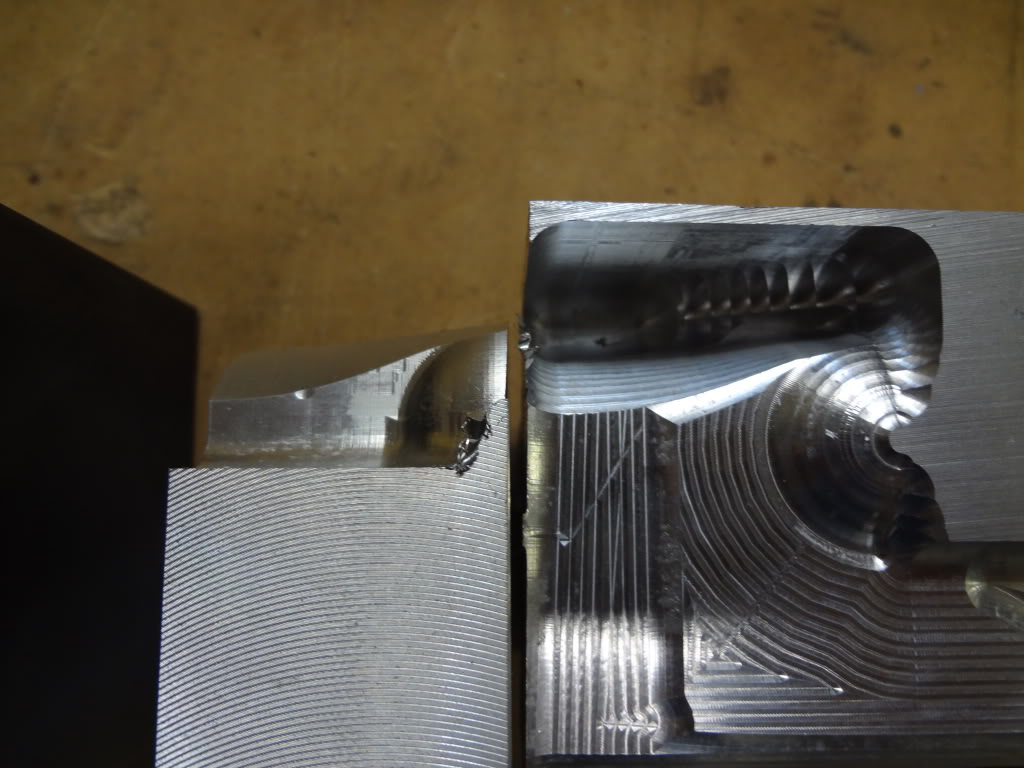

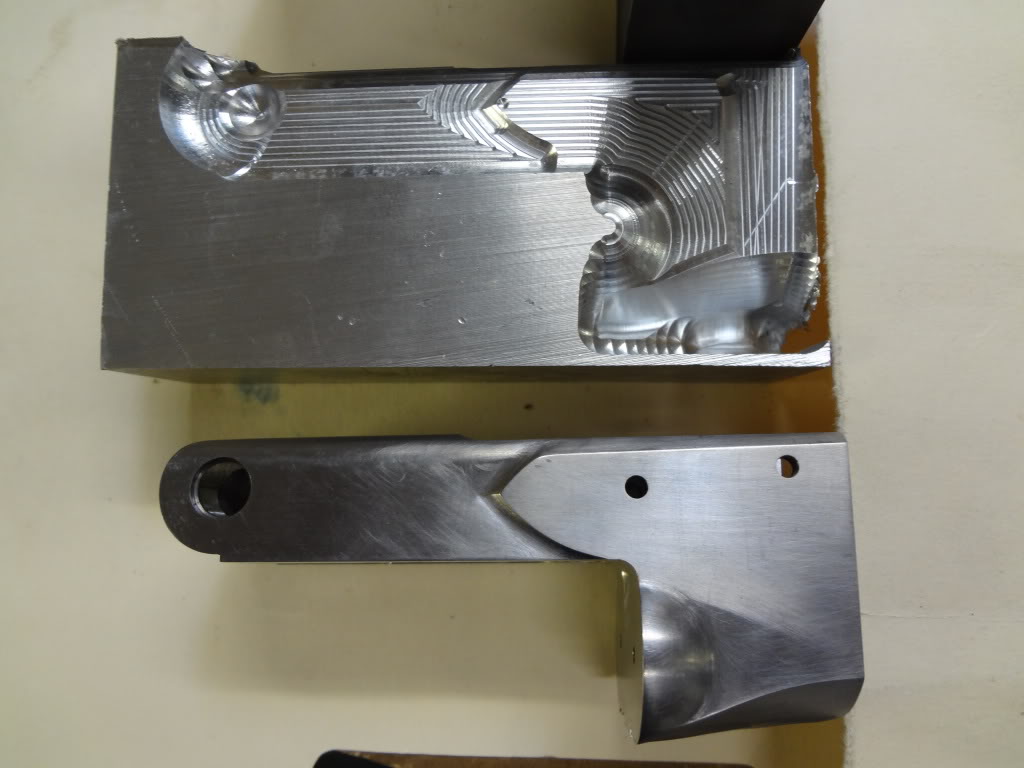

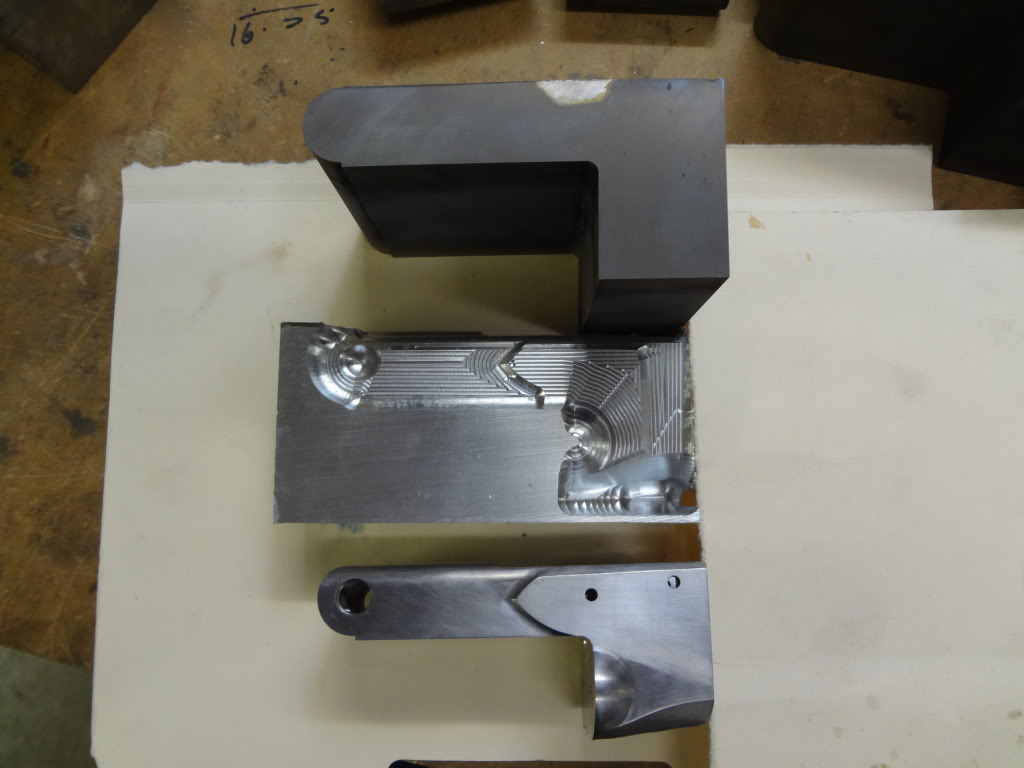

I promised to show some photos for the validation process of using the CAD data in the CAM milling machine. After cutting the receivers from the blocks of steel and titanium we needed to see if the program would accurately reproduce the all the outside contours of the receiver. We used a block of aluminum to start this process in order to not ruin one of the actual receivers. It was a good thing too since we did have a problem as discussed above. Below are some pictures of the outcoume.

