| buckstix |

| (.400 member) |

| 14/12/15 01:19 PM |

|

|

|

Hello lancaster,

I slugged the barrel and it measured .353" bore and .375" groove dimensions. The rotating chamber measures .390" diameter and is .740" deep at the straight sides to the corner of the curved bottom, and .770" deep at the center of the curved bottom at the needle hole.

I made a brass tool to remove the rotating chamber nut. I expect to do this often for cleaning.

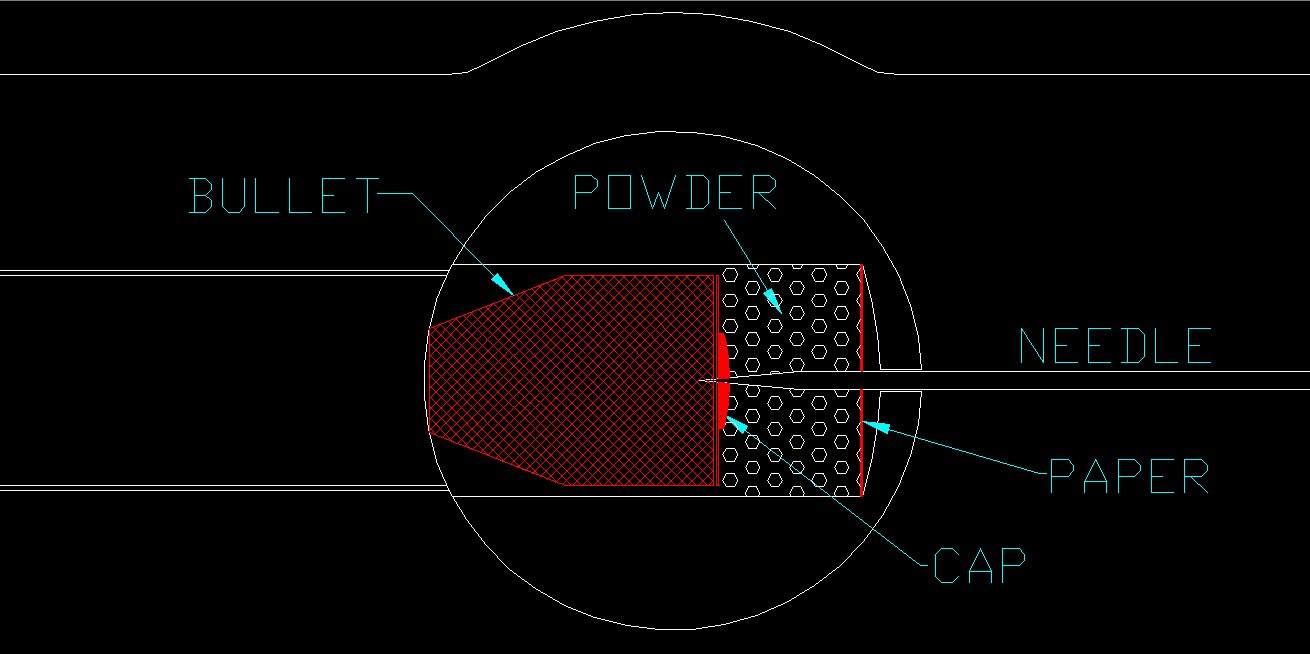

Shown are:

the bullet which is 100 grains and .355" diameter,

the paper cap which is cut from a roll of caps,

and a paper disk to cover the needle hole so the powder doesn't run out.

The truncated bullet is a 9mm luger pistol bullet and is copper washed with a single grease groove.

In my next test I will try paperpatching the bullet to bring it up to a larger diameter.

The diagram is to scale and shows the loading. First I put in the paper disk, then the powder, then the cap, then the bullet, then top it off with grease. I don't think the grease is needed but it helps keeps the bullet in place as I rotate the chamber in-line with the bore.