| GABE93 |

| (.275 member) |

| 01/04/17 07:59 PM |

|

|

To anyone interested in linseed oil for stock finishing, here is some info' I can share about better quality linseed oils, alkanet, resins and "English" style gunstock finishing.

I still have a lot to learn about the subject and I'm not trying to tell anyone linseed oil is the best stock finish. The content here is about optimising the linseed and achieving a better linseed finish.

We could easily start a separate thread discussing what might be the best gunstock finish using the many different products a lot of us have tried. I don't think there is one finish that is the best in every characteristic we want in a gunstock finish.

There is too much for me to post in one time so please be patient.

I tried hardware store BLO many years ago as an uninformed teenager. Over the years I also tried many other finish's as many woodworkers do. Much more recently I became interested in the "English" style linseed finish.

After my accident I spent many hours researching the subject and purchased various oils etc to try.

A shelf here with various linseed oils and walnut offcuts- [image]http://

[/image] [image]http://

[/image] [image]http:// [/image]

[/image]Various recommendations were to use cold pressed food grade linseed (flax seed oil). I don't trust food grade oils as they can have added vitamins and anti oxidants, even if the label says 100% pure oil. A lot of these oils can also be cloudy. In think it is better to use a perfectly filtered transparent oil. Any additives or clouding particles will slow the drying.

Other recommendations were to use raw or boiled oil without any detail about the quality of the oil.

I kept searching and noticed that Swedish cold pressed linseed is often regarded as the best. The climate in southern Sweden is regarded as ideal for growing high quality flax plants, giving high quality oil.

This oil is intended for woodwork, varnish making, house & commercial paint and hand made artists oil paints. The processing varies a little. Some is delivered a little cloudy. Further ahead in the post I can show a method to filter cloudy oil.

It was very difficult to buy online directly from Sweden so I purchased some from Germany and the USA.

Below are 4 oils from Dictum, Kremer & Sinopia. All these arrived perfectly filtered and you can see how transparent they are in the glass bottles. [image]http://

[/image] [image]http://

[/image] [image]http:// [/image]

[/image]All these seem to be equally good. All 3 companies were easy to buy from online. The websites should come up if you google the name but if you can't get them let me know and I can post the links. Sinopia is in USA, the other 2 are in Germany, and Kremer also has a USA division. For Australia deal direct with the German shop as the distributers here are too slow etc.

It's taking a long time to compose all this, getting a bit hungry for dinner now, so i will post the next section tomorrow re filtering cloudy oil, using the psyllium husk visible in one image, and infusing alkanet into it.

I will add a bit here I forgot yesterday about the Swedish oils from Dictum & Kremer Pigmente. They also offer BLO or linseed varnish made from the Swedish cold pressed oil. I don't have any yet as my current interest is in adding the driers myself to the pure oil. This BLO from Dictum or Kremer would be better quality than the regular BLO available here in OZ. The pure oils and some of the BLO have no shipping restrictions. You will also see some tung oil here.

LINKS-

Kremer Pigmente http://www.kremer-pigmente.com/en/mediums-binders-und-glues/

Dictum https://www.dictum.com/en/surfaces

Sinopia http://www.sinopia.com/VS50017-Cold-Pressed-Linseed-Oil-from-Sweden-best-grade_p_11.html

