| baileybradshaw |

| (.333 member) |

| 28/08/09 12:27 PM |

|

|

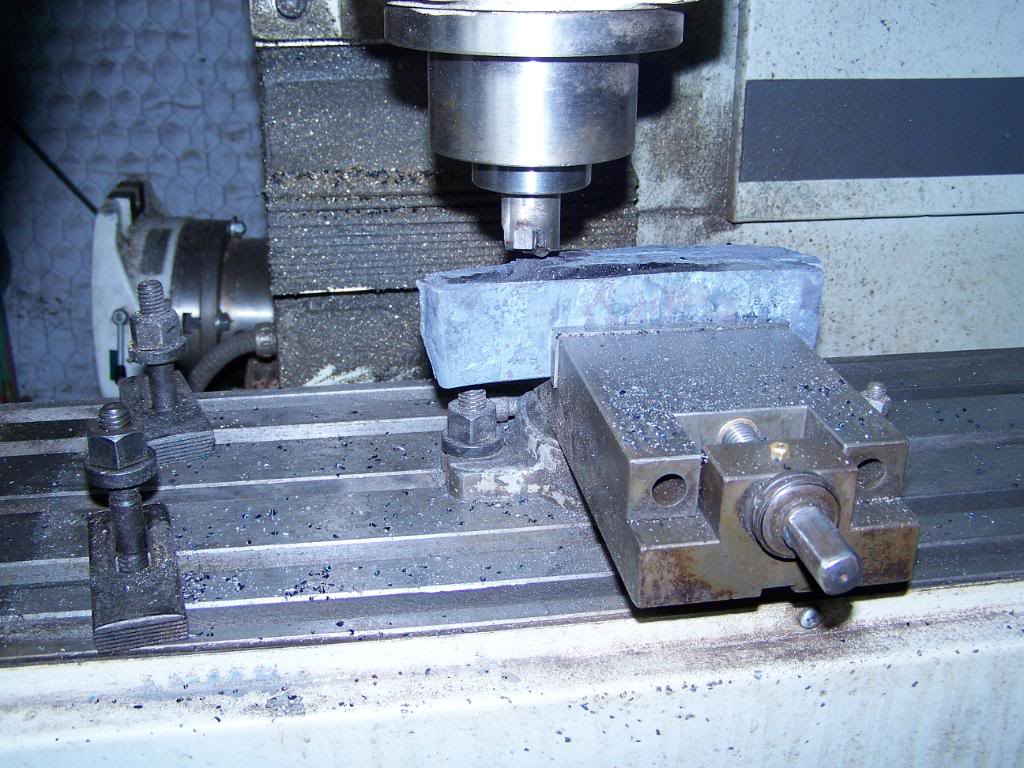

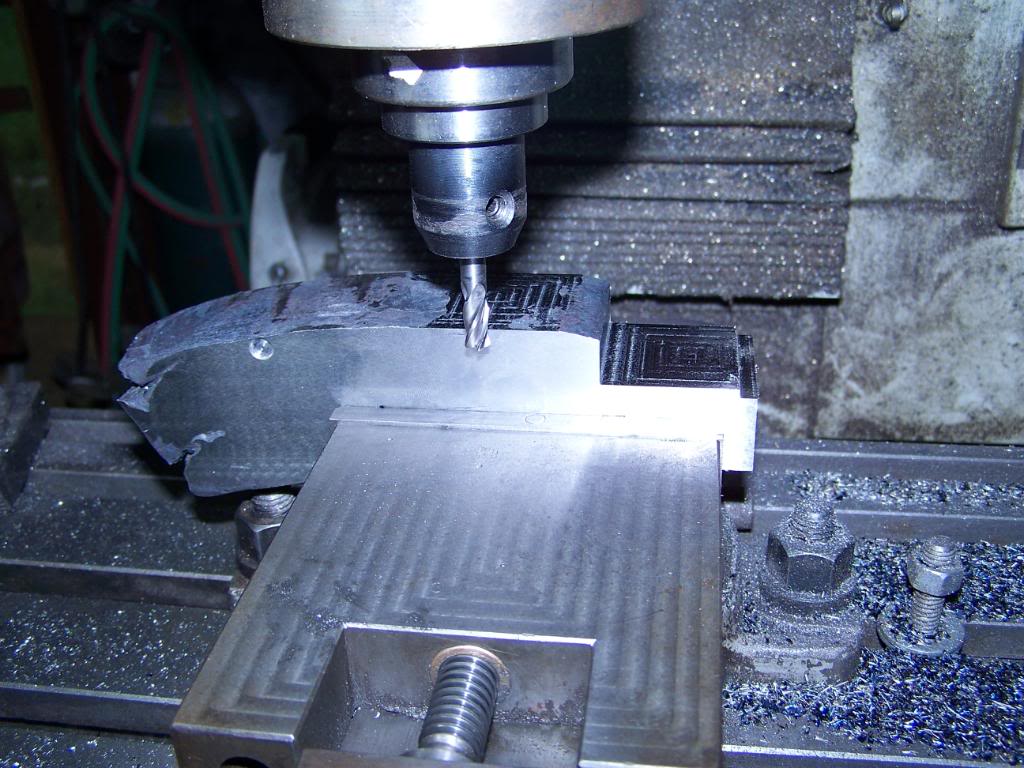

After the rough forging, obviously the billet needs to be flat on the sides and squared. The scale and slag on left from the forging is very hard, and eats grinding belts, so I fly cut the majority of the scale off.

Next I surface grind the sides to ensure they are a flat and parallel as I can get them. This is critical as it is the foundation for the precision of the work yet to come. It also allows me to square up the critical areas of the action where I will take measurements from for locating holes and orienting the billet on the wire EDM.

The next step is to anneal the billet to relieve forging stress and refine the steel's grain. Fine grain dramaticly increases toughness, so it is paramount.

I did a quick etch of the action top to show the damascus pattern before going into the furnace.