| baileybradshaw |

| (.333 member) |

| 25/08/09 11:46 PM |

|

|

One of our brothers here on NE ordered this rifle. I mentioned I would like to do an "in-progress" thread, and he agreed.

So, here is what I will be making for him. One of my doubles chambered in 22 hornet, exhibition English walnut stock, quick detatch scope rings and......drum roll please...damascus action.

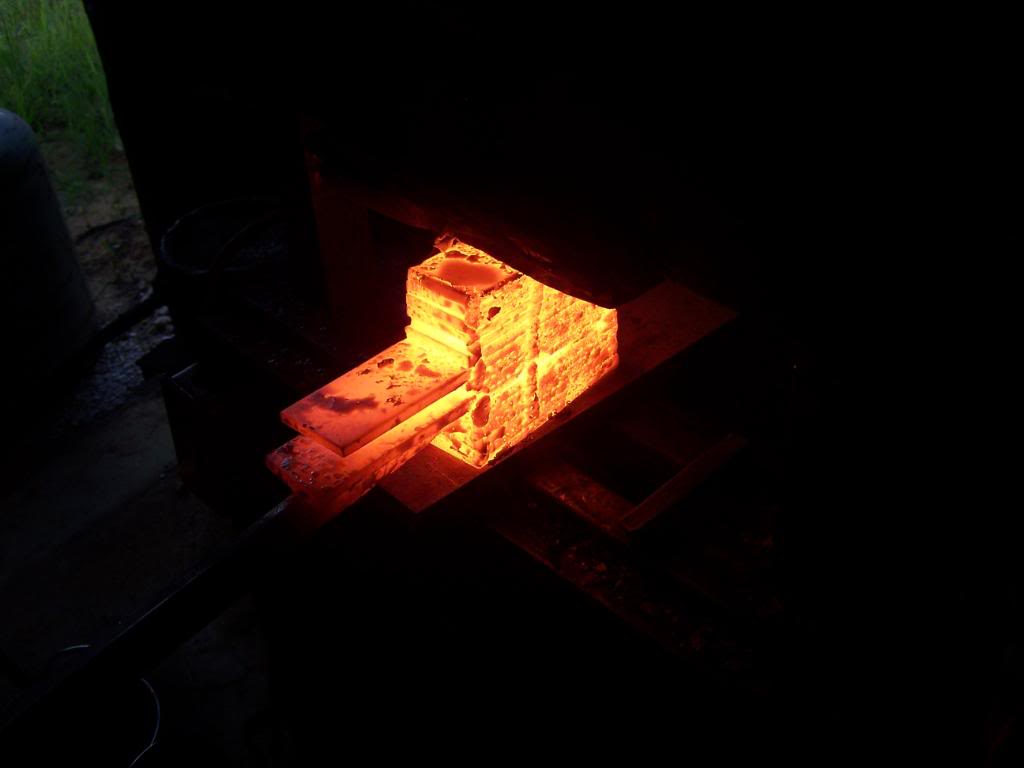

To start with, here are the raw materials.

The damascus billet starts with 16 layers of 1075 and L-6. Both steels have .75% carbon, which is high for a typical rifle action. Through the forging process, the steel will loose. .1 % or so of carbon. I know my heat treating on these steels very well, and will end up with 40rc hardness.

so, into the forge we go. It's a large billet, but won't yield enough for everything, just the action. I will forge another billet for the top lever, trigger group and forend iron.

After it gets hot enough to melt the flux ( borax), it recieves a coating. This will allow the steel to stick by keeping an oxygen free enviornment at the weld joints.

Squeezing for the first weld. I use a hydraulic press with 24 tons of pressure to forge, as well as my Grandfather's 25lb Little Giant power hammer.

Once I get the first weld complete, which takes 2 or 3 weld cycles for insurance, I begin to draw it into a long bar.

And finaly, the bar drawn enough to cut into five pieces, restack and forge weld together. This will give me 80 layers, the next cycle of weld, draw, cut and stack will give 400 layers, and finaly 2000 layers. That is a high layer count, but given the thickness of the action, it will take that many layers to create the surface effect I want.

Since I just can't resist, a shot of the stock blank.

A couple more notes on the damascus. It will be a random pattern, but each layer will run the length of the action. The result will be a tight wood grain effect. The L-6 has 2% nickle and remain bright once the steel is etched with acid to reveal the pattern. The 1075 will etch deeper than the L-6, and once polished after the etch, it will create a sort of holographic shimmer.

More to come......

| kamilaroi |

| (.400 member) |

| 25/08/09 11:52 PM |

|

|

far out Batman!

| peter |

| (removed) |

| 25/08/09 11:57 PM |

|

|

|

bailey

i know the gentleman, that you are making it for, and he is very fortunate to be getting this kind of craftmanship in his rifle, please keep up the blow by blow, it reminds me that my own forge is chatching cobwebs at the moment (18 months worth) actually.

best

peter

| Mike_Bailey |

| (.400 member) |

| 26/08/09 01:59 AM |

|

|

Wooooooooooooow ! best, Mike

| baileybradshaw |

| (.333 member) |

| 26/08/09 05:02 AM |

|

|

Peter,

Don't let that forge lounge for too long...No stress releiver like pounding steel :-)

Now for more progress...

Here the bar has been de-scaled and marked for cutting

Blocks have been cut and ready for stacking and welding

Here the stack is assembled and all the joints welded closed for dry forge welding. I don't do this on the first weld as there are so many seams to weld closed.

And the bar drawn out once again, ready for cutting and stacking.

| 500Nitro |

| (.450 member) |

| 26/08/09 05:10 AM |

|

|

Superb.

It's good to see the old skills still in use today.

Well done, should come up a treat.

| VonGruff |

| (.400 member) |

| 26/08/09 06:53 AM |

|

|

There are a lot of superlatives that have been used and will be used as this build progresses but I want to express my gratitude that you (and to whoever has comisioned this work) are prepared to take the time to give us this addictively interesting step be step LOOK at the proceses that most of us would never see otherwise. You know that this is the first place we will visit every morning to keep up with each new step. Sincerely, thanks.

Von Gruff.

| 450_366 |

| (.400 member) |

| 26/08/09 08:12 AM |

|

|

|

|

What else to say than really impressive, this one will be great fun to follow.

| Oldsarge |

| (.300 member) |

| 26/08/09 04:23 PM |

|

|

|

What an extraordinary idea. A Damascus action. Innnnnnnteresting!

| michaelj |

| (.224 member) |

| 27/08/09 07:35 AM |

|

|

Simply outstanding. I look forward to the progress postings.

You Sir are very talented and very generous with your knowledge.

Thank You

Michael J

| vikram |

| (.300 member) |

| 27/08/09 07:49 AM |

|

|

That is an extremely interesting effort and I can appreciate the effort going in.I know that it's too much of an effort, but why not Damascus barrels too? Just curious.Thank you for sharing.

Best-

Vikram

| baileybradshaw |

| (.333 member) |

| 27/08/09 10:31 AM |

|

|

Thanks for the kind words Gents. I am glad you will keep watching and should enjoy this build.

Vikram,

I am working on the damascus barrel idea. I have the idea to forge the barrels with a solid 4140 core that would then be drilled and rifled like a conventional barrel. I have discussed this with several of my damascus making friends and have one man in particular that is more talented than I in the fire. He is ready to try it once we have someone with the desire to own the piece. Shane Taylor is his name. He specializes in damascus making and makes a lot of mosaic steel where an image is actualy forged into the steel. his website is www.taylorknives.com .

A little 22 hornet with damascus barrels and mosaic damscuc action with pictures of hornets in the steel..... Would be a VERY interesting piece.

I am sidelined with a bug today, but am feeling better and will have another update tomorrow.

Thanks again!!

| vikram |

| (.300 member) |

| 27/08/09 10:40 AM |

|

|

Bailey,

Thank you for the informative reply and the privilege of watching you build this. I would certainly be game for a damascus actioned and barrelled DR.I just have to wait till I win the Euro Lotto.Sigh...

All the best with your projects.

-

Vikram

| baileybradshaw |

| (.333 member) |

| 28/08/09 05:05 AM |

|

|

OK, I have the rough forging complete. The billet is at 2560 layers. This sounds like a lot, but consider the average 1/4" thick knife blade in damascus has a nicely balanced pattern ( not too course, not too fine) at 340 layers. This action blank in the rough measures 1.8", equal to just over 7 blade thickness, for an average layer count of 350 per blade thickness. 2560 layers should look perfect.

