| GABE93 |

| (.275 member) |

| 17/04/17 10:37 PM |

|

|

Adding more to my post, sorry for the slow progress.

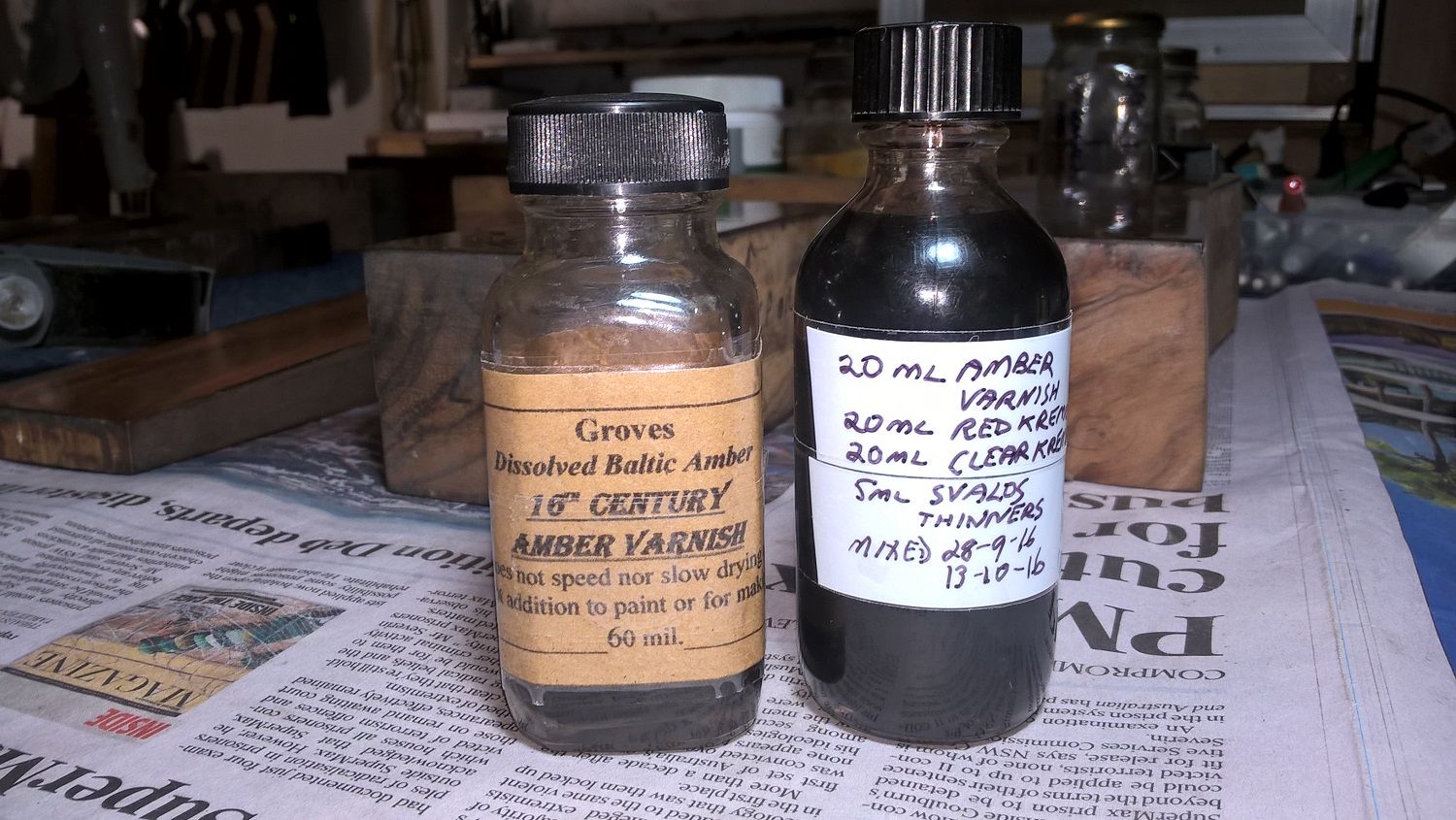

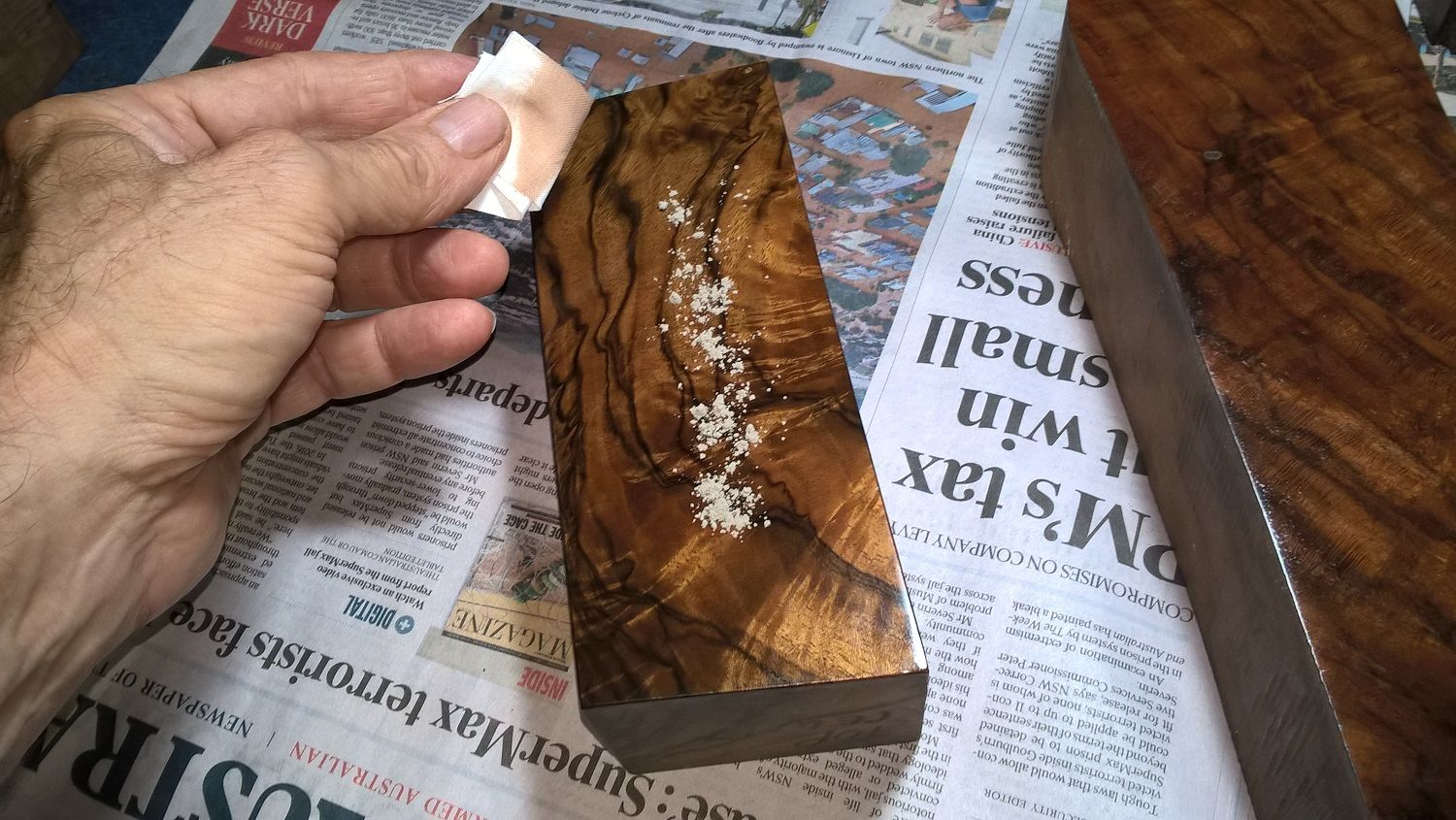

Some basic testing of surfaces rubbed with an amber varnish & linseed mixture. The Groves amber varnish is made with 50% Baltic amber, 50% walnut oil & a bit of gum turps. He makes several types of resin varnish. I'm trying the amber varnish as Baltic amber is the hardest/best natural resin. A link here to his amber info. http://www.jamescgroves.com/germanambervarnish.htm

