| alexbeer |

| (.333 member) |

| 24/02/09 10:44 PM |

|

|

|

As promised ladies and gentlemen, some photos on the brazing of a shoe-lump.

This one is a new set of barrels for a Westley Richards 500NE.

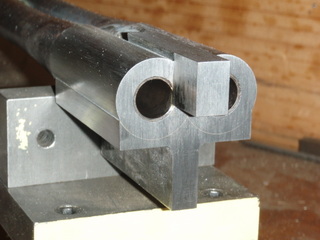

The initial fitted pieces

Fit and alignment double checked (the barrels are chambered to approx .030" short)

Totally cleaned, fluxed and bound together, with the silver braze wire laid on the top only ( I hope you can see it there) Anti scale paste has been applied to the chambers and the first half of the bores.

In the furnace, getting up to just over 650C (1202F) the flow temp of the braze

Out of the furnace after cooling, a bit ugly but it will clean up fine

In these last two you can see (after a quick clean-up) the silver braze has gone through the entire joint. Remember the silver braze wire was only laid on the top of the assembley. Once the assembley was up to the correct temp, the braze melted and capillary action drew the braze right through the joint.

Now all I have to do is clean it up properly, fit it to the action, fit the dolls head, bore the hole for the extractor leg, form and fit the extractors, deepen the chambers and set the headspace, form and fit the fore-end loop, the spacers, the wedge assembley, the ribs, put it all together and regulate it.

Dosn't sound like much if you say it fast, does it?

Dosn't sound like much if you say it fast, does it?Regards

ALEX

www.alexbeer.com