| GABE93 |

| (.275 member) |

| 05/04/17 07:12 PM |

|

|

Adding a bit more to my main post...

Some images of washed/bleached linseed here.

This image below some bleached linseed from Canada, the light colour when I received it. Made from Canadian cold pressed oil I believe.

[image]

[/image]

[/image] Then the same oil, changed colour after sitting on my shelf a few months.

[image]

[/image]

[/image]Then the Canadian oil with the Dictum cold bleached Swedish oil. The colour of the Dictum oil is unchanged since I received it.

[image]

[/image]

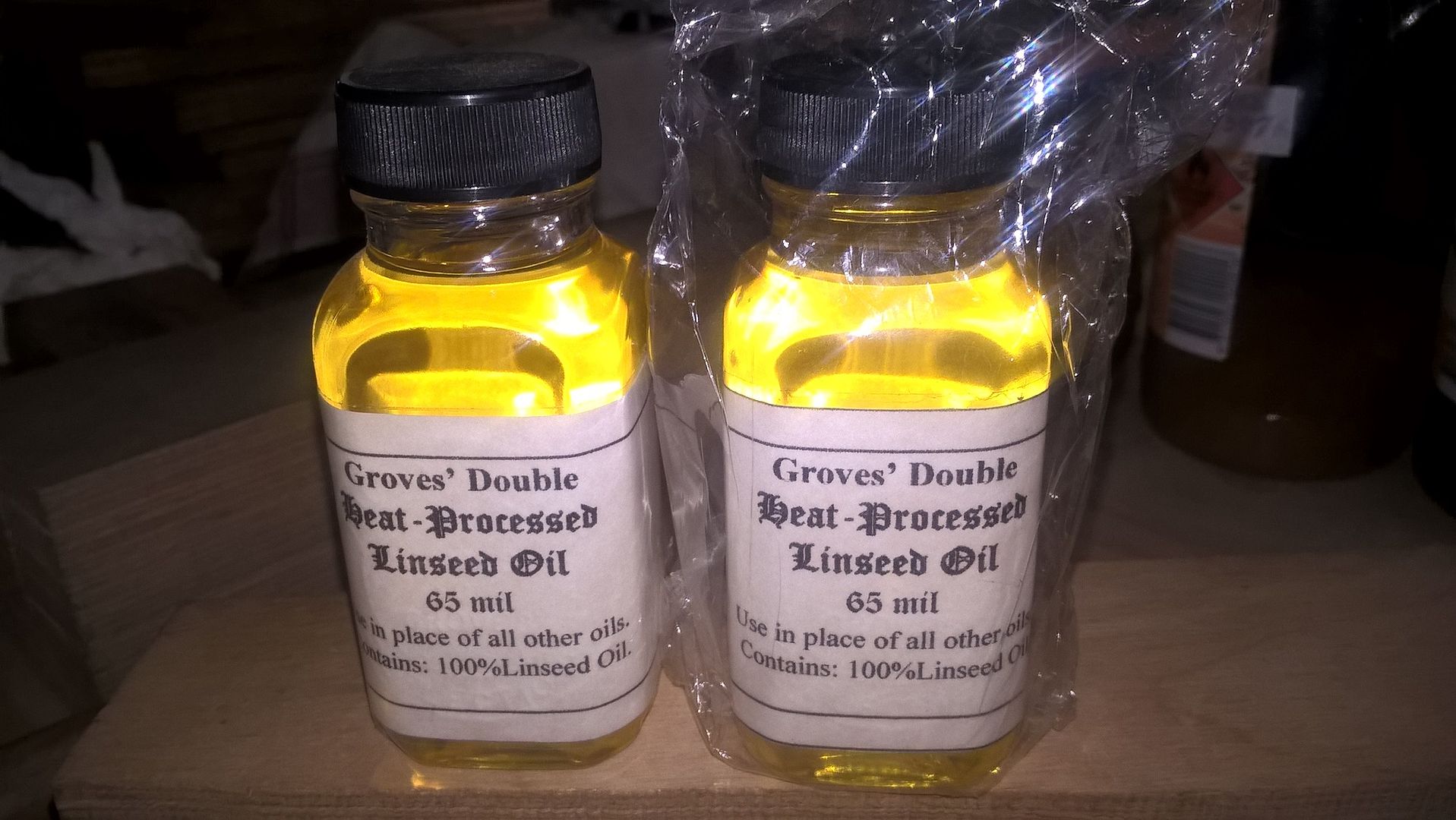

[/image] Then some heat processed linseed oil from James Groves, made from a good cold pressed flax oil without any washing, just his heat process. Link here to his linseed page. http://www.jamescgroves.com/linseedoils.htm

[image]

[/image]

[/image]All of these have remained transparent with no sediment settling out to the bottom.

The thick oil from Canada, with some Svalos thinner, felt a bit unusual to rub in. The oil from Canada cost a lot more and does not seem to offer anything extra to me so won't buy any more.

The drying time for all the oils I have posted has not varied a lot, all with 2 drops driers per 1/4 teaspoon. I didn't time the drying by the hour. I usually checked the offcuts morning and evening or day to day.

They all dried from 1-2 days. Sometimes the bleached oils took 3 days to dry. The humidity varies a lot here, from high to higher. That's why I have added driers to the initial coats of red oil on the Turkish walnut blank shown earlier, and many other finish's tried in the past.

Even with driers it still takes a long time to set, many hours, so I am still getting a lot of penetration into the walnut. Subsequent coats still penetrate into the wood.

The image below, some walnut off cuts used to test the drying rate of all the oils I purchased. A pale image. I'm not trying to show the finishing quality here, just explaining some testing procedure. I didn't try to achieve a perfect finish here. I used these to test only the oil's drying rate. These offcuts already had some old hard finish on them. After a light cutback I rubbed on thin coats of oil. The oil doesn't penetrate much this way and it is much easier to feel how the oil is drying.

[image]

[/image]

[/image]The drying rate is quite different when I mix Amber varnish into the linseed, for the pore filling and top coats. I'll take more images of the amber mix and applying it to some other offcuts here next.

Regards,

GABE