[image]

[/image]

[/image]My first mixture was 20ml amber varnish, 20ml red linseed, 20ml clear linseed & 5ml svalos thinners. I didn't add any driers,wax,filler,alcohol,venice turps etc as you see in various old style linseed formulas. Each time I applied the finish I then added 2 drops driers to 1/4 teaspoon finish.

This first mixture has a lot more oil and a lot less driers than Groves recommends for violin varnishing. It was drying enough to advance the work in 24-36 hours. One time I placed one offcut in the sun for 2 hours and it dried a few hours faster.

In the images below some offcuts had 3-4 coats mixture rubbed very thin over a filled surface, with a nice lustre and no visible built up coating. A couple of offcuts I am still filling had no extra coats rubbed on top. None had any wax applied. [image]http://[/image] [image]

[/image] [image]

[/image] [image] [/image] [image]

[/image] [image] [/image] [image]

[/image] [image] [/image]

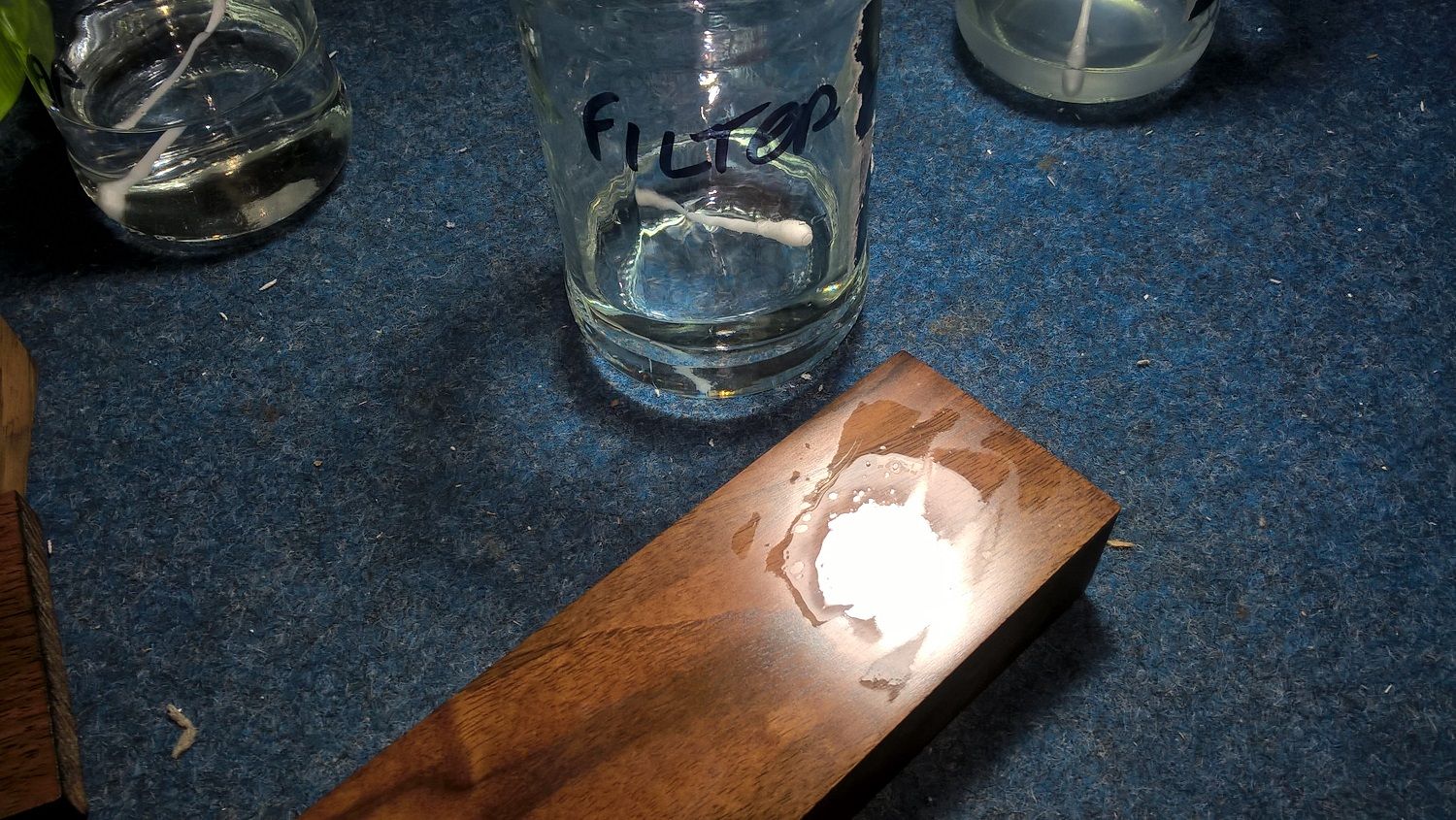

[/image]The images below, wiping the surfaces with thinners, sweat & water didn't cause any marks. Standing puddles of thinners didn't cause any marks. Standing puddles of water & sweat made spots on a couple offcuts, a hint of spots on a couple and on one offcut made no marks at all. [image]

[/image] [image]

[/image] [image] [/image] [image]

[/image] [image] [/image] [image]

[/image] [image] [/image] [image]

[/image] [image] [/image] [image]

[/image] [image] [/image] [image]

[/image] [image] [/image] [image]

[/image] [image] [/image] [image]

[/image] [image] [/image] [image]

[/image] [image] [/image] [image]

[/image] [image] [/image] [image]

[/image] [image] [/image] [image]

[/image] [image] [/image] [image]

[/image] [image] [/image] [image]

[/image] [image] [/image] [image]

[/image] [image] [/image] [image]

[/image] [image] [/image] [image]

[/image] [image] [/image] [image]

[/image] [image] [/image] [image]

[/image] [image] [/image] [image]

[/image] [image] [/image] [image]

[/image] [image] [/image]

[/image] I want to achieve more reliable resistance to water marking so I will increase the amber varnish ratio.

