| buckstix |

| (.400 member) |

| 17/12/15 03:29 PM |

|

|

|

Hello lancaster,

Well, I had a big problem come up with my rifle.

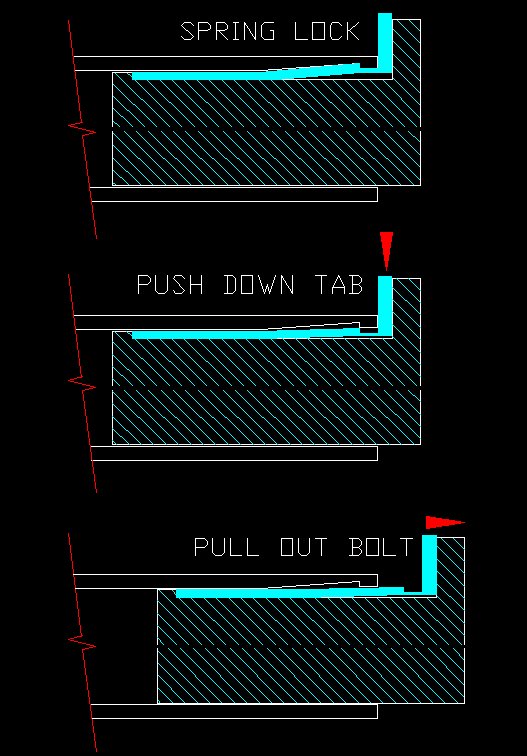

As you know, the bolt lock is a flat spring arrangement on top of the bolt. When the bolt is pushed in, it snaps into a recess inside the rear of the receiver, and locks the bolt in place. To move the bolt to the rear, you push the tab at the end of the spring which unlocks the bolt. Here is a diagram of the function.

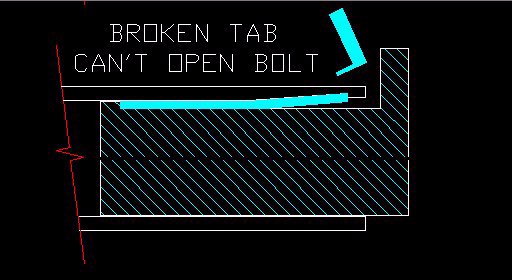

However, on my rifle, the tab at the end of the spring "broke off".

When I went back and examined the pictures I had taken when I first got the rifle, I could see that the tab was already cracked. You can see the crack in this close up picture.

I examined the broken spring and tried several times to repair it by soldering the broken tab back on to the end. Each time I tested it, it failed. I tried to fix this for over 2 hours, with nothing working. And then on my last attempt, the repaired tab came off when I closed the bolt. Now I was in a fix. I could not remove the bolt. The bolt was LOCKED in the forward position.

I tried to wiggle a sewing needle into the back to catch the spring, but that didn't work. I tried to make a small flat hook from a piece music wire, but that didn't work. Every thing I tried could not open the bolt. It was now the 3rd hour of trying to remove the bolt. I went to bed.

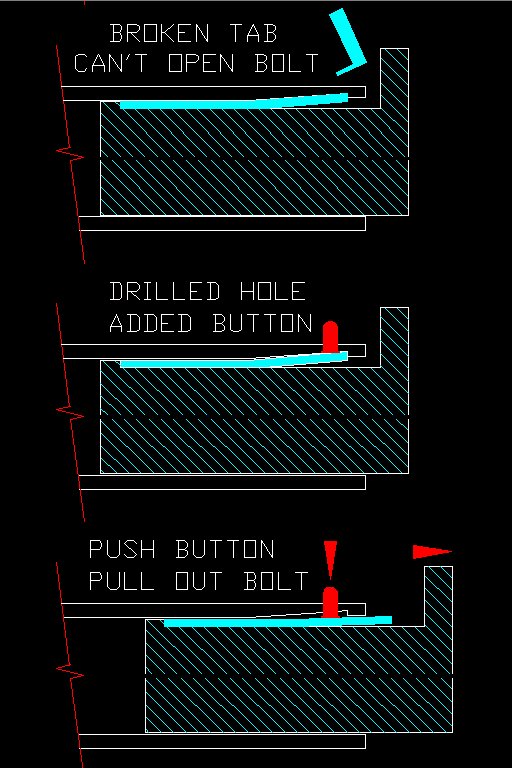

I called several gunsmith friends and asked for their opinion on how to remove the trapped bolt. They all came to the same conclusion, "I was screwed", and the only way to get the spring depressed was to drill a small hole in the top of the receiver, and push down the spring. As much as I hated to do it, I agreed that was the only method, or else it would be a wall hanger forever. I wanted to shoot the rifle, so I drilled the hole, and it worked. As soon as the the hole was drilled through, I pushed on the drill, which depressed the spring, and the bolt popped free.

So, I solved one problem, but now I had 2 more problems. I still had a broken spring that couldn't be repaired or replaced. And, I had a hole in the top of the receiver. So, here is what I came up with to solve both problems.

I added a button.

I really don't like altering vintage rifles, but in this case I had no choice because I wanted it to function. I wonder how many others like this are permanently LOCKED closed from a broken off tab. In the end, if you didn't know how the bolt lock was suppose to function, you would think the button method was original.

Now, the good news is I've had a chance to shoot the rifle and chronograph the loads. I fired it 10 times with the loading method I described previous, and only had one miss-fire. The miss-fire happened early, on the second loading, and I determined that it was caused by powder getting between the cap and the base of the bullet. When I made sure that the cap was alway tight against the base of the bullet, I had no more miss-fires.

100g bullet of .355 dia with 9.5g of 4Fg GOEX powder - averaged 575 fps.

100g bullet paper patched to .375 dia with 9.5g of 4Fg GOEX powder - averaged 690 fps.

That's about the same ballistics as a 38 short colt. Based on this performance, I'm thinking these rifles were more useful as Rook & Rabbit rifles, or as Gardener's guns, than as a parlor plinker.

Our target holders are made of 3/8" thick plywood, which were was easily penetrated with the 9mm bullets. So, that means that you would have to have a bullet trap in your parlor.