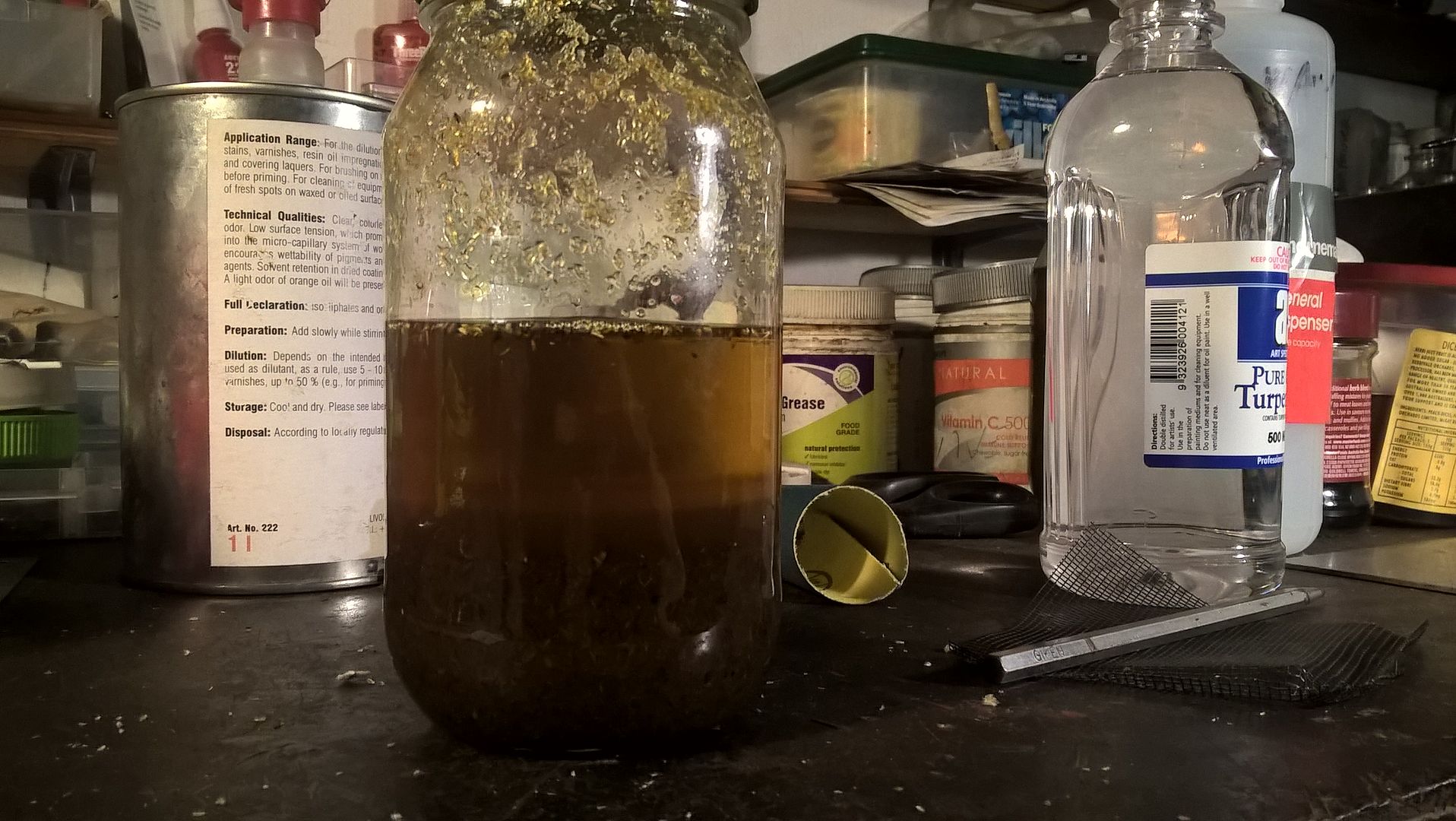

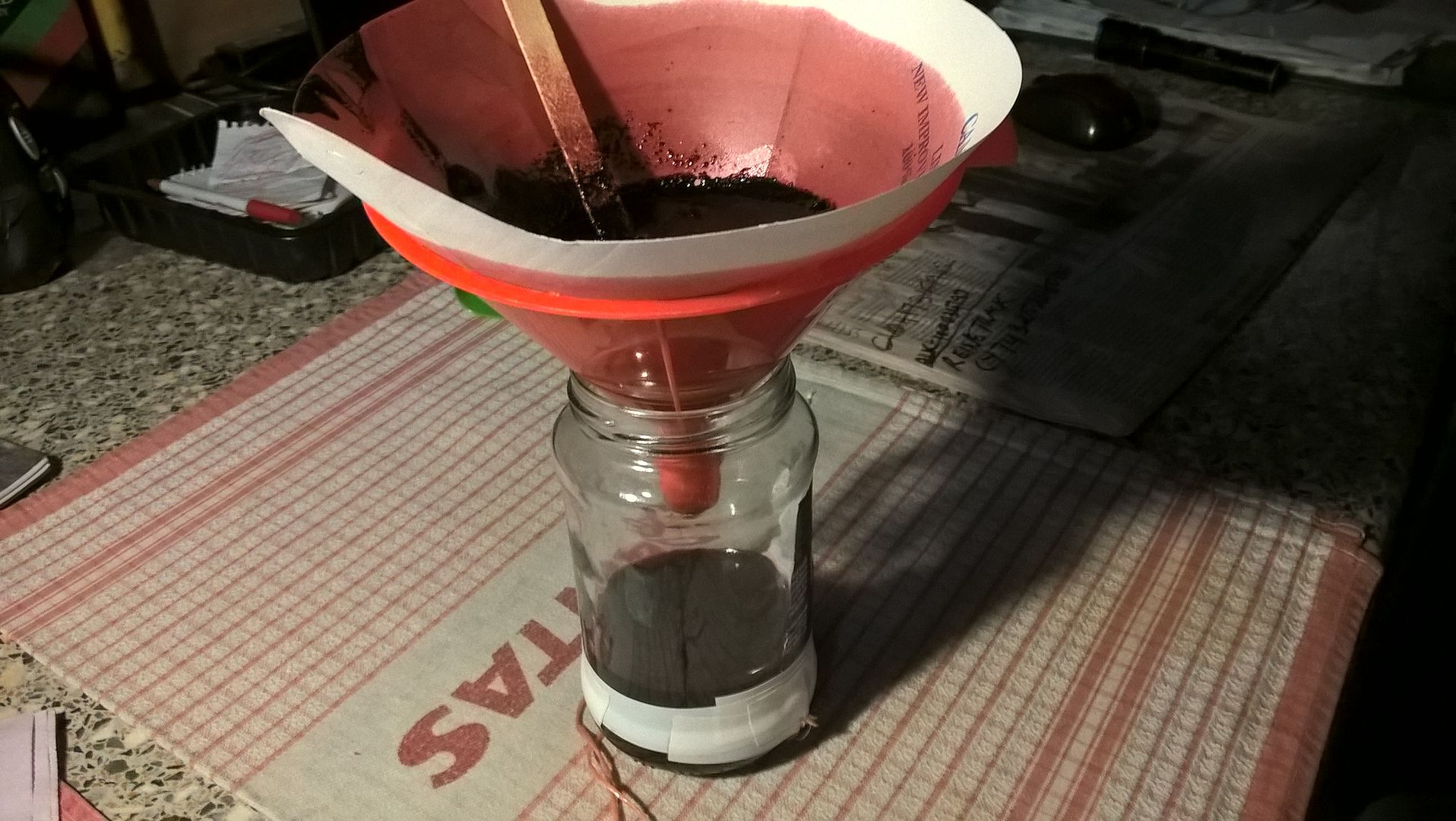

Filtering cloudy cold pressed linseed, images below - I found a method online using Psyllium husk to help filter the oil. The method had some extra stages to further refine the oil for artists use which I felt changed the oil too much so I have just tried the husk stage of the method, with cotton wool as the final very fine filter.

The husk seems to absorb the cloudy particles. Try about 2 tablespoons of husk in 500ml of oil.

Use a bit larger jar to allow expansion of the husk. Shake the jar several times a day for 2-3 days.

