| Ron_Vella |

| (.333 member) |

| 27/07/12 03:30 AM |

|

|

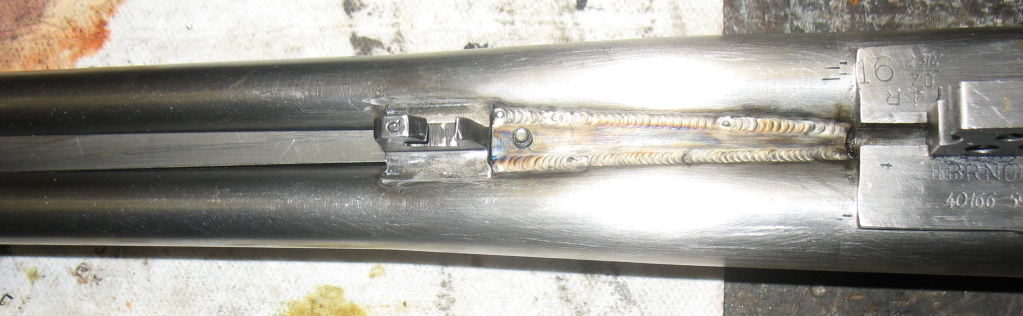

Rather than use a very thin filler rib behind the forend hanger, I filed one up out of stock that was about .100" thick. Yesterday I took it to the "welding magician" and had him TIG it into place. Then I drove over to my tool and die maker friend's house and we set it up in the Bridgeport mill in his garage. We were then able to drill, counterbore, and tap near the front of the quarter rib, for an 8-40 screw, which fastens into the filler rib. This gives me two hold-down screws, the other goes into the original top rib extension. The rear screw will be hidden under the rear scope base. The front screw will be hidden under the rear express sight base. I find that doing the job this way really simplifies the job of soldering the ribs on. Everything is "dead-nuts" square and true and it's impossible for the assembly to shift during the soldering process. Here are a couple of photos showing the "rough-in":

Today I spent a couple of hours with a small grinding head in the Dremel tool, then with progessively finer machinists' stones, polishing down the welds, while the area was flooded with Varsol. Then I drilled and tapped a 6-48 drain hole and installed a plug screw. Here are a couple of photos of where I'm at now:

More to come.