| Perry |

| (.275 member) |

| 05/06/11 07:10 PM |

|

|

I went to the Range on Friday to try a couple of loads I put together for my 35.303

I used a Lyman 358315 mould that a very generous Gentleman Loaned me and straight Wheel weight Lead which I quenched in a bucket of cool water then allowed to sit for a month or so. They should have been somewhere around 18 BHN. They weigh 208 grains and are a Gas check projectile that I sized using a Lee .358 sizing die. The Gas check was fitted when I sized the projectiles and then I pan lubed them

I am a DIY type and I had the followed ingredients on hand so mixed 2 different Bullet Lubes, the first was a Bee's Wax, Parrafin, Carnuba Wax and Auto Transmission Fluid mix. The 2nd Lube was Lee Alox, Parrafin and STP Oil treatment. Both where quite stiff mixes and not tacky

I was unsure of the suitability of either bullet lube for my needs so I thought it best too try both with the same powder charge to see if one was any better than the other or if both where no good.

I used 3 times fired cases that I have only neck sized. The projectile was lightly crimped in place but the Neck Tension was such that this was probably unnecessary. I got the impression that by chance the tapered expander in my Die set is just the right diameter to open the case neck so the Cast projectiles seat firmly but not a tight enough to size the projectile down a little more

Up until this point I had used 44 grains of AR2208 under a 225 gr Sierra Gameking, it's a mild and accurate load. I have no interest in pushing this SMLE any harder but I'm sure it will handle a stiffer load.

The load used was 38 grains of AR2208 [ Varget ], 208 grain gc Cast bullet. I knew it would be a light load but I was being cautious as I figured it will still be doing 1900 + fps and I was leary of Leading the barrel if the Lube was no good. AR2208 [ Varget ] fills the case well, around 70% so I was not worried about it falling away from the primer.

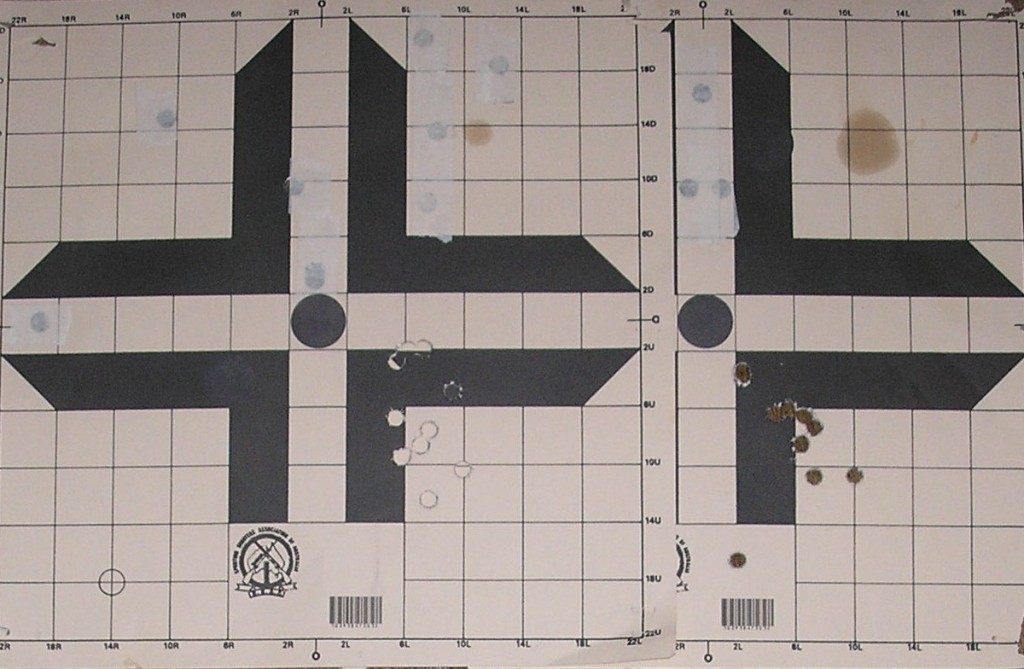

Here's 2 10 shot groups, Left the Alox lube , Right the ATF lube, not much in them but I like the shape of the Alox group better. They where fired at 50 metres off a Bipod and unsupported Stock, so no great shakes, still MOA Pig or Goat though

As expected the 38 gr load was light, the case necks did not expand and seal well as the case's had a bit of soot around the Neck. I am happy with the potential this Rifle is showing with this off the Shelf Cast Bullet Mould. Ideally I would like to shoot 250 gr Cast Bullet at around 2000 fps. I have cast several hundred of 358315's to keep me going in the mean while. They feed OK from the magazine but I'd be happier with a longer projectile.

Cast Bullet Engineering http://www.castbulletengineering.com/page0041.html list a Mould that looks just about ideal for my needs - just gotta save a little more. In the mean while the 358315 mould seems well worthwhile and I can see I'll buy my own soon enough. I am also thinking about getting myself a .359 Sizing die in a direct comparision with the .358 sized projectiles

Next range session will have loads starting from 39 gr of AR2208 [ Varget ] going up in 1 grain increments with the Alox STP, Parrifin lube. I'll fine tune after the next session.

regards Jacko