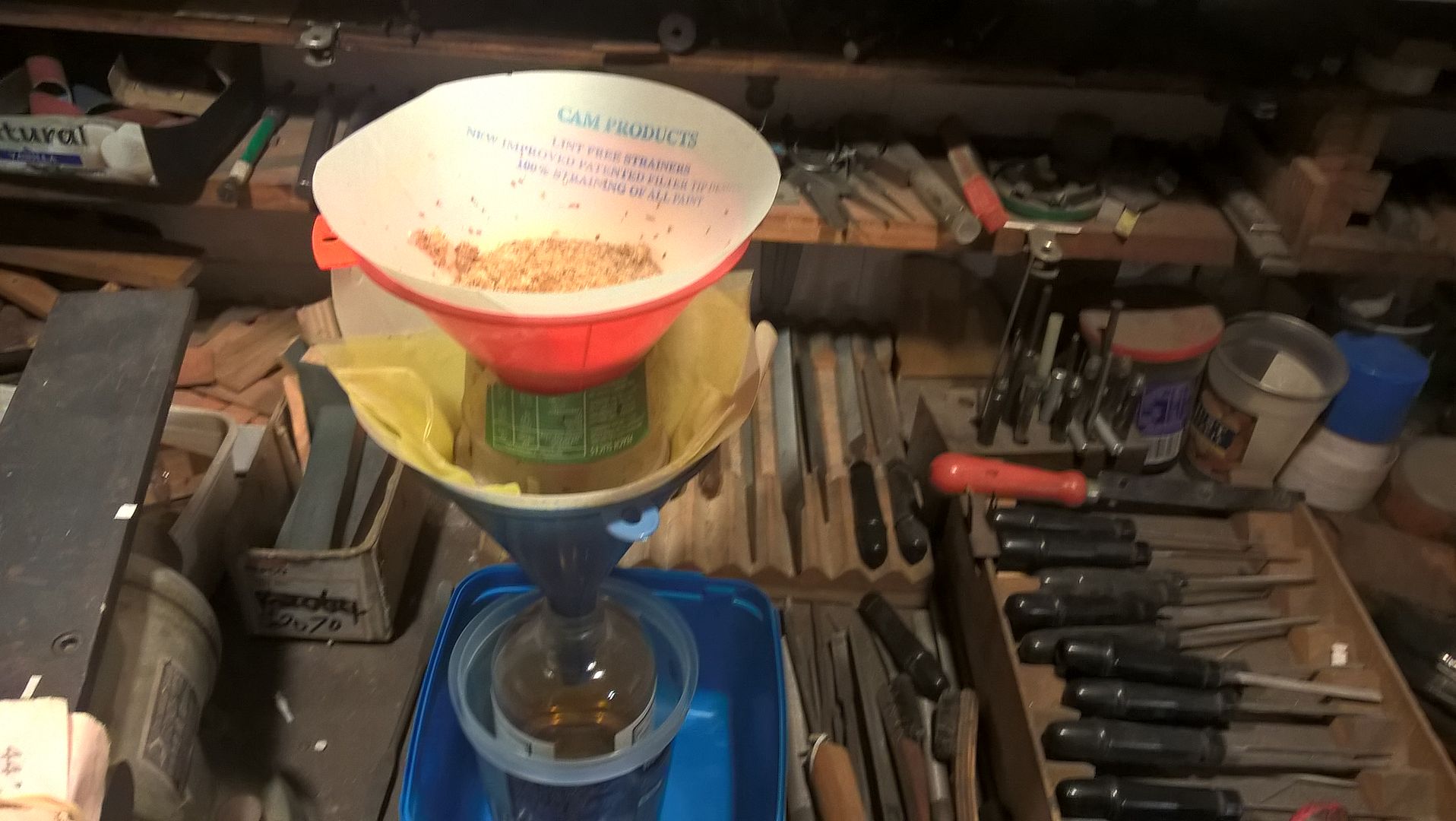

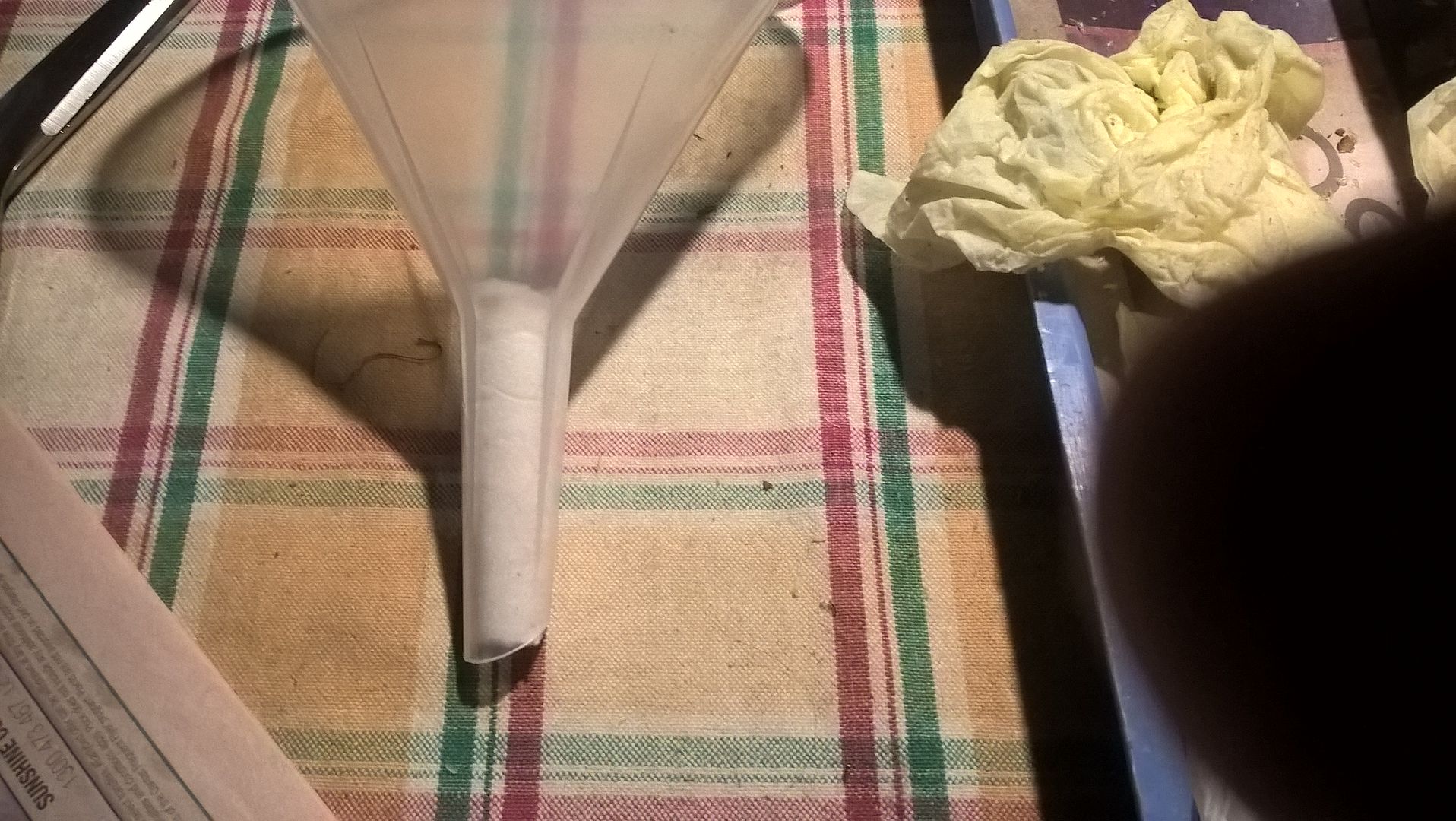

Then filter the husk out using a fine paint filter and cotton wool packed into the stem of the funnel.

The paint filter alone won't filter the oil perfectly transparent. It is used to stop the husk clogging up the wool. Lift the filter a bit out of the funnel sometimes and give the gloopy husk a stir to stop it stiffening too much. This amount of oil will take about 2 days to filter thru the tightly packed wool.

[image]http://

[/image]

[/image] [image]http://

[/image]

[/image] [image]

[/image]

[/image] [image]

[/image]

[/image] [image]

[/image]

[/image] [image]

[/image]

[/image] Below images of a cloudy Swedish cold pressed oil, comparison between filtered and unfiltered.

Filtered on the left. The cloudy particles have settled a little in the unfiltered oil but you can see it is still a little cloudy compared to the filtered oil.

[image]

[/image]

[/image] [image]

[/image]