First picture if just the billet and a side project coming to weld temp in the forge. Ever heard the phrase "too many irons in the fire"?

Here is the billet at 320 layers ready to grind clean and cut and stack for 1280 layers.

And the stack welded together and ready to go into the forge

I failed to get a picture of the last welding process. I drew the billet out to about 8" long, and hot cut it in the milld leaving about 1/4" uncut. Then fold it back and tack weld the end, then into the forge and make it all one. I squeeze the end that will make the action bars for a couple of reasons. One to help maximize the billet, and to get the pattern to flow from the action bars to the standing breech.

Here is the rough damascus billet ready to clean up.

More later today...

| baileybradshaw |

| (.333 member) |

| 28/08/09 12:27 PM |

|

|

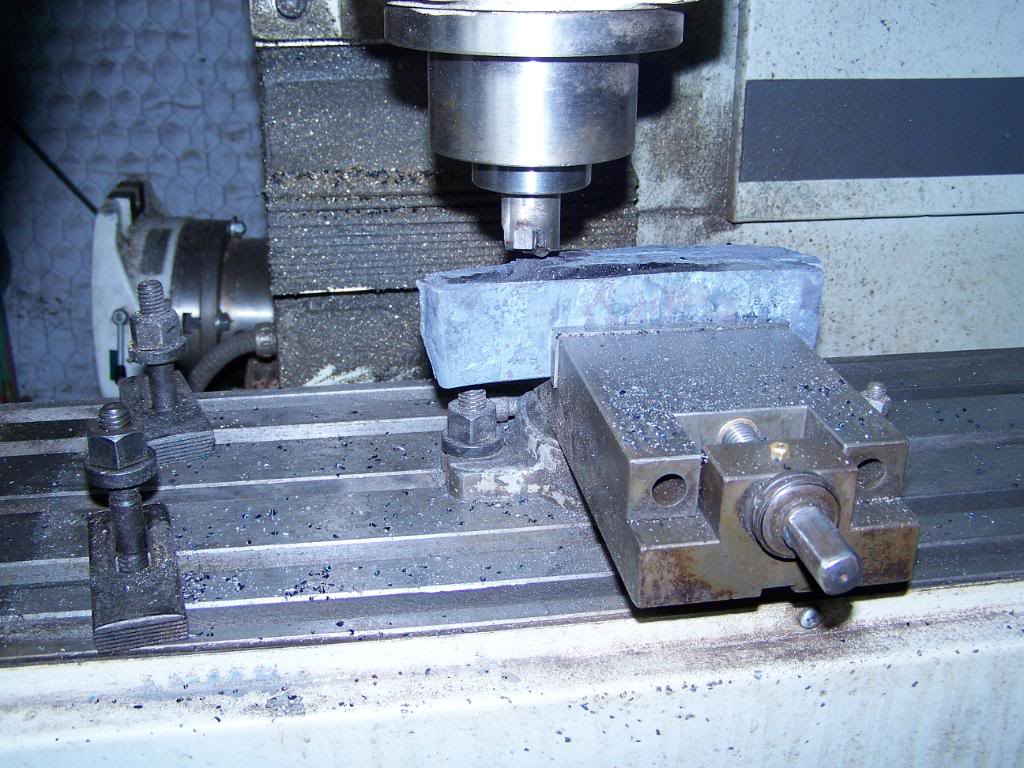

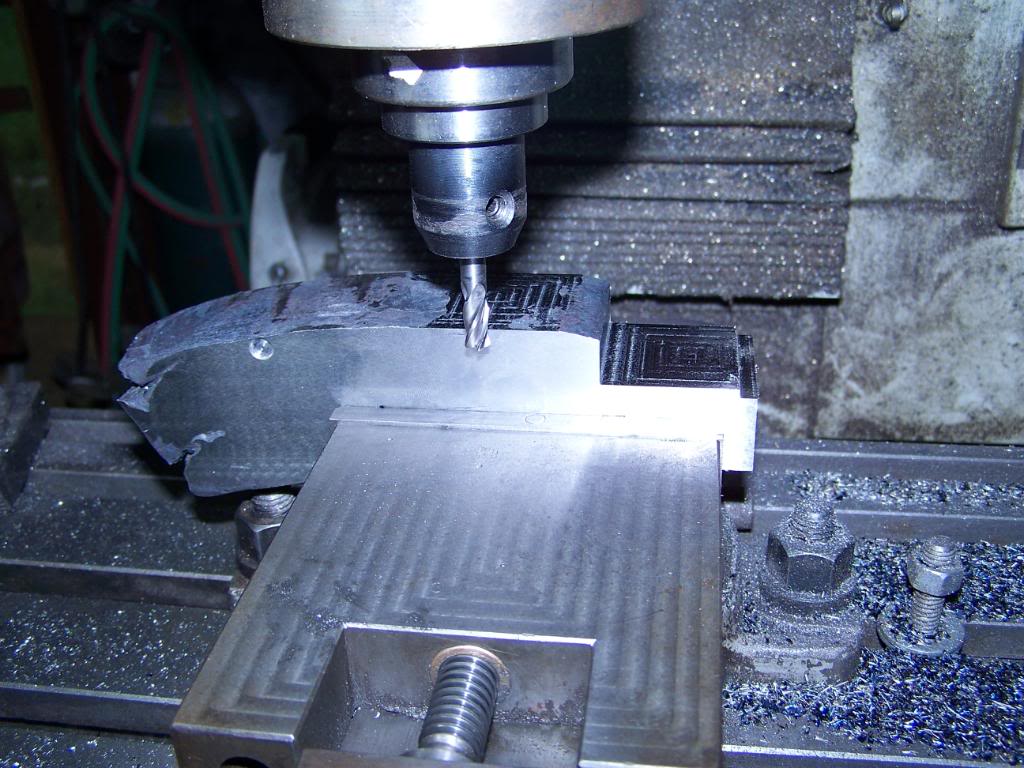

After the rough forging, obviously the billet needs to be flat on the sides and squared. The scale and slag on left from the forging is very hard, and eats grinding belts, so I fly cut the majority of the scale off.

Next I surface grind the sides to ensure they are a flat and parallel as I can get them. This is critical as it is the foundation for the precision of the work yet to come. It also allows me to square up the critical areas of the action where I will take measurements from for locating holes and orienting the billet on the wire EDM.

The next step is to anneal the billet to relieve forging stress and refine the steel's grain. Fine grain dramaticly increases toughness, so it is paramount.

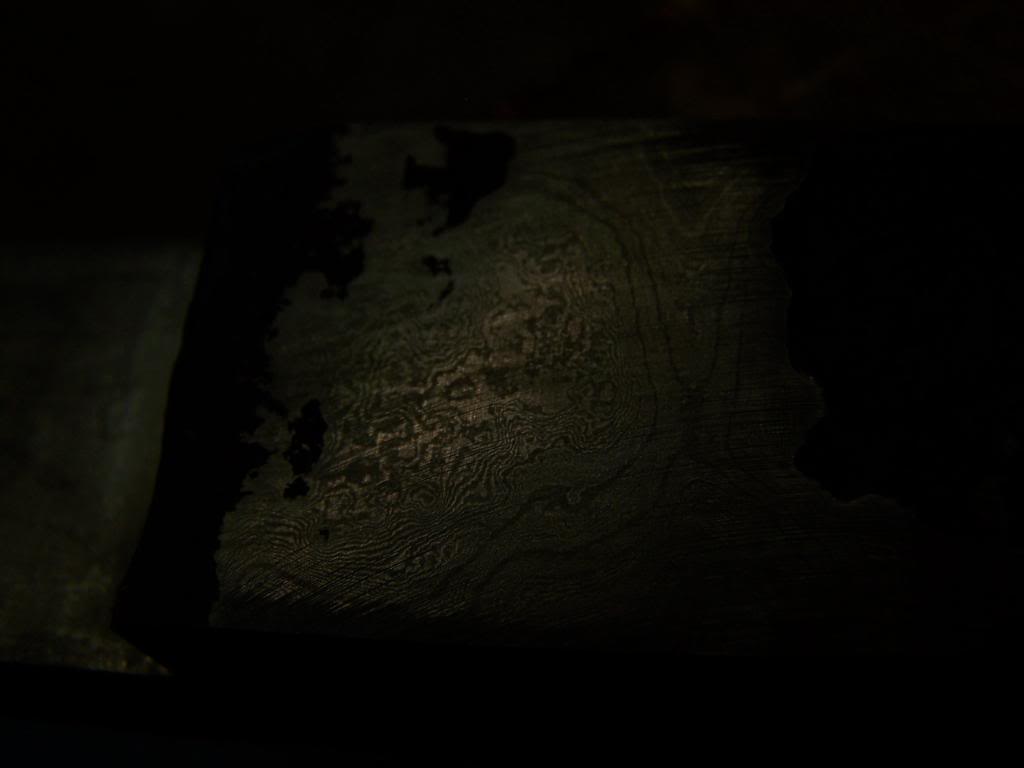

I did a quick etch of the action top to show the damascus pattern before going into the furnace.

| mehulkamdar |

| (.416 member) |

| 31/08/09 02:36 AM |

|

|

|

Very, very nice work! This should be a real beauty to warm the heart of whoever owns and hunts with her!

| baileybradshaw |

| (.333 member) |

| 31/08/09 09:01 AM |

|

|

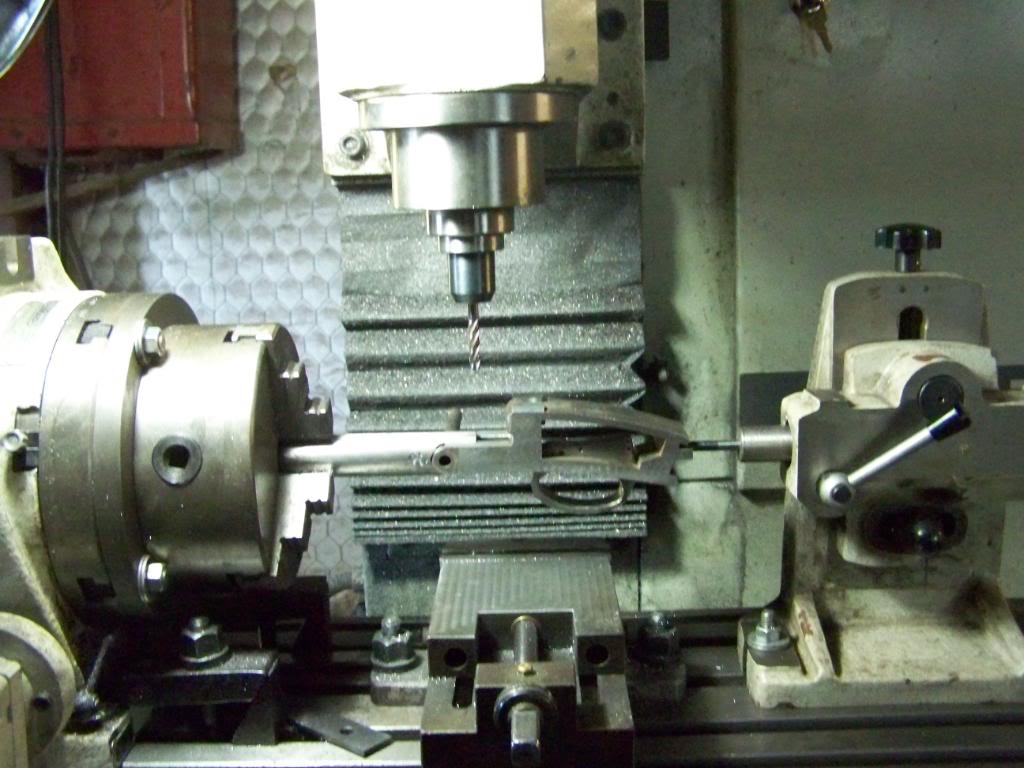

OK, With the billet annealed, I need to locate and drill two starter holes for the wire EDM. I use an edge finder to locate the center of my wrist pin hole, which is X0, Y0 (remember basic geometry from school)for all operations from this point on. This is just a starter hole, and will be opened up with the EDM. Drill the wrist pin hole, then move to the tang cavity starter hole and drill it as well.

The billet is then loaded in the wire EDM, and useing the same method as the edge finder on the mill, I find X0, Y0...the center of the wrist pin.

Once I have that location, I thread the wire through the cavity starter hole and make the cut. Here is a picture of the program path on the EDm screen.

I would shoot a picture in the EDM work area, but you would only see water spray everywhere. EDM stands for electrical discharge machining. It works like and arc welder in reverse. The machine uses a .010" brass wire, with fresh wire being constantly feed through the work, with an electric charge, which causes an arc between the wire and the work piece, to erode the metal in front of the wire. The wire never touches the work, but maintains about .001" gap. It is VERY accurate, but VERY slow.

Once I cut the tang cavity, I clean up the wrist pin hole in a spiral path. Produces a better hole than a drill and reamer, and since the rest of the profile of the action will be cut next, the hole will be perfectly parallel with the action face.

| baileybradshaw |

| (.333 member) |

| 31/08/09 09:14 AM |

|

|

While waiting for the EDM, I precut the stock blank for machining. I left it oversized of course, but it sure shows how the layout runs. I rough machine the exterior of the stock on my 4 axis mill, as well as the inletting. The inletting saves about 10 hrs of work.

Back to the EDM, here is the tool path for the action breech top and bar.

I also have the damascus forged for the trigger group. I wanted the pattern to show on the sides of the housing, and on the bottom of the trigger guard. I used 3 pieces, and turned the center bar 90 degrees.

Since the trigger guard is centered, the damascus pattern will show. The billet has such a high layer count, that the edges of the billet don't show, as the layers are too fine unles there is enough surface area to show some movement.

Here is a picture of the pattern that will be the sides of the trigger housing.

| baileybradshaw |

| (.333 member) |

| 03/09/09 11:48 AM |

|

|

Moving ahead....

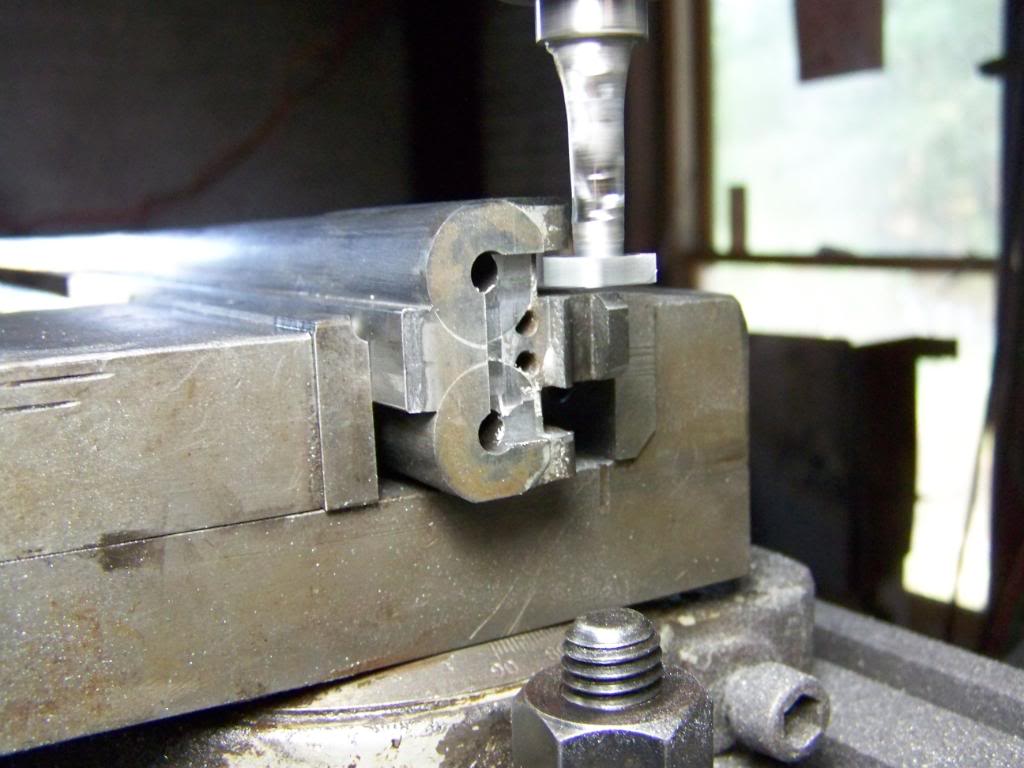

Her is the trigger housing billet being profiled on the mill.

The trigger guard and bottom surface will be finish machined with the action, so those areas are left oversized for now.

And the part profiled and the holes spotted and drilled as well as the front end machined with the "tounge" that secures the housing in the action.

I am working on two other rifles at the same time, I had a delay from my steel supplier getting the 8620 bar to me. It arrived Monday, and here is the first forging.

It's a 2 1/2" round bar, and forging this big stuff makes me want a larger power hammer.

Now back to the rifle in question....The action body is off the EDM and is ready to start machining. We added side clips, which I like and they should add a lot to the appearance of the action. Here are all the parts so far.

In the last fold I made when forging the damascus, I added 5 layers of steel that were full thickness, like what I started with. It produced the stripes in the center of the action shown here.

They run the length of the action and show on top and bottom.

| 333Jeffery |

| (.300 member) |

| 04/09/09 05:04 AM |

|

|

I'm curious about the EDM process. Why do you use it, instead of just milling the parts with regular machinery? How long does it take the EDM machine to carve out the action? Thanks.

| 500grains |

| (.416 member) |

| 04/09/09 06:14 AM |

|

|

|

Amazing set of photos. THank you.

| baileybradshaw |

| (.333 member) |

| 04/09/09 12:12 PM |

|

|

I use the edm for a couple of reasons. First is it is HIGHLY accurate. It is slow, but the finish and accuracy is the tradeoff. Second is it's ability to cut complex profiles with one setup. If I used a machining center, I would have several tool changes and expensive cutters, and probably more than a couple of setup changes. There are a lot of potential problems and loss of accuracy issues. The accuracy of the EDM allows me to cut the separate parts that will fit together near perfectly with minimal polishing of their mating surfaces.

| baileybradshaw |

| (.333 member) |

| 12/09/09 12:04 PM |

|

|

I have the fortune of being selected to make the knives of the year for Sporting Classics magazine, and have been getting the prototypes made for them, so it has interupted my time on the rifles.

The knives are almost complete and I have been getting some work in on the guns. I will post the update in the next day or so.

Thanks!!

| baileybradshaw |

| (.333 member) |

| 15/09/09 10:48 AM |

|

|

OK, finaly have an update ready. I buy mt barrels as blanks at the moment, so I have to machien them down to profile or have a local machine shop do it for me. I machined these on my 4 axis mill. It's a pain in the rear, but it works pretty good. I am talking with Shilen about getting them turned close to my finished contour, then I will take them from there.

Once I have the barrels turned down, I fit the shoe lump. I am able to machine it to almost fit off the mill, but it always takes a little work with a file. The shoe lump is then heat treated and tempered. While the shoe is in the oven, I machine the rib. I use a solid rib that I machine a trough on each side that the barrels mate to. It helps with alighnment and with a proper fit, it makes the barrel unit feel really solid even before soldering.

Here is a picture of the barrels, show lump and rib soldered together and partially cleaned

I assemble to parts with the barrels mounted on the spacer blocks at each end. I have the muzzels closer by a few thousandths each to provide an expected place to start for regulating. I set them on my mill table since it is as flat a surface as I have in the shop currently.

A picture of the breech end with recesses for the ejectors

A picture of the action, forend iron, and barrels

Finaly, a shot of the forend iron and action as they fit together. This is the fit directly off the wire EDM.

Next step is to begin machining the action to mate the major components. This is where it gets exciting!!

Bailey Bradshaw

| baileybradshaw |

| (.333 member) |

| 16/09/09 12:44 PM |

|

|

Worked on the front sight base this morning. With the EDM, I can cut the base to shape and the proper width. Since it is adjustable for spread, it is in two pieces. I have the barrels set to cross by a few thousandths, so the sight base is closed when installed. Here it is fresh of the EDM.

The base has two set screws, one in the front for adjustment, and a lock screw on top to secure the setting. After I drill and tap the holes for the screws, I shape the base and tin the areas that will be in contact with the barrels.

Here it is soldered in place. I will cut the dovetail for the front and rear sights in one operation, so both bases need to be in place.

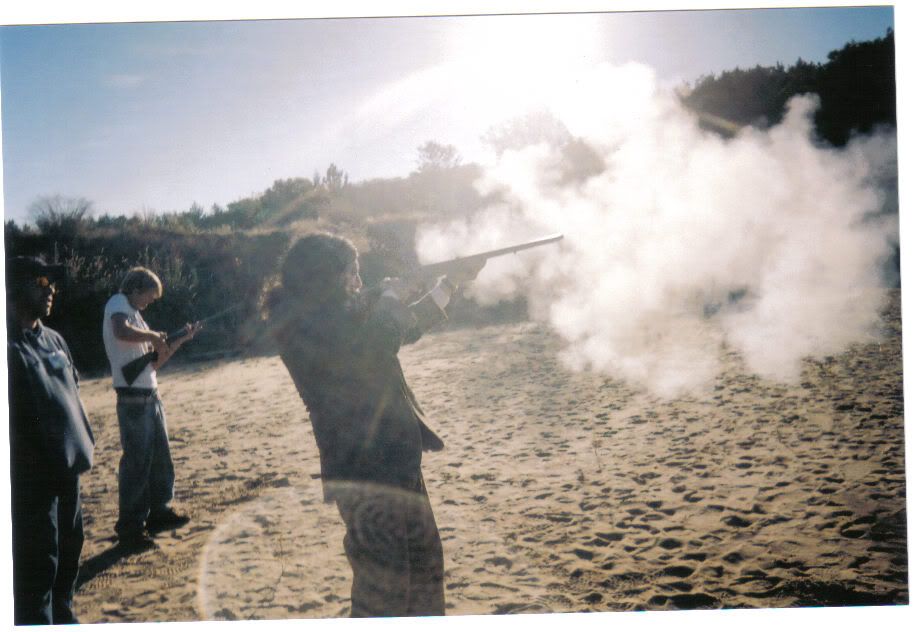

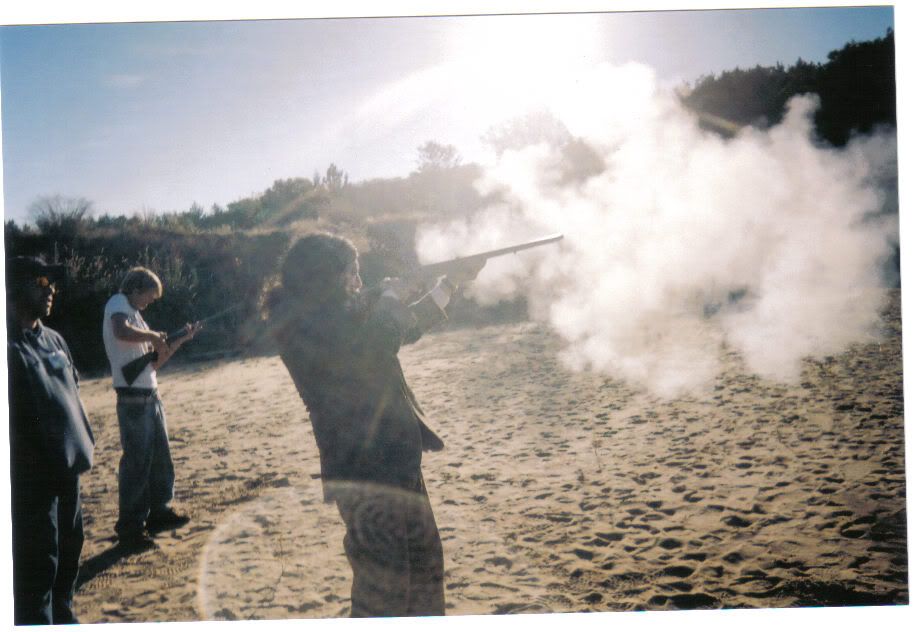

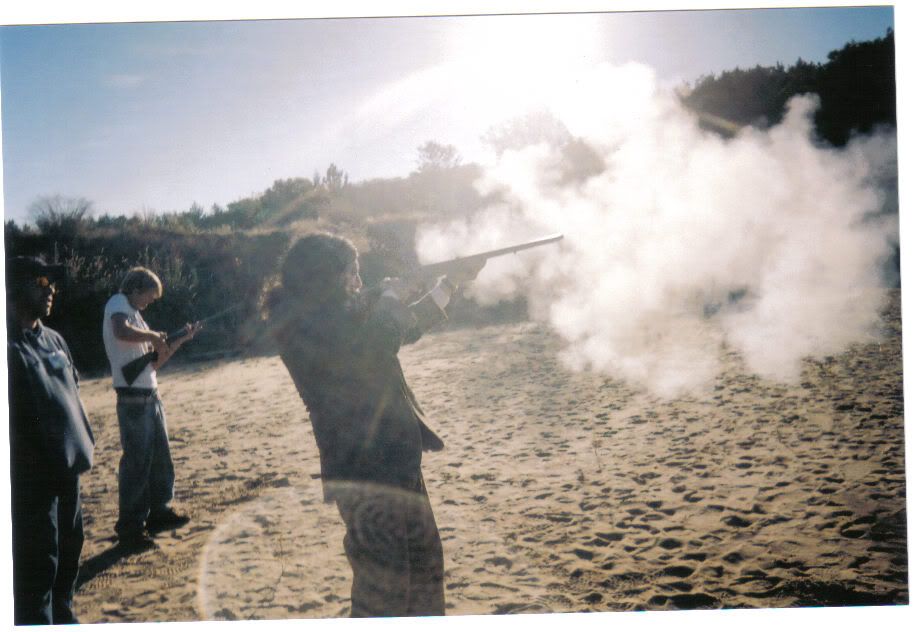

I've been shooting the heck out of my prototype rifle. It's more fun than the law should allow. Shot an 18" steel hog silouhette at 150yds yesterday. Can't say I had any kind of grouping, but was suprised I hit it consistently with open sights.....both barrels too! My son shot this video in front of the shop. The target is a block of tile grout that got wet and hardened, bottom right on the screen. It was getting dark, but watch it in full size and you can see the impacts.

| Mike_Bailey |

| (.400 member) |

| 16/09/09 04:57 PM |

|

|

She's looking good Bailey

I'm off tommorw to Africa, will email you when I get back, good luck, Mike

I'm off tommorw to Africa, will email you when I get back, good luck, Mike

| baileybradshaw |

| (.333 member) |

| 19/09/09 12:49 PM |

|

|

LOTS of machining to do at this stage, and there are a lot of details to check and double check. Make sure the vise is squared up with the X axis, double check positions ect.

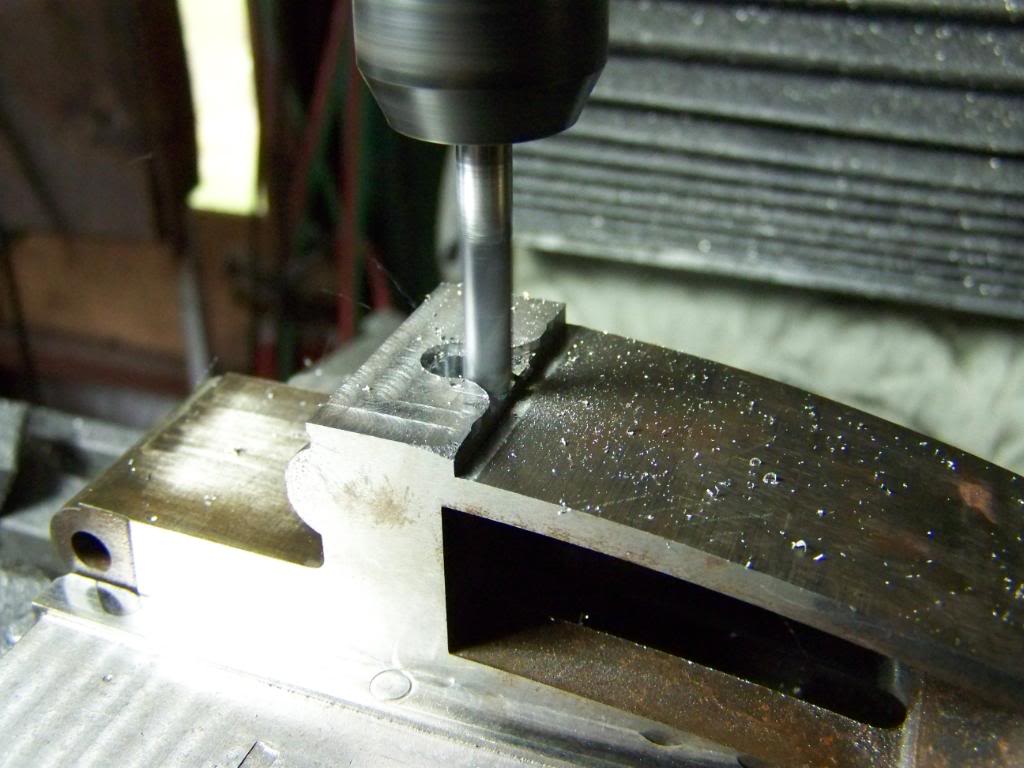

Here the trigger group pocket is beginning to be machined.

1 1/2 hr later....

Climb milling finish cuts leave a nice finish. There is more to do inside the pocket, but I have to turn the action over and machine the trunion cavity. That will allow access to machine the slots for the sliding bolt.

The top side machining includes the top lever pocket and rough machining the side clips and breech face.

The breech face is left "rough" because I will have to smoke in the face with the barrel faces, so machining too much off will require remaking the shoelump/barrel set. I leave .005" to clean up with the file and stones.

Once the trunion has been machined, I can begin joining the action and barrels. Useing a dummy wrist pin, here is the first mating of the action and barrels.

| baileybradshaw |

| (.333 member) |

| 23/09/09 10:39 AM |

|

|

Moving along nicely.

One lesson learned is to get everything that has an affect on the rifle being smoked on face fitted so I only have to do that one time. So the ejectors, striker bushings and of course the side clips are next. I locate and spot drill where the center of the bores will be. The firing pins are at a slight angle down and to the center of the action by about 5 degrees. Using a compound vise, I am able to drill the holes for the bushings, and counter bore the hole for the bushing. The bushing runs all the way through the action face, and the body is threaded. Here is a picture of the holes, and next with the bishings in place.

After the bushings are seated, I machine off the excess material down to the face. Remember I left the face with about .005 extra material.

I fitted the ejectors when I made the shoe lump, but since the barrels were not in place, fitting them requires machining the cavity where they ejectors will be. I would love to have a horizontal mill for this, but a modified keyway cutter is another way to get it machined. From here, I go in with rifling files and make sure it is flat and the ejectors fit.

The next step is smoking the barrels on face. I didn't have the camera at the shop yesterday when I did this, but I am sure most of you have seen it done. It's slow and tedious work, but I kind of like it. It ends up putting me in a zen-like state of mind and the time goes quickly.

Her is the action with the barrels on face.

With the barrels smoked in, I can begin work on the top lever and sliding bolt. Again, I use a keyway cutter to machine the slot for the bolt. The rifle has double underbites, so the bolt is too long to machine only from the bottom. This is one of those operations where everything must be good and square. Once I machine part of the slot from the bottom of the action, I flip it over and machine the forward portion. It the action isn't square and level in the vise, the slots won't line up and there will be a step where the cuts meet.

Here is a shot of the bottom of the action with hte barrels on. You can see the relationship of the underbites with the action. Nice snug fit in there :-)

| baileybradshaw |

| (.333 member) |

| 24/09/09 12:07 PM |

|

|

Worked on the lock slide today, and the top lever is on the mill now. I start with a 3/4"x.140"x3" piece of 52100. Machine the top lever dog hole and the underbite holes. Once those are machined, the part is surface ground to fit the slot in the action. At this point it is heat treated and tempered to 42rc. Here is the part after tempering.

A picture of it in the action

I file fit the lock slide to enguage the underbites. I don't want it too far into the underbites, just enough at this point to lock down the barrels. It has about 6 degrees of angle.

While waiting on the top lever to finish machining, I went to work fitting the trigger group housing. I will finish this up tomorrow, but here it is with the front end inserted. The trigger group will be removeable for cleaning, just one screw at the rear holds it in place.

| baileybradshaw |

| (.333 member) |

| 27/09/09 12:53 PM |

|

|

Here is the top lever after machining. I leave the final shaping to do by hand as there is so much character in the top lever shape, I didn't think I could get it just right on the mill, and it's not all that much to do with a file anyway.

the top lever with the cam for the lock slide.

The action has an additional pocket for the lever cam, it's being machined here. I always get nervous when machingin in confined spaces. Machines can do freaky thing from time to time.

once the pocket is cut and deburred, the top lever and associated parts can be installed and checked for fit.

Looks like I did OK :-)

The rifle's future owner wanted sling swivels installed. I didn't want the front eye to be too close to the forend, so I made a small rib to create some distance.

and here is the top side

Starting to look like it's little brother ( the stocked rifle is a .22lr, this one will be .22 hornet)

| mehulkamdar |

| (.416 member) |

| 27/09/09 12:57 PM |

|

|

|

If anyone had any doubts about why double rifles cost so much, the amount of brilliant work that these pictures show should silence them.

Quote:

Looks like I did OK :-)

This is the understatement of the century!

Thanks for the pictures, Bailey and please keep them coming. It is incredible to see this work of art in the making.

| hunt_ak |

| (.224 member) |

| 28/09/09 10:16 AM |

|

|

No doubt! This is amazing. I'm guessing you made your own wedding ring, too!

| baileybradshaw |

| (.333 member) |

| 01/10/09 01:42 PM |

|

|

I have the trigger group housing fitted in place and the retaining screw installed.

With that step complete, all of the internal machining has been done. Now I can start the exterior machinging. I use the 4th axis on the mill so I can rotate the action as needed. This is a tense process as a slip up is not repairable at this point. All of the external surfaces are machined leaving .005" over the finished dimension as designed. This allows me to finish the action without worrying about undercutting parts. .005" is actually a lot of material to remove with polishing stones and paper.

Here is the setup....

I figured a short video clip would be better than a picture at this point.

| baileybradshaw |

| (.333 member) |

| 07/10/09 02:15 PM |

|

|

Made a lot of progress, but didn't get pictures of all of it.

Once the action was rough shaped on the mill, I refine the shape with good ole files, stones and sandpaper. Most of this work is at the fences and arouns the trigger guard.

The forend is fitted with the latch assembly, and the barrel set is fitted with the bite. Once it is locked in place, I am able to shape it with the action

It's starting to look like a rifle!!

The next step is to fit and install the lockwork, firing pins and cocking rods. I also need to finish the ejectors. While have the machines running the lock parts, I will continue polishing the action and barrels.

| peter |

| (removed) |

| 07/10/09 06:55 PM |

|

|

|

bailey

you are doing a wonderfull job, i have been waiting for your posts with exicitiment.

best

peter

| alexbeer |

| (.333 member) |

| 07/10/09 07:39 PM |

|

|

|

Quote:

bailey

you are doing a wonderfull job

Hear hear to that, love seeing where you are at.

Quote:

i have been waiting for your posts with exicitiment.

You and me both Peter

Best

Alex

alexbeer.com - Rifle Maker

| Rigby62 |

| (.224 member) |

| 08/10/09 09:45 AM |

|

|

This has been truly amazing to see, what incredible craftsmanship. Thank you for sharing this.

| baileybradshaw |

| (.333 member) |

| 08/10/09 03:22 PM |

|

|

Today went as follows...... sculpt and shape fences and shoe lump at the breech, then...polish polish polish polish polish polish... deep breath....polish polish polish polish polish...

Here is my engraving bench with microscope. I do a lot of fitting and finishing under 10x magnification.

| baileybradshaw |

| (.333 member) |

| 10/10/09 03:28 PM |

|

|

The last two days have been spent making wood shaving and dust. I changed a few features on my CAD program for my stocks since I made my prototype, so I had to prove the programing, and I certainly wasn't going to put an exhibition English blank on the machine and test my work. I have a few blanks on han dso I picked one that is nice, but wouldn't fill me with remorse if all went South. As it turns out, the stock had some nice figure hiding in there. Here it is, almost finished machining the action inletting.

Since the program was good, time for the real blank to go under the cutter.

And a shot during the final stage of inletting the top side of the action.

The inletting is not machined close enough to fit the action. I just get a good start on the cavity and it ensures alighnment.

| baileybradshaw |

| (.333 member) |

| 12/10/09 01:46 PM |

|

|

This stage always gets me excited. It's that first feel with the stock that reveals so much time and effort. I must say, this one will be hard to see go. It feels great, fits me at the moment ( it will be too short at it's final length of pull)and due to the heavier wood, balances better than my prototype. Nothing like good, dense English walnut. Hope you enjoy!!

Two of a kind...

| baileybradshaw |

| (.333 member) |

| 13/10/09 12:26 PM |

|

|

Shaped the forend wood and sanded the stock to 320. Also have the first couple coats of finish on. I use Permalin to finish my stocks. I like both the sealer and finish. I start by applying a few coats of sealer until it stops soaking in, then follow with a thick coat of finish. Let it dry for a ferw hours, then wet-sand the surface buildup off. Recoat and repeat until the pores are all filled. This stock will only take two rounds as the pores are so small to begin with. From there, I can use a couple of methods depending on the level of sheen desired.

Anyway, here are a few pics....

| michaelj |

| (.224 member) |

| 15/10/09 01:41 PM |

|

|

Bailey,

First off thank you for this thread and just incredible work. With that said and with all of your obvious talent, whats up with that gun rack:)

Just kidding of course

Michael J

| baileybradshaw |

| (.333 member) |

| 16/10/09 01:13 AM |

|

|

Michael,

Well......one thing I am NOT is a carpenter. The rest of my shop is not much better...kind of a "finish as you go" approach :-)

| michaelj |

| (.224 member) |

| 16/10/09 11:40 AM |

|

|

Bailey,

That must be the only thing you are not good at from the impressive list of the things we know you can do. It is good to know you are mortal after all.

Again thanks for the thread your work is fantastic.

Michael J

| 450_366 |

| (.400 member) |

| 16/10/09 07:18 PM |

|

|

|

|

I could easaly build one of those gunracks, but i would be utterly amazed if i could come even close to building a gun like that, very nice indeed.

btw. Good to see that you use quality cartridges.

| Ironscot |

| (.224 member) |

| 21/10/09 02:31 PM |

|

|

I'm dying to see this thing etched and finished! Any thing new Bailey???

| michaelj |

| (.224 member) |

| 31/10/09 08:57 AM |

|

|

Bailey,

Anything new? Look forward to your progress report.

Michael J

CptCurl

|

| (.450 member) |

| 01/11/09 01:33 AM |

|

|

|

Me too! Waiting to see more.

Great information.

Curl

| baileybradshaw |

| (.333 member) |

| 01/11/09 01:16 PM |

|

|

OK, Here is an update....Please forgive the drop in quality of the pics. I am using an older camera until my good one shows up.

This is a shot of the bottom of the shoe lump/barrels. I've been fitting the ejectors and retainers. The ejector system I am using is similar to what would typicaly be on an O/U. Your basic coil spring ejector set up.

I've also been making and fitting the lock parts. I try to make mechanisms as simple as possible, which means as few parts as I can whittle down to. One way I accomplish this is to make the sear springs integral to the sear itself. The sear/spring also bears against the triggers making them return to rest after being pulled. The hammers will be driven by coil springs and are rebounding.

And at this point, the stock gets a coat of oil every day, mixed with a little rottenstone. I never do keep count of the coats, just keep going until it looks right. I would guess I have a dozen or so coats now...

| Birdhunter50 |

| (.375 member) |

| 02/11/09 01:03 AM |

|

|

Your talents are truely amazing. How did you ever find the time to learn and master all these skills? Bob

| tkv000 |

| (.300 member) |

| 07/11/09 06:31 AM |

|

|

|

Forgive my terminology, or lack there of...

Will it have a full rib between the barrels? or will there be a gap? If so, would it be possible to have a full rib? Or would that wreak the balance?

| baileybradshaw |

| (.333 member) |

| 08/11/09 12:02 PM |

|

|

No, there won't be a full rib. It is partly due to balance, but that could be compensated for. It is primarily so the barrels can be regulated by my customers. Rimfire ammo varies so much and everyone seems to have their favorite. The barrel spread can be adjusted by a screw in the front sight base.

I've seen several Dickson double rifles without a full rib as well.

| baileybradshaw |

| (.333 member) |

| 15/11/09 10:18 AM |

|

|

Sneaking in more work here and there. My Sporting Classics knives are keeping me plenty busy.

I have the ejectors working smoothly, and have been working on the trigger group. First pic is of the raw bar I will make the main spring stops from, along with the trigger group.

Here, with the stops drilled and installed with the hammers at rest, and next with the hammers cocked. I actually need to remake one ofthe hammers as the left hammer sits a few degrees forward of the right hammer. The right hammer is is perfect, and the only way to make them match is to remove more material from the sear notch to let it move forward to the left hammers position. That would be a bone headed thing to do, so I will make a new hammer...

Here we have the stops rough ground so the trigger group will fit into the action.

Next step is to install the cocking feet and cocking rods so the action will....cock of course. After that, it will be time to chamber it and get her regulated.

| baileybradshaw |

| (.333 member) |

| 02/12/09 12:32 PM |

|

|

OK, I've been working like a fool on knives for Sporting Classics magazine. When time permits, I sneak in an hour or two on this one. I have the action cocking and ejectors working.

I had to make a new set of hammers, and during programing, I mirrored the drawing not realizing I would need to make new spring struts to fit the new hammers. They needed a little tweaking anyway, so a new set was machined with improvements.

Since the action is damascus, so the stock furniture will be as well. Here is the grip cap...

and a quick etch on the action reveals a little of the damascus pattern....

I have the skeleton butt plate ready to install and will get a couple of shots when I am able to do that. The action needs a little tuning, firing pins and then it is time to chamber it.

| hunt_ak |

| (.224 member) |

| 01/01/10 05:30 AM |

|

|

Updates!!

| baileybradshaw |

| (.333 member) |

| 01/01/10 02:55 PM |

|

|

I am working on a BIG update. Left my camera at the shop, but will start the new year off right :-)

Thanks for the interest!!

| akjeff |

| (.300 member) |

| 02/01/10 11:16 AM |

|

|

Your work is simply incredible....thank you for taking the time and effort to share your knowledge!

Jeff

| Paul |

| (.400 member) |

| 03/01/10 12:33 AM |

|

|

This has to be one of the best threads ever, Bailey. For some reason it had never occurred to me sideclips would be milled that way.

Cheers

- Paul

| baileybradshaw |

| (.333 member) |

| 03/01/10 12:32 PM |

|

|

Big day today. Got her shooting without a hitch, and it was so close to being regulated, I went ahead and made two small adjestments, and she is shooting "barrel spread" at 25 yds. I didn't have the sights installed, so I left it there as a good place to start sighting in a final regulation.

So, now for pictures. First is the damascus skeleton butt plate.....and my feet :-)

Next is the action just before heat treating. The action is forged from 1075 and L-6 tool steel. These will get VERY hard, and that isn't what I am after, so I austenitize at 1400. This is just hot enough to harden, but not full hardness. In order to eliminate scale, the action is coated in anti-scaling compound from Brownells. It works nice, but sure is ugly...

and after the quench

The compound is removed by boiling in water. The action is then polished, areas not to be acid etched are coated with laquer, and the action is imersed in ferric chloride to etch the damascus.

the results are hard to photograph, but easily visable in person. Sorry for the fuzzy picture..

| baileybradshaw |

| (.333 member) |

| 03/01/10 12:45 PM |

|

|

Moving into the finishing step, so first up is the top lever. It will have a folding peep sight, so the center is left blank. not too much engraving, just a little touch of scrolls.

Pencil layout

and after cutting

The rifle will have QD scope mounts, so here are the bases installed in the rib, with the lower half of the rings slid in place.

These rings are my own design BTW.

While cutting the dovetails for the bases and sights, I went ahead and machined in my name/location and caliber on the barrel rib.

Last pic for this update is display of balance :-)

| Ron_Vella |

| (.333 member) |

| 03/01/10 01:02 PM |

|

|

Bailey, For me, this has been like sitting in a corner and watching Da Vinci painting the Mona Lisa!!!

| VonGruff |

| (.400 member) |

| 04/01/10 04:33 AM |

|

|

This is/has been the most captivating thread to follow. No where else could most of us watch a funtioning piece of art evolve from the raw lumps of steel and wood to where it currently sits. I can only imagine the anticipation with which the comissioner of this georgous little rifle waits for completion. I have had a couplle of customs built but like the majority can not look over the shoulder of the artisans who do the work for us. This is a rare priviledge.

Von Gruff.

| peter |

| (removed) |

| 04/01/10 05:25 AM |

|

|

|

bailey

still looking good, i cant wait to see the action etched and finally finished.

best

peter

| DarylS |

| (.700 member) |

| 04/01/10 07:32 AM |

|

|

|

baileybradshaw - you are a wonderful craftsman.

| tinker |

| (.416 member) |

| 04/01/10 08:06 AM |

|

|

|

I agree.

Quote:

baileybradshaw - you are a wonderful craftsman.

And it takes stones to go from concept to product as Bailey here has done - especially given the complexity and completeness of the project.

After all, this (recent line of rifles) IS Mr Bradshaw's first step into the gunbuilding world, isn't it..?

Cheers

Tinker

| baileybradshaw |

| (.333 member) |

| 04/01/10 12:30 PM |

|

|

Tinker,

You are correct, my little doubles are my entry into the gun biz. They have certainly created a steep learning curve, but that's the way I have always done things. Not that I think it wise or would recommend it to anyone else, just my nature I guess.

I appreciate all the complients and the opportunity to show the process on this forum.

I am working on a falling block design that resembles the H&H farquarson's, then on to larger caliber doubles. The falling blocks will be out this year, larger doubles will be in a couple of years.

| mehulkamdar |

| (.416 member) |

| 04/01/10 02:41 PM |

|

|

|

Gosh, with a first creation that is as exquisite as this one, there is no doubt that the future will be good. No, make it great!

Sir, you are a master craftsman and my hat's off to you!

| Buchsemann |

| (.333 member) |

| 04/01/10 03:38 PM |

|

|

|

|

Bailey,

You have definitely made a most impressive introduction of your abilities.

I look forward to watching your line of offerings grow.

Best regards,

Buchseman

| baileybradshaw |

| (.333 member) |

| 05/01/10 02:03 PM |

|

|

I was able to complete regulating today. Fairly painless, and I like the results. I used Remington factory ammo, 45gr hollow point. I used open sights, 50yds. Here is a picture of the final group. ( I pulled the far right shot a little, but not too bad considering it was freakin cold today)

After that, I went into the shop and polished the barrels up and touched up a couple of other areas on the action and forend so I can show it this weekend at the DSC show. The action will get another acid etch just to make it a litte deeper.

Hope you enjoy!!

| hunt_ak |

| (.224 member) |

| 05/02/10 03:35 PM |

|

|

Wow, you definitely need to get better pictures of that beauty!!

| FATBOY404 |

| (.400 member) |

| 05/02/10 04:17 PM |

|

|

That is a true beauty. You are a very talented craftsman.

Thanks for you postings.

| CHAPUISARMES |

| (.416 member) |

| 06/02/10 11:26 AM |

|

|

Hi BaileyBradshaw,

It has all been said previously by others on this forum, However,.... You are very artistic by nature and have the capabilities to put your thoughts and designs into practice. You have bought back the "Old World" use of damascus steel into the "Modern" era.

I sincerely hope that your firearms will become available in Australia as they are truly a wonder to behold.

Keep up the good work,

Cheers from Australia,

Jeff Gray

| Kalunga |

| (.333 member) |

| 08/02/10 11:38 PM |

|

|

Bloody nice! I love it!

Kalunga

| baileybradshaw |

| (.333 member) |

| 11/02/10 11:48 AM |

|

|

Alright,

I have the action blued, stock checkered and am going over all the parts one at a time to make sure they are right for final assembly. The damascus is etched deep enough that the high layers are polished, and the deeper etched layers are matt, so the pattern still contrasts even with the blueing.

Were almost there!!

| 4seventy |

| (Sponsor) |

| 11/02/10 12:33 PM |

|

|

Bailey,

You have done beautifull work on this little double, and the description and photos you have supplied throughout the build have been truely awesome!

Can't wait to see it totally finished. I'm also very much looking forward to seeing NitroX's double as it is built.

Thanks for this terrific thread!

| Shackleton |

| (.300 member) |

| 11/02/10 12:58 PM |

|

|

Beautiful work. I've been wanting a DR in .22 for years, but I want a .22LR or magnum. What I'd like to have is similar contours to a .410 shotgun, walnut stock and express sights-maybe 25, 50 and 75 yard leaves. Ideally a full rib and regulated for a common round like Federal bulk-I get nice groups out of my scoped bolt action, better than CCI match grade actually.Expensive project if it ever goes beyond the "I'd love to have one" stage.Also well beyond my skill level.

| baileybradshaw |

| (.333 member) |

| 15/02/10 02:49 PM |

|

|

Damn snow knocked out the power to my shop for three days....But I did have power at my home, so I brought her home to tune up the triggers. Take note of the springs. The coil springs I was using were just a touch too wide for the frame opening, and rubbed when removing the trigger group. I replaced them with Belleville washers. They are washers that are cupped. The cool thing about them is the amount of power they have in such a small space. These washers are significantly stronger than the coil springs. Plus, they allow fine tuning of the resistance by stacking them in parallel ( facing the same way). Not to mention, with 36 on each pushrod, there is a lot of redundancy so failure will never be an issue. They look cool too. Only drawback is they are expensive, $1 each.