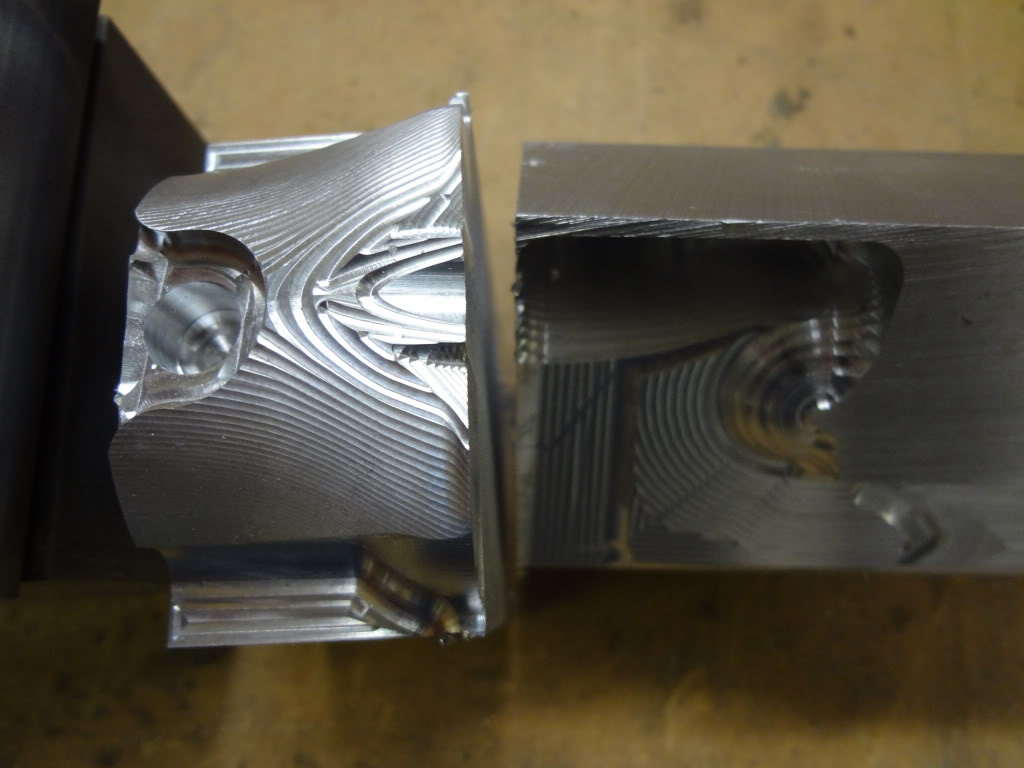

You can see that the receiver contours are going to be correct and the dimensions accurate. As you can see from the next series of pictures the receiver is taking shape.

As I have said in other threads there really is no shortcut to this process. Each step must be validated and verified. I have now begun the actual milling of the 4340 steel alloy receivers. I should say that the two dimension milling of the insides of the receiver are more straightforward than the complex radii of the surface. I will post progress as I hopefully make some.---Bill