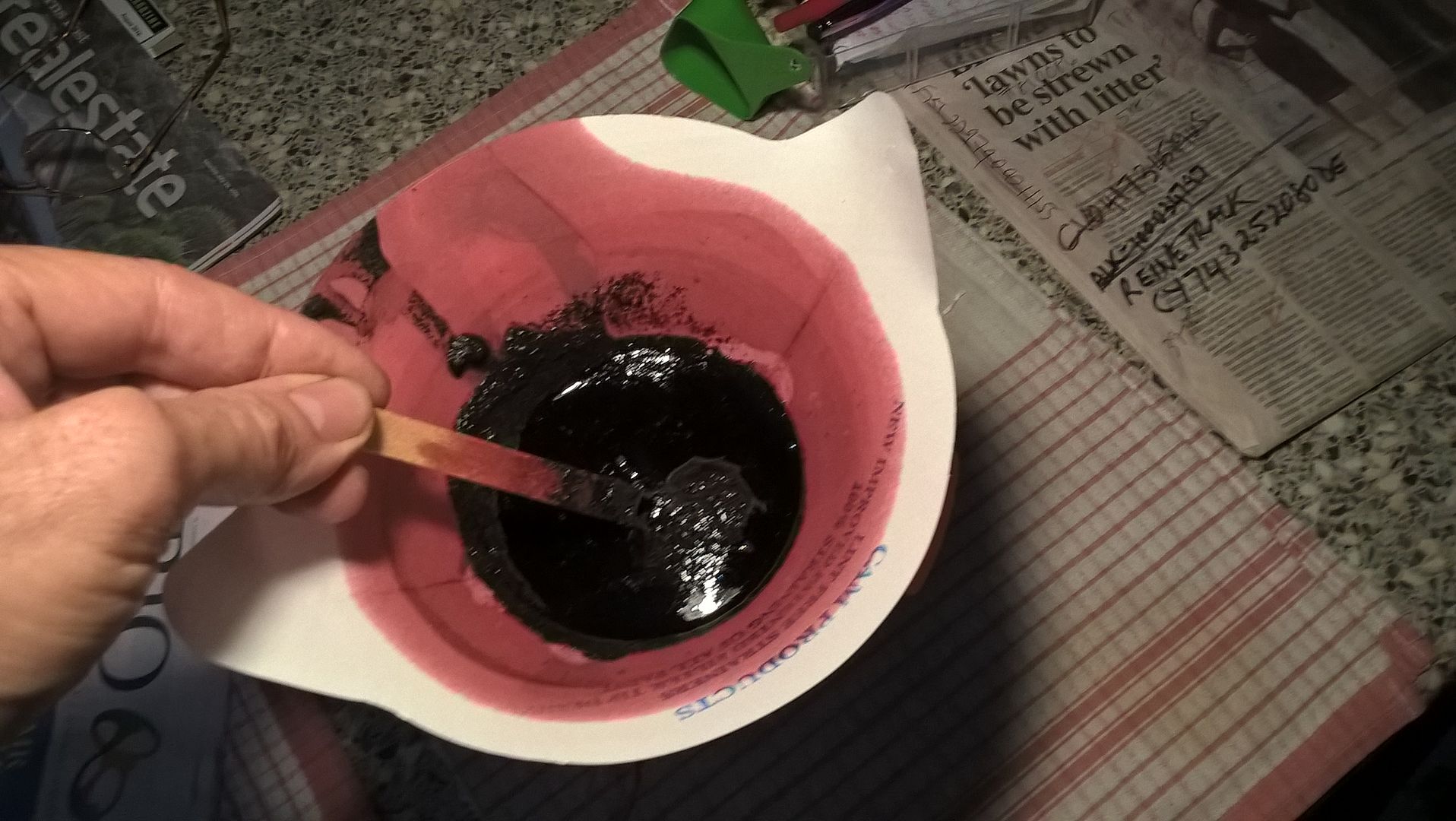

[/image] Alkanet infused linseed oil "Red Oil"- alkanet root extract is a very old dye & stain used in various industries. If you google "alkanet root", "alkanet red linseed oil" etc etc you will find most of the info' I found about it. For many years I thought it was just another type of stain.

More recently I have learnt that compounds in the alkanet reacts with compounds and their ph levels in walnut. When infused into linseed oil and applied to the raw wood for the initial coats it is regarded as the best colour & figure enhancer of walnut.

When infused into thinners or alcohol it can also be used as a stain. I haven't tried it as a stain yet. I purchased some root powder from Aussie Soap Supplies instead of root pieces as the powder gives up the colour much faster. However it is harder to filter out than root pieces.