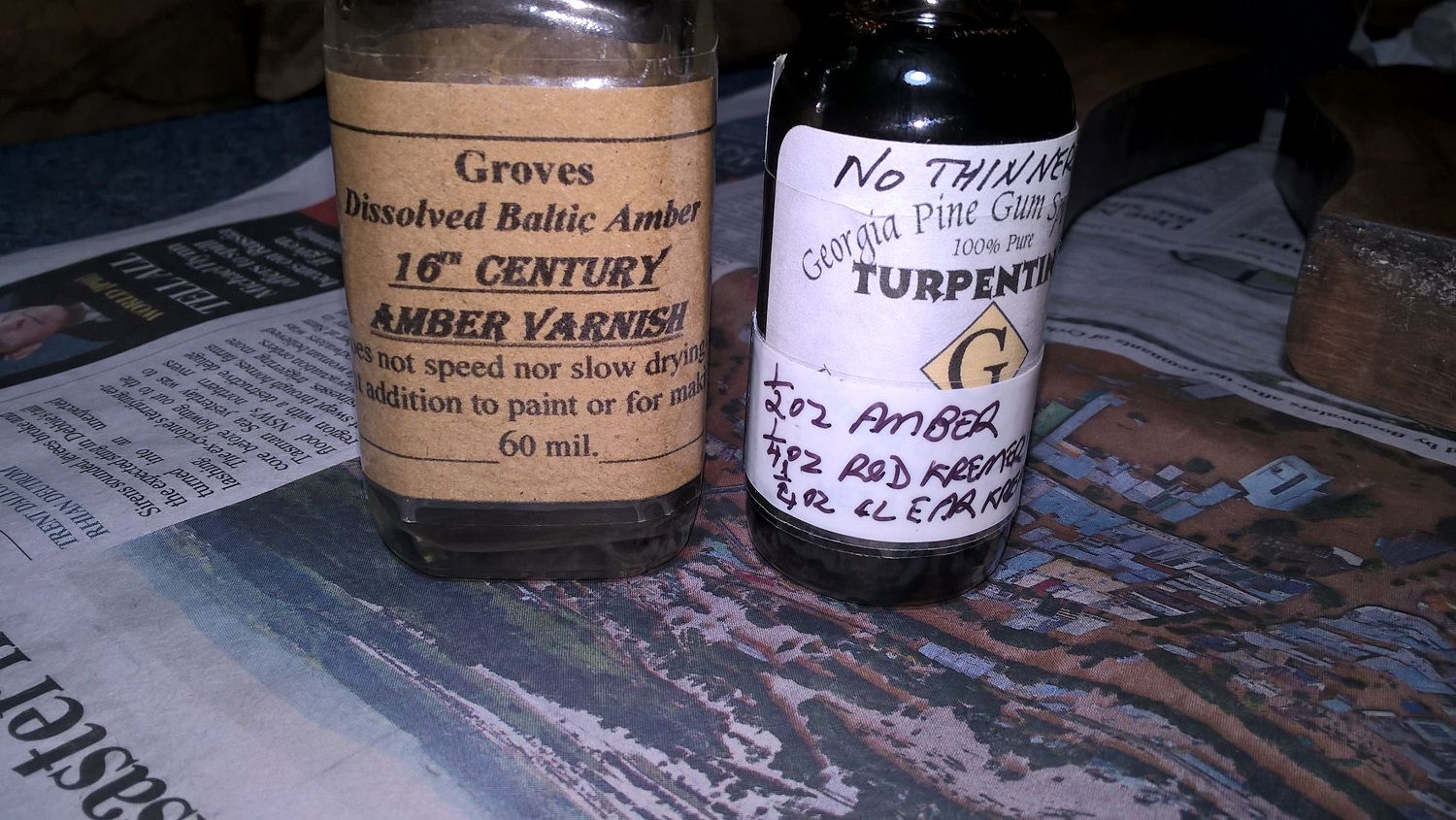

My next mixture is 1/2oz amber varnish, 1/4oz red linseed, 1/4oz clear linseed. No thinners added to this bottle yet as I noticed some residue settling in the bottom of the first bottle so i have to test if it was due to the svalos thinners.

[image]

[/image] [image]

[/image] [image] [/image]

