| AFRO408 |

| (.333 member) |

| 02/11/11 08:56 AM |

|

|

|

|

Here you go mate.

http://www.youtube.com/watch?v=QzxMuM3kOqA&feature=feedu

http://www.youtube.com/watch?v=RrSa4jTvYIQ&feature=feedu

http://www.youtube.com/watch?v=RrSa4jTvYIQ&feature=feedu

http://www.youtube.com/watch?v=_JTUMWdNM2U&feature=feedu

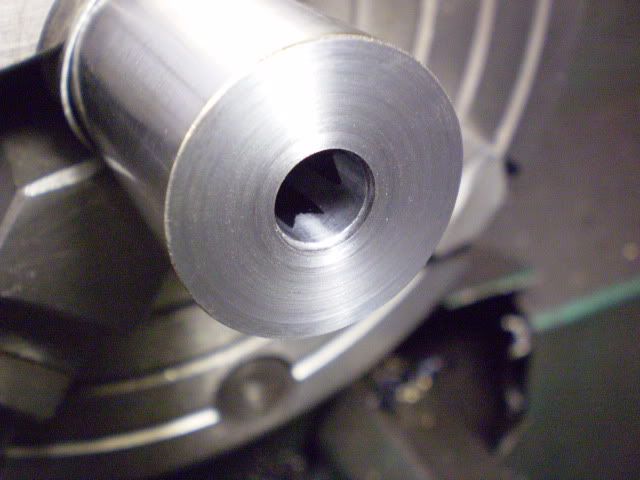

Setting up the barrel shank to cut the extractor relief.

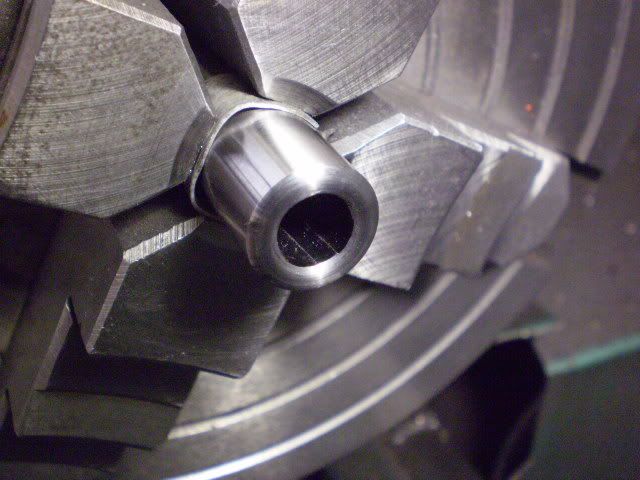

Cutting the relief.

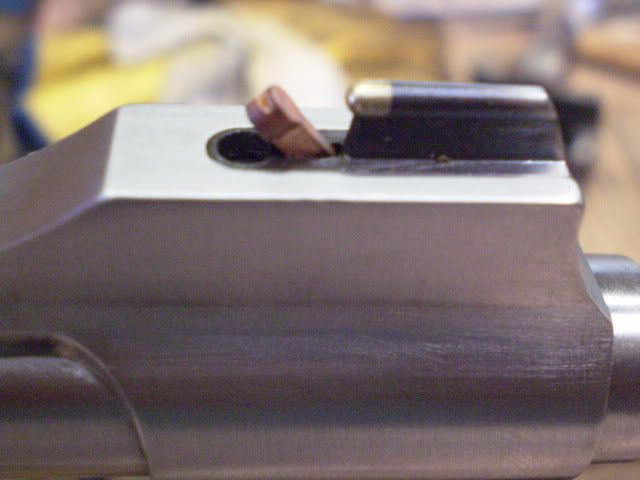

The barrel fits nicely.

I first 'tin' the matching surfaces and clean all traces of the acid flux from the pieces.

The sight bases and sling swivel are soldered on nice and level using 6% Silver solder and resin flux.

I then clean all the excess solder off with a soft chisel, diamond hone and emery cloth lubed with Kerosene.

Barrel in the white, ready for sight regulation and bluing.

The original bedding was good, but needed relieving behind the square lug below the rear tang. This is a common problem that I encounter and on a large cal rifle, contact here will result in splitting the wrist of the stock, or removing a complete wedge of wood.

A mortice was cut for the secondary recoil lug and some wood from the side of the channel for the sight base.

Front Night sight was fitted and some metal needed to be removed from the bottom of the dovetail, to allow the flip up night sight to work smoothly.

Rear sight leaf was fitted and will be regulated to 50m

The rear of the sight bases was stippled as well.

The bolt release lever knob was built up with weld, shaped and knurled.

Talley cross bolt was fitted behind the recoil lug and then it and the bolt release were Nitre blued.