[image]

[/image]

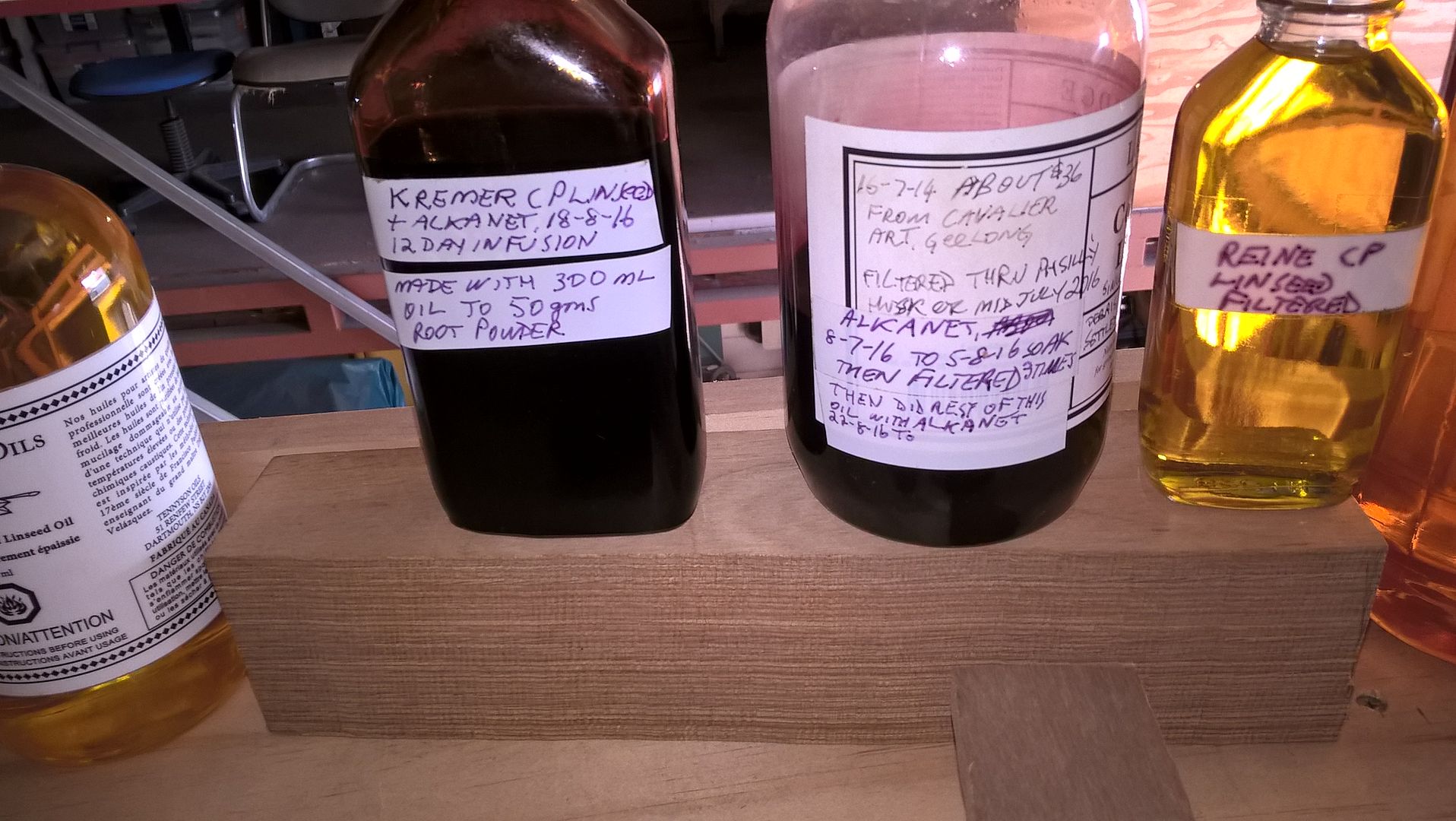

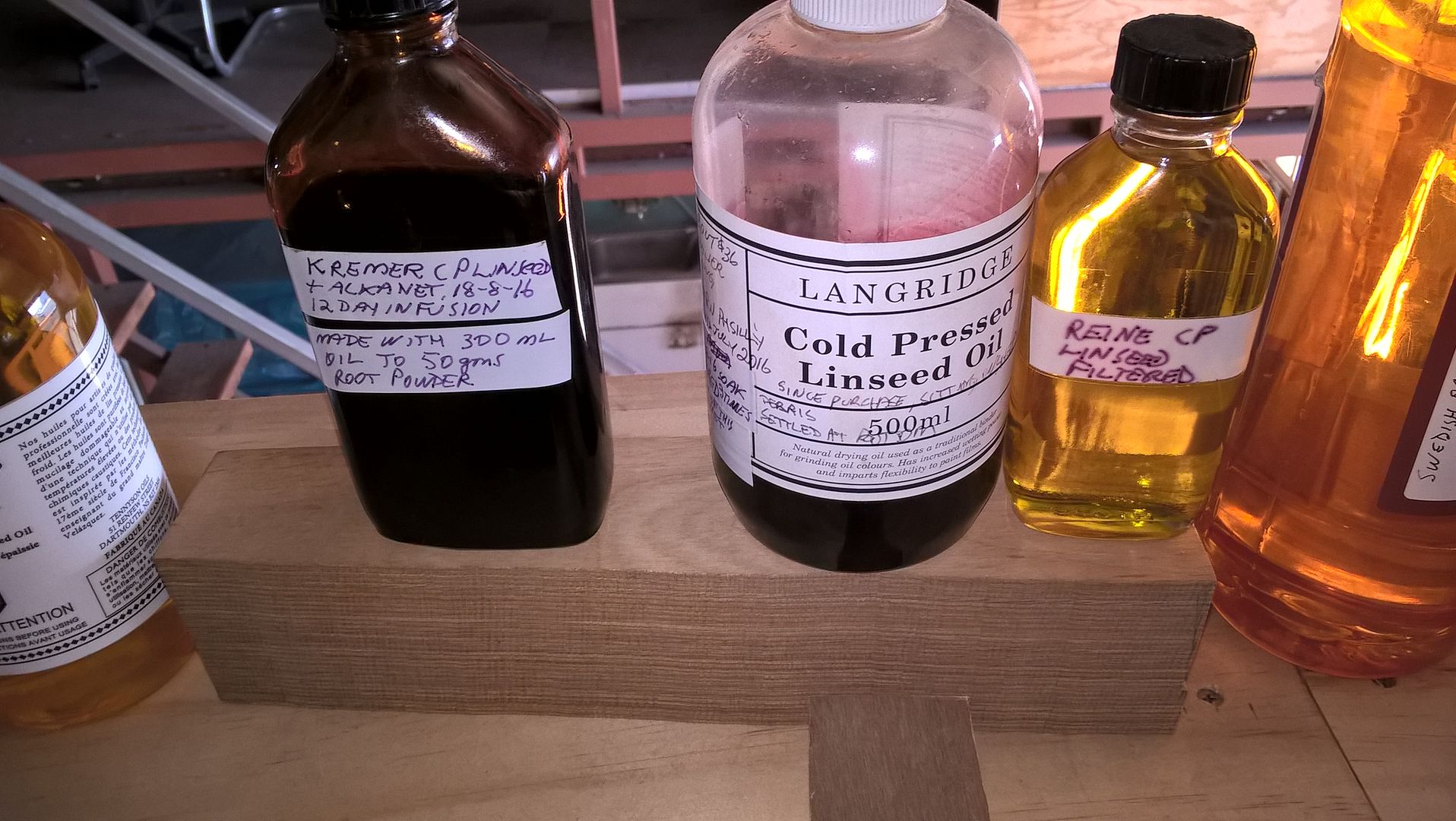

[/image] Below images infusing and filtering. I used about 50gms of root powder to 300ml of oil. I infused one jar for 28 days and a second jar for 12 days. The strength of colour looks the same.

[image]

[/image]

[/image][image]

[/image]

[/image] [image]

[/image]

[/image] The filtering is done thru a fine paint filter and cotton wool in the funnel stem as per the husk filtering. The root powder turns into a sludge. Stir it regularly to stop it stiffening. This sludge has to be filtered out perfectly. You will see it settle to the bottom of the glass bottle if you don't remove all of it. Any sludge in your coats of finish will retard the finish quality.

[image]

[/image] [image]

[/image] [image] [/image]

[/image] The Langridge oil above, an aussie artists grade cold pressed oil I had unopened for a few years. It was quite cloudy with a lot settling out in the bottom. I filtered it and made some red oil with it.

I will continue posting later today or evening.