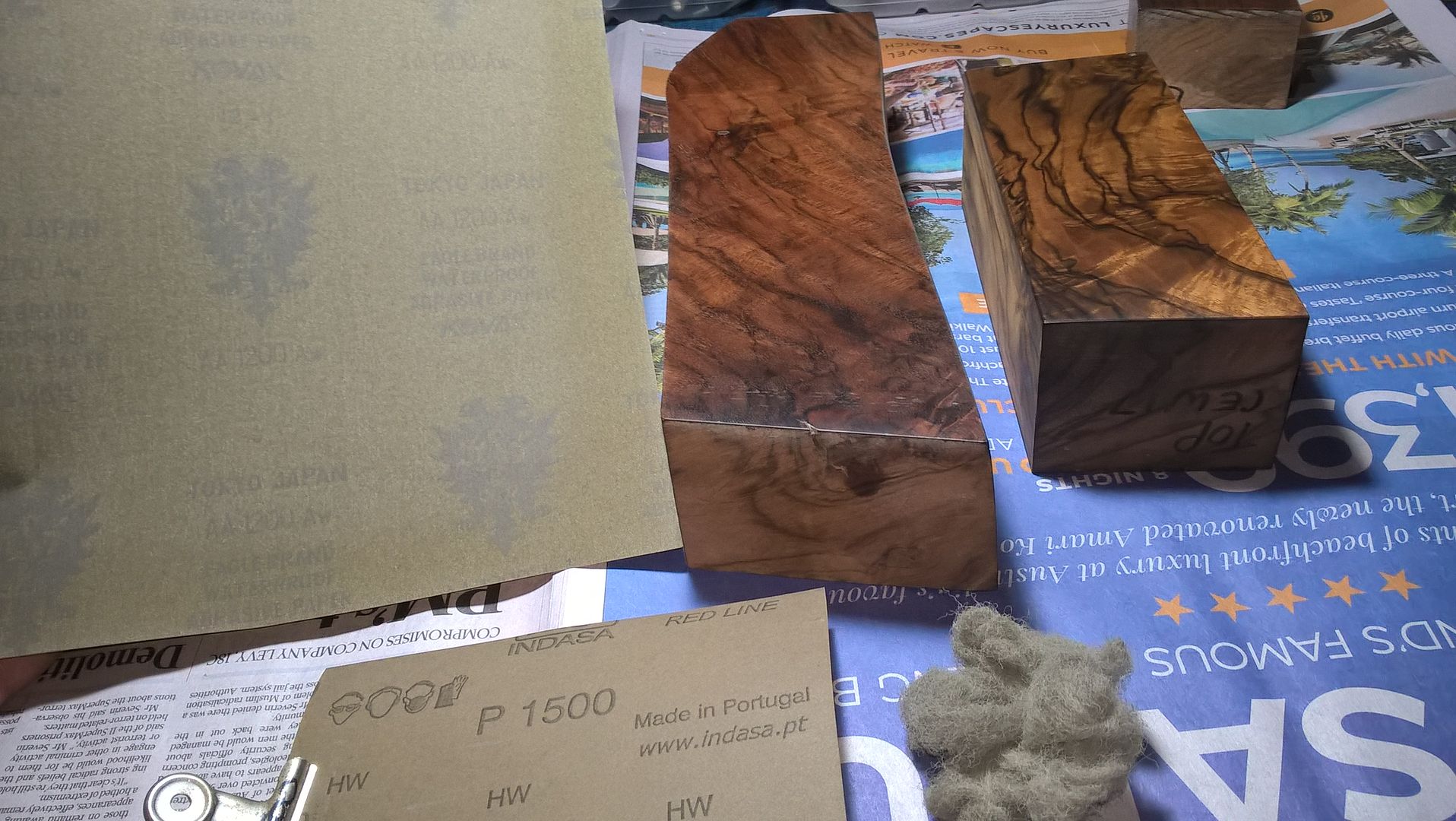

[/image] The images below, i cut down the various surfaces a bit, to continue testing with the new mixture, using 1500g w/d paper, 0000steel wool and Dico synthetic wools.

[image]

[/image] [image]

[/image] [image] [/image] [image]

[/image] [image] [/image] [image]

[/image] [image] [/image]

[/image] I will continue the post tomorrow afternoon. I have to sort through more images for the next stage.

Continuing with the new mixture, some offcuts that were already filled, now polished more with rottenstone and the finish on a cloth pad, then the slurry wiped off completely. Then the surface palmed off more, and checking closely the surface doesn't have any grey haze at all from the rottenstone. I will do this a few times and build up the lustre then retest with water when I think the finish is fully cured.

[image]

[/image] [image]

[/image] [image] [/image] [image]

[/image] [image] [/image] [image]

[/image] [image] [/image] [image]

[/image] [image] [/image] [image]

[/image] [image] [/image] [image]

[/image] [image] [/image]

[/image]