| 450_366 |

| (.400 member) |

| 30/01/10 10:13 AM |

|

|

|

|

Almost a year has past and between my family and our house, together with some other projects, this one had to wait. But i had time to gear up a bit for the build in the meantime.

I did get some time the last week and at least got something done.

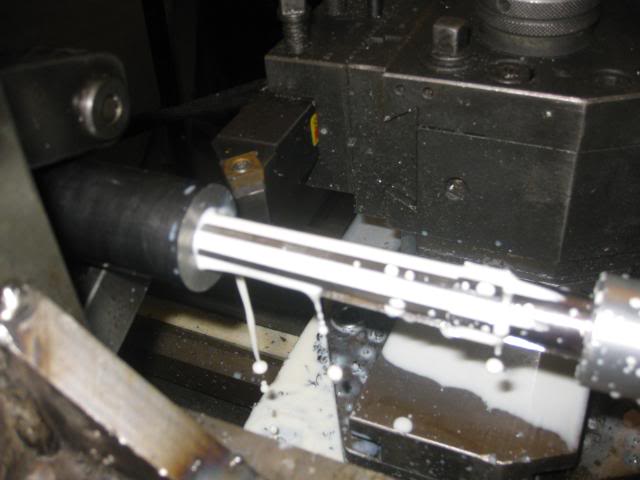

To be able to give the barrels a nice contour i added a hydraulic copy device to my old lathe.

Here i start with taking the shotgun barrels profile and add a cylindrical peace over the chambers, some filing and stonig and it seems to be satisfying. It tapers rapidly in front of the chambers from 28,5mm, untill it reaches the end of the forend at 19mm diameter.

To be able to turn the barrel i had to get one of these.

Its a hydraulic steady rest that i searched for almost a year to find, and then it was in the US. Here around they are not hard to find, but if i did find one it costed as a car or it came with a cnc lathe attatched.

Last time i chambered a barrel it took ages, and i had to reverse the reamer every tenth of milimeter to get the f....g chips out. So i had to do something before i did it again.

I took a peace of aluminium and a couple of bearings and presurised the lathe with cooling fluid.

Together with a peace over the end of the barrel so it sealed up inside the lathe it worked quite well actually.

The next thing to do is to profile the barrels from the dummy i made. Then its the matter of the lump, first i intended to mill it, but that sounded quite boring so there must be an alterative.