| AFRO408 |

| (.333 member) |

| 25/07/11 08:30 PM |

|

|

|

|

Cap'n Curl & Daryl,

The die came from Huntingtons here is a link to the page.

http://www.huntingtons.com/bulletmoulds.html

Alloy is 10lb of wheel weights + 2oz of tin approximately. I seem to get better finish on the bullets with a little extra tin.

I don't have a hardness tester, but I can still mark the bullets easily with my fingernail and when retrieved from the dirt, they are distorted but mostly intact.

After firing them I had a look at the muzzle and the rifling was just uniformly grey with powder residue and I found one tiny little speck of lead on the patch when I cleaned the bore.

Groove diameter of the barrel is .410" and the patched diameter of the bullet is about .414".

Un-patched diameter of the bullet is .406" and I thought that they were going to be too big, but obviously not.

I just took some pictures of the recovered bullets and they show nice deep rifling marks, so they must obturate.

The smaller ones are from my .310 Cadet.

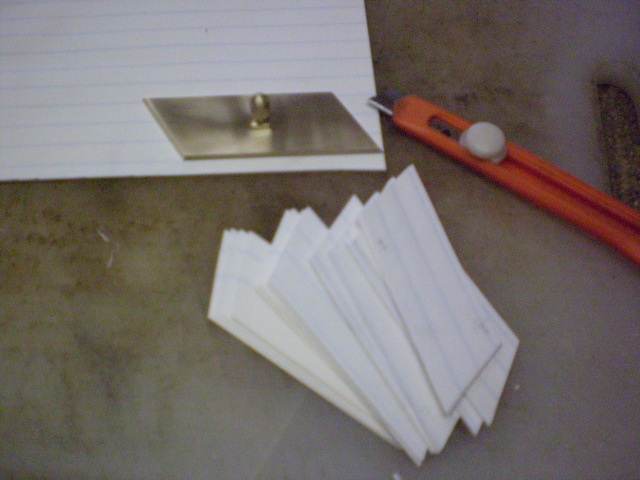

I also made myself a nice brass pattern for cutting the patches. I was cutting a dozen at a time here.

Ben, the rifle is not completed yet, but I hope to get started on the stock later in the year. I wanted to make sure that the takedown system didn't need any modifications as well.