| Trailboss |

| (.275 member) |

| 24/04/18 06:27 AM |

|

|

93x64mm will send you what I have tried and what worked and what didn't and maybe why.

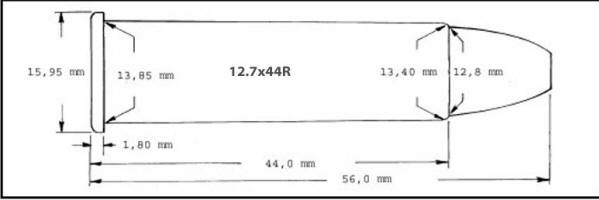

Daryl_S, The groove dia on the Husqvarna 12.7 is .515. The groove on the Remington is .513, that is where the rub is. The original boolit used by the military was a swagged boolit of 365 grains with a dia of .497, Lots of folks have had no problem using the larger boolit in their chambers, but in mine it was not to be, I may even at some point set up a jig to mount the cast boolits in and drill out a cavity in the base like the original design and issued boolit were to help the boolit seal the barrel if I have an issue with the solid base, but I will first go softer with the alloy to see if I can get it to upset that way first if I have that issue.

I am using the 50 Alaskan brass by Starline for the case, it fits like a bad habit, I cut them down to 44 MM and then fire formed them twice using Unique, then with the two Lee mold I had ordered in the 515 diameter I carefully opened up the case mouths just enough to get the unsized as cast Lee boolit in........A big NO GO in the chamber, stopped quarter inch from entering all the way. SOOOOOOO, I ordered a Lee .510 sizer to squeeze these 515's down a little to see if that would work, Noooooooo, not this time either, so I like a dummy order the Lee .501 sizer and then promptly got the boolit stuck in the die, ha, ha, ha. Ok, flipped the die upside down, got out the drill and drilled most of the center of the lead 450 grain boolit out, the turned it back right side up and got an old c-clamp that I had removed the flat disc on the end of the screw shaft, taped it with cloth electrical friction tape and proceeded to slowly turn the screw down on the boolit and it just popped out. Ok, plan D, wait for the postal lady to bring me the Lyman Plains mold I ordered earlier in the week just in case this very issue came up. It is made for a muzzle loader, 395 grain, tail end is smaller than the front, something like .506 on the tail and .509 on the front. It arrived on Saturday's post, got right to it, cast them up, cut down another 17 cases, this time I sized all the cases through the Lyman 50-70 Govt dies instead of fire forming, the unsized boolit just entered the case mouth up to the second band from the base, perfect. Ok, got out the pyrodex, RS, pulled out the BP 36" drop tube I just made last week and proceeded to fill up all seventeen cased with a starting load of 50 grains of RS. I weighted the drop on my electronic scale and it came to 42.8 grains, so I loaded all of them up, compressed the powder just till it was taking up the strain, and them covered the powder with a card I punch out with my new arch puncher I got on Thursday of last week. Lubed the boolits with Wonder lube 1000 from TC and then pressed them in until they met firm resistance of the powder and card. Now came the test..........would they chamber? YES, slid in like flint!!!!!!!!

The next test will be to see how they shoot at 50 yards, and how the lube works or doesn't.

Will post as to the outcome of the shoot and any issue that arise thereof. Meanwile, here are a few images of the weekend labors of love.