Here is the trigger group partially inserted into the frame.

| Birdhunter50 |

| (.375 member) |

| 16/02/10 11:50 AM |

|

|

Very Pretty! I really envy your talents. Bob H.

| baileybradshaw |

| (.333 member) |

| 17/02/10 02:46 PM |

|

|

A folding peep sight....bad pictures, but the sight work nice.

| tinker |

| (.416 member) |

| 17/02/10 02:52 PM |

|

|

|

Bailey that's looking really sweet.

Good for you!

Back when I was a jeweler and designer 20-odd years ago, I loved the last hours of the projects the most - where everything came together as a unit and the projects took on their own character and life.

At times I'd feel the severance more than others when I handed the work off to the clients.

I can imagine you're feeling relatively proud of yourself on this particular rifle, and I'd guess there's just a little pinch of attachment to this one.

Cheers

Tinker

| Empire375 |

| (.300 member) |

| 17/02/10 03:19 PM |

|

|

Post deleted by NitroX

| JOAT |

| (.224 member) |

| 18/02/10 04:00 PM |

|

|

What a bummer. Logged on specifically to see how this was going. No pictures visible, period. When I originally ran across this thread, no problems viewing any of the pictures. Now zip. Any chance of checking that out and getting pictures I can view?

Thanks

Theo

| baileybradshaw |

| (.333 member) |

| 19/02/10 01:30 AM |

|

|

All the pictures show for me...

| JOAT |

| (.224 member) |

| 19/02/10 05:15 AM |

|

|

Quote:

All the pictures show for me...

I have no explanation at all, but all the pictures are visible to me today. All I can say is it must be my computer trying to drive me nuts. Sorry about that.

Lovely work, now I need to go back and read the whole thing over again. Very awe-inspiring.

Thanks

| 9dot3x74R |

| (.275 member) |

| 19/02/10 07:14 AM |

|

|

|

|

I had the same problem yesterday, many pictures in many threads weren't showing up.

NitroX

|

| (.700 member) |

| 19/02/10 06:19 PM |

|

|

|

The internet and some servers can have glitches from time to time.

| Cinghiale |

| (.333 member) |

| 20/02/10 04:46 PM |

|

|

WOW!!!!

This has been fantastic to watch and you deserve to be extremely proud of your achievements Bailey well done and I sincerely hope this is the start of a legacy.

Regards,

MOG

| baileybradshaw |

| (.333 member) |

| 22/04/10 03:05 AM |

|

|

Thanks for the kind words everyone. It has certainly been my pleasure to share my work.

I am a couple of days away from boxing her up and sending her off. Last thing to do is finnish the scope rings and do the final mouning of the scope. I designed and made the rings. Quick release by pressing the button on the side of the rear ring and slide backwards about 1/2".

From here, I will blue the rings, lap them for proper scope fit, and mount/sight in the scope.

Thanks again!!

| kamilaroi |

| (.400 member) |

| 22/04/10 09:17 AM |

|

|

Stunning!

| Shackleton |

| (.300 member) |

| 02/05/10 03:30 PM |

|

|

Beautiful rifle. I'd personally skip the scope(usually) but it's a nice option to have, and when the scope is removed the mount looks to be MUCH more discreet than a Weaver base. .22 hornet is a fun round, just got into it with a 10 inch TC Contender barrel, nice to see it in a classic design, properly proportioned for the cartridge. Thanks for the thread.

| baileybradshaw |

| (.333 member) |

| 06/06/10 01:32 AM |

|

|

It's finished. Been a ton of fun to build this little rifle. I sent it out yesterday to be reviewed by Chuck Hawks.

Before sending it, I double checked the regulation and sighting in of the scope. Final group at 50yds....

We have a range setup in a pasture behind my shop. One of the targets is a 18"tall steel pig siloet. The pasture fence to the pig is 220 yds. Standing, off hand, one shot from each barrel rang the steel. I like to use this as a hunting simulation as it looks and feels more real than a paper target. The hornet doesn't have a lot left at that range, but you can see the imapact marks.

Shots were about 8" apart. I wasn't shooting for a group, just mounted, and let em fly. I am pretty happy with it's accuracy.

Here's a few final pics.

CptCurl

|

| (.450 member) |

| 06/06/10 02:02 AM |

|

|

|

Congratulations! It looks nice. I would love to see it in hand and shoot it. Maybe some day. Do you have orders for other builds?

Curl

| baileybradshaw |

| (.333 member) |

| 06/06/10 02:45 AM |

|

|

Curl,

yes, I have 6 firm orders. Next one I am currently working on is a .22K-hornet with second set of .410 shotgun barrels. Another is a 3 barrel set with damascus action. Calibers will be .22 K-hornet, .410 shotgun, and .357 maximum. May add a 4th set in 6X70R.

The response has been great, and when more guns are delivered, I hope orders will roll in more frequently. One thing I am accutely aware of is the reluctance to place and order with a maker who has yet to prove delivery and service. That is just a matter of time, and I certainly understand it.

Nothing would thrill me more than to HAVE to hire help. Being a Navy veteran, I would like to hire a vet with gunsmithing experience. Marine armoror or Navy gunner's mate. All is due time....

| baileybradshaw |

| (.333 member) |

| 22/06/10 11:57 AM |

|

|

I just received this email from Rocky Hays. He is part of the gunsmithing staff for Chuck Hawks. The did a test firing of this rifle and will write an article on it to be up soon. I thougt it important to include the whole e-mail showing issues with the rifle as well as the good stuff. The issues are correctable and will be taken care of as soon as it's in hand.

"Bailey,

We got the Hornet out to the range for test firing, and we're all finished. It's boxed up, and I'll ship it via UPS Ground tomorrow (Tuesday); I'll send you the tracking number

We were not able to find factory Remington ammo; the only ammo we could get was Stars & Stripes, 33 grain speer tnt's. The gun shot very well with this ammo, although it

was about 2 1/2" high at 50 yds. The regulation on the gun seems to be perfect--I don't think you could tune it any better. Good job. We shot it at 150 yds and 200 yds; it

shot under 2" groups at both distances--still about 2 1/2" high and 2 1/2" right. If it were my gun, I'd probably zero the scope at 100 yds for the 33 grain ammo

We had some problems with the triggers. We measured the front trigger pull at 5 pounds and the rear trigger at 7 1/2 pounds; both trigger pulls seemed excessive. And the

trigger pull did affect the accuracy of our shooting--the left barrel (front trigger) shot tighter groups than did the right barrel. You told me how to remove the trigger pack, but

we did not remove it, and we made no adjustments on the triggers. When we dry fired the gun to test trigger pull, the right firing pin remained protruded and was catching the

extractor so that we couldn't open the gun. Also, the right firing pin seems a little high, as it is making drag marks on the casings

The staff really liked this little gun, and loved the idea that it was made with Damascus steel--it was very pretty and very unusual

It may be as much as a month before the article on your gun is posted; I will send it to you as soon as it's up

Rocky"

| 4seventy |

| (Sponsor) |

| 23/06/10 08:02 AM |

|

|

Quote:

When we dry fired the gun to test trigger pull, the right firing pin remained protruded and was catching the

extractor so that we couldn't open the gun.

They were dry firing your new double?

What were they thinking!

| baileybradshaw |

| (.333 member) |

| 23/06/10 08:39 AM |

|

|

It matters not. With rebounding hammers, it won't hurt it. The pesky firing pin is an easy fix.

I thought it funny they shot it at 150 and 200 yds. Glad it shot well at those ranges, but that little 33grain bullet doesn't have much left at 200yds. Nice to know if that once in a lifetime duiker pops out at 150, you can hurl some lead with confidence.

| DarylS |

| (.700 member) |

| 23/06/10 11:25 PM |

|

|

|

I'm surprised the rebounding hammers/pins doesn't cause pierced primers. Perhaps the pin is depressed long enough for the pressure to subside somewhat.

| 500grains |

| (.416 member) |

| 24/06/10 12:11 AM |

|

|

|

Those petite doubles are a joy to swing on target.

| Sniper |

| (.224 member) |

| 08/09/10 06:05 PM |

|

|

|

|

B E A Utiful is all i can say.

will the gun stay as it is ie without a complete rib. or will a rib get added latter on.

/S/

| kamilaroi |

| (.400 member) |

| 08/09/10 06:27 PM |

|

|

A very fine bit of work Mr Bradshaw!

| DarylS |

| (.700 member) |

| 09/09/10 06:35 AM |

|

|

|

Yes